Page 18: of Maritime Reporter Magazine (March 15, 1981)

Read this page in Pdf, Flash or Html5 edition of March 15, 1981 Maritime Reporter Magazine

Avondale To Acquire

New $50-Million Drydock

For Ship Repair Work

Avondale Shipyards, a subsid- iary of Ogden Corporation, an- nounced that it will double its repair capacity through the con- struction and equipping of an ad- ditional floating drydock and sup- port facility. The new $50-million drydock will enable Avondale to undertake an increased volume of repair work not possible with its existing facilities. Avondale's repair facilities have been oper- ating substantially at maximum capacity for the past 10 years, and their current revenues ex- ceed $60 million annually.

The new drydock will be capa- ble of providing repair services for almost all vessels that call at the Port of New Orleans, and will be located at the Main Yard where it is expected to employ approximately 500 workers. It will be about 650 feet long and 150 feet wide, with a lifting ca- pacity of 23,000 tons, and can be expanded if desired.

Albert A. Bossier Jr., Avon- dale's president, stated that there is substantial business for the new drydock, and that he expects

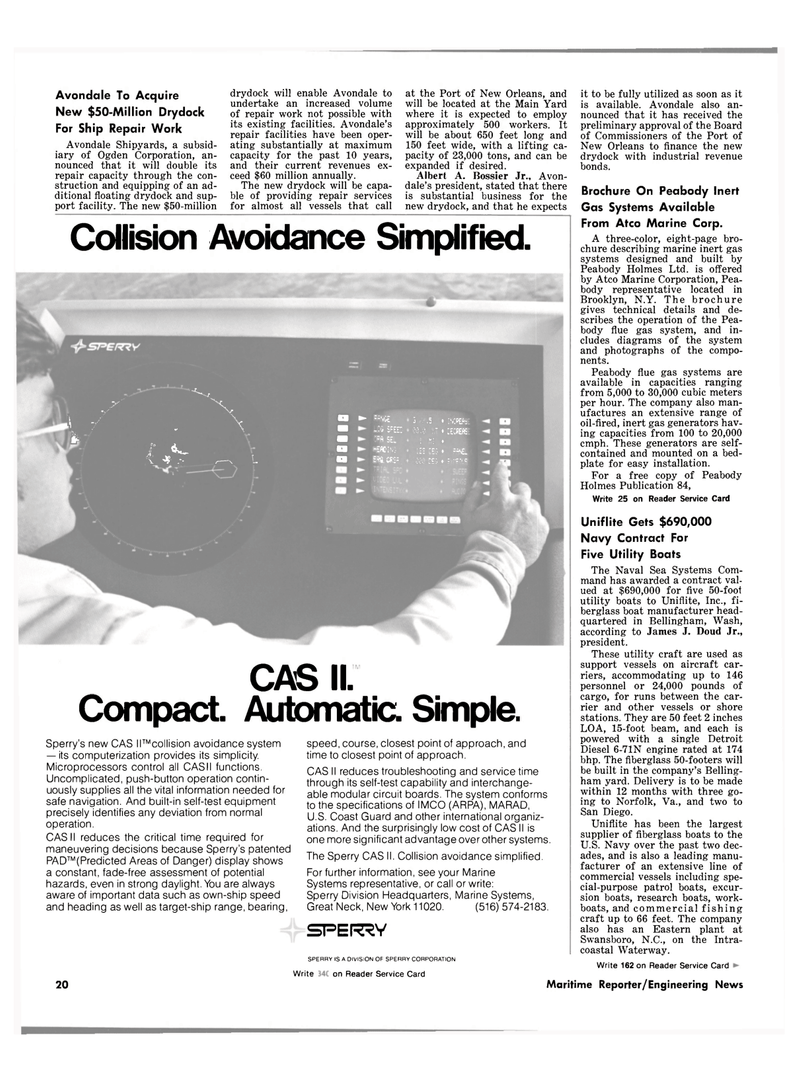

Collision Avoidance Simplified. "r" >r X v' V

I -/ \ a • RFSCE; 3 -v.5 • INCREf: i „ \ •

LOiSPEED 00.0 KT « OECSEK k IB :p|sel I hi * / ^ a -EAC-INO 123 OEO • PflNEL \ * L a WCRSR 000 OK » SYMBOLS

CAS II. Compact. Automatic. Simple.

