Page 15: of Maritime Reporter Magazine (February 1981)

Read this page in Pdf, Flash or Html5 edition of February 1981 Maritime Reporter Magazine

foundation. A slewing ring fitted to the base is capable of sustain- ing vertical load and tilting mo- ment. The jib is a steel fabrica- tion incorporating the bearings for the pivot pins on the yoke and sheaves for the wire ropes.

For transfer of oil at sea, Schat has developed its "Flow Boom" crane that handles single or twin hoses, with operating enve- lopes that consider the relative positions between ship mani- folds. Flow capacity for crude oil through 20-inch hose is 6,000 tons per hour; through 24-inch pipe construction flow boom, capacity is 12,000 tons per hour. Flow ve- locity is 48 feet per second at pressures up to 150 psi.

TBW

INDUSTRIES

Versatility has never been more in demand in the maritime indus- try than it is today, and this is what characterizes TBW Indus- tries' philosophy in the develop- ment and marketing of its deck

Write 257 on Reader Service Card machinery products for the 1980s, according to Robert M. Thomp- son, president of the Houma, La. company.

The products of TBW's SMAT-

CO Division have long been syn- onymous with the offshore indus- try. Its original line of equipment centered around anchor-handling/ towing winches. Within a short time span in the early 70s it had expanded to include a complete line of machinery ranging from anchor windlasses to stern rollers.

As the quest for oil moved from the calm, shallow waters of the Gulf of Mexico to the harsh environment of the North Sea and the deepwater exploration in

Southeast Asia, SMATCO earned its reputation for toughness and durability. It is this type of work that led SMATCO to its latest development: caliper/disc brakes and clutches. The refinement of this system has opened new op- tions to the operator faced with the tasks of heavier loads in deeper waters. Taking the heart of the brake system to task,

SMATCO now offers disc brakes on all of its winches and related equipment.

Another advancement in the state of the art has been the de- sign of a double-drum waterfall winch designed especially for tug- boats. Traditionally, waterfall winches were unacceptable be- cause of height. SMATCO's new low-profile winch has eliminated this major problem and at the same time reduced the overall width by nearly 50 percent. This offers the operator a larger and safer working area, as well as the advantage of always working closer to the center line of the vessel.

Recognizing the U.S. maritime industry as an area needing the same level of quality as the off- shore oil operators, SMATCO launched an effort to become a sought-after supplier. Since its initial effort in 1978, the com- pany has secured mooring equip- ment orders from major ship- yards such as Sun Ship, NASSCO,

Avondale, Newport News, and

General Dynamics. Ships include

RO/'ROs, product carriers, and dredges.

A further development has been the SMATCO-Samson range of soft rope, twin capstan type trac- tor winches. Originally developed (continued on page 18)