Sperry's new CAS ll™collision avoidance system — its computerization provides its simplicity.

Microprocessors control all CASH functions.

Uncomplicated, push-button operation contin- uously supplies all the vital information needed for safe navigation. And built-in self-test eguipment precisely identifies any deviation from normal operation.

CASH reduces the critical time required for maneuvering decisions because Sperry's patented

PAD™(Predicted Areas of Danger) display shows a constant, fade-free assessment of potential hazards, even in strong daylight. You are always aware of important data such as own-ship speed and heading as well as target-ship range, bearing, speed, course, closest point of approach, and time to closest point of approach.

CAS II reduces troubleshooting and service time through its self-test capability and interchange- able modular circuit boards. The system conforms to the specifications of IMCO (ARPA), MARAD,

U.S. Coast Guard and other international organiz- ations. And the surprisingly low cost of CAS II is one more significant advantage over other systems.

The Sperry CAS II. Collision avoidance simplified.

For further information, see your Marine

Systems representative, or call or write:

Sperry Division Headquarters, Marine Systems,

Great Neck, New York 11020. (516) 574-2183.

SPERRY

SPERRY IS A DIVISION OF SPERRY CORPORATION

Write 299 on Reader Service Card 20 it to be fully utilized as soon as it is available. Avondale also an- nounced that it has received the preliminary approval of the Board of Commissioners of the Port of

New Orleans to finance the new drydock with industrial revenue bonds.

Brochure On Peabody Inert

Gas Systems Available

From Atco Marine Corp.

A three-color, eight-page bro- chure describing marine inert gas systems designed and built by

Peabody Holmes Ltd. is offered by Atco Marine Corporation, Pea- body representative located in

Brooklyn, N.Y. The brochure gives technical details and de- scribes the operation of the Pea- body flue gas system, and in- cludes diagrams of the system and photographs of the compo- nents.

Peabody flue gas systems are available in capacities ranging from 5,000 to 30,000 cubic meters per hour. The company also man- ufactures an extensive range of oil-fired, inert gas generators hav- ing capacities from 100 to 20,000 cmph. These generators are self- contained and mounted on a bed- plate for easy installation.

For a free copy of Peabody

Holmes Publication 84,

Write 25 on Reader Service Card

Uniflite Gets $690,000

Navy Contract For

Five Utility Boats

The Naval Sea Systems Com- mand has awarded a contract val- ued at $690,000 for five 50-foot utility boats to Uniflite, Inc., fi- berglass boat manufacturer head- quartered in Bellingham, Wash, according to James J. Doud Jr., president.

These utility craft are used as support vessels on aircraft car- riers, accommodating up to 146 personnel or 24,000 pounds of cargo, for runs between the car- rier and other vessels or shore stations. They are 50 feet 2 inches

LOA, 15-foot beam, and each is powered with a single Detroit

Diesel 6-71N engine rated at 174 bhp. The fiberglass 50-footers will be built in the company's Belling- ham yard. Delivery is to be made within 12 months with three go- ing to Norfolk, Va., and two to

San Diego.

Uniflite has been the largest supplier of fiberglass boats to the

U.S. Navy over the past two dec- ades, and is also a leading manu- facturer of an extensive line of commercial vessels including spe- cial-purpose patrol boats, excur- sion boats, research boats, work- boats, and commercial fishing craft up to 66 feet. The company also has an Eastern plant at

Swansboro, N.C., on the Intra- coastal Waterway.

Write 162 on Reader Service Card

Maritime Reporter/Engineering News

17

17

19

19