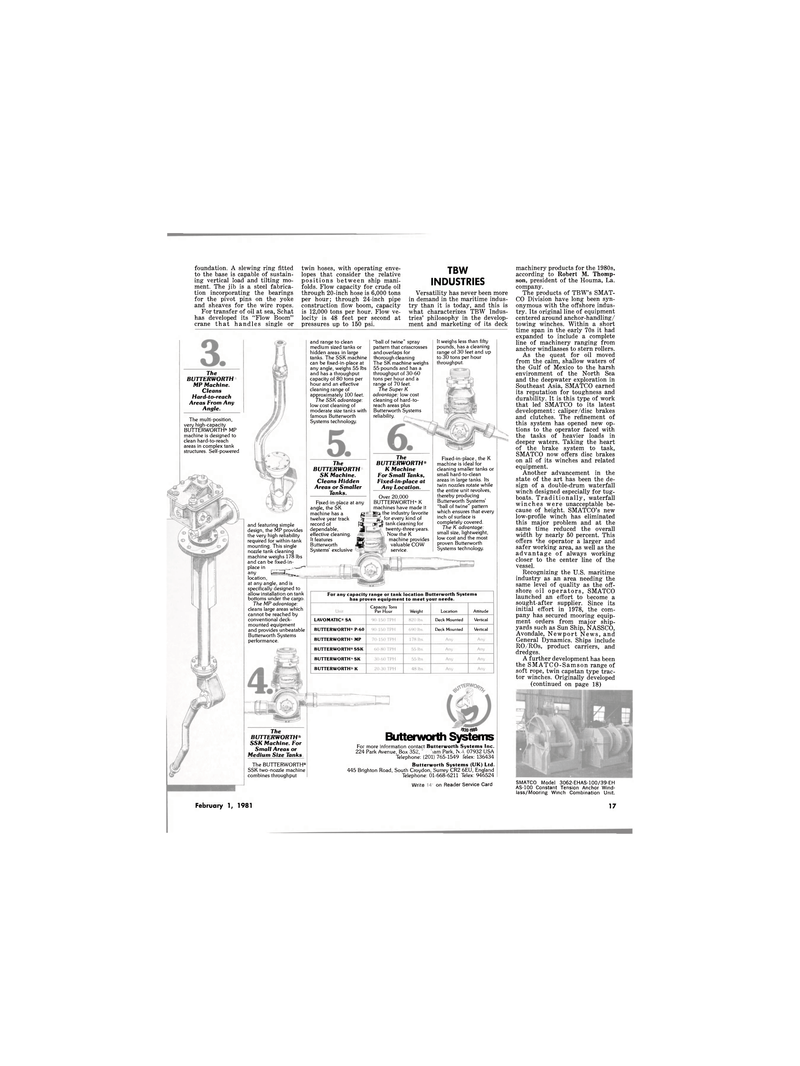

SMATCO Model 3062-EHAS-100/39-EH

AS-100 Constant Tension Anchor Wind- lass/Mooring Winch Combination Unit.

It weighs less than fifty pounds, has a cleaning range of 30 feet and up to 30 tons per hour throughput. "ball of twine" spray pattern that crisscrosses and overlaps for thorough cleaning

The SK machine weighs 55 pounds and has a throughput of 30-60 tons per hour and a range of 70 feet.

The SuperK aduantage: low cost cleaning of hard-to- reach areas plus

Butterworth Systems reliability. and range to clean medium sized tanks or hidden areas in large tanks. The SSK machine can be fixed-in-place at any angle, weighs 55 lbs and has a throughput capacity of 80 tons per hour and an effective cleaning range of approximately 100 feet.

The SSK aduantage: low cost cleaning of moderate size tanks with famous Butterworth

Systems technology.

The

BUTTERWORTH

MP Machine.

Cleans

Hard-to-reach

Areas From Any

Angle.

The multi-position, very high-capacity

BUTTERWORTH91 MP machine is designed to clean hard-to-reach areas in complex tank structures. Self-powered

The

BUTTERWORTH®

K Machine

For Small Tanks,

Fixed-in-place at

Any Location.

Fixed-in-place, the K machine is ideal for cleaning smaller tanks or small hard-to-clean areas in large tanks. Its twin nozzles rotate while the entire unit revolves, thereby producing

Butterworth Systems' "ball of twine" pattern which ensures that every inch of surface is completely covered.

The K aduantage: small size, lightweight, low cost and the most proven Butterworth

Systems technology.

The

BUTTERWORTH

SK Machine.

Cleans Hidden

Areas or Smaller

Tanks. Over 20,000

BUTTERWORTH4 K machines have made it

JS the industry favorite ^g for every kind of pr-Jl tank cleaning for twenty-three years.

Now the K machine provides valuable COW service.

Fixed-in-placs at any angle, the SK machine has a ^ twelve year track Sj record of pit dependable, jj effective cleaning.

It features SE

Butterworth Jp|

Systems' exclusive and featuring simple design, the MP provides the very high reliability required for within-tank mounting. This single nozzle tank cleaning machine weighs 178 lbs and can be fixed-in- place in __ . —^ any EHseg*^ location, at any angle, and is specifically designed to allow installation on tank bottoms under the cargo.

The MP aduantage: cleans large areas which cannot be reached by conventional deck- mounted equipment and provides unbeatable

Butterworth Systems performance.

For any capacity range or tank location Butterworth Systems has proven equipment to meet your needs.

Capacity Tons

Per Hour Attitude Weight Location

Deck Mounted Vertical LAVOMATIC* SA

BUTTERWORTH * P-60 Deck Mounted Vertical

BUTTERWORTH^ MP

BUTTERWORTH * SSK

BUTTERWORTH* SK

BUTTERWORTH* K '930-198® Butterworth Systems

For more information contact Butterworth Systems Inc. 224 Park Avenue, Box 352, ' 'am Park, N..i. 07932 USA

Telephone: (201) 765-1549 Telex: 136434

Butterworth Systems (UK) Ltd. 445 Brighton Road, South Croydon, Surrey CR2 6EU, England

Telephone: 01-668-6211 Telex: 946524

The

BUTTERWORTH®

SSK Machine. For

Small Areas or

Medium Size Tanks

The BUTTERWORTH®

SSK two-nozzle machine combines throughput

February 1, 1981 17

14

14

16

16