Page 10: of Maritime Reporter Magazine (April 1981)

Read this page in Pdf, Flash or Html5 edition of April 1981 Maritime Reporter Magazine

Rio Marine Asks Title XI

On Eight Tank Barges

To Cost $4.8 Million

Rio Marine, Inc., Houston, has applied to the Maritime Adminis- tration for a Title XI guarantee to aid in financing the construc- tion of eight 200-foot-long, dou- ble-skinned chemical tank barges.

Each is to have a capacity of 10,000 barrels and will be oper- ated on inland rivers and the in- tracoastal waters of the U.S. Gulf area.

Platzer Shipyard of Houston is building the vessels, with the first to be delivered July 1 and the others at one-month intervals thereafter. The estimated cost of the barges has been set at $4,- 860,519, with the requested guar- antee for 87Vo percent of that amount, or $4,200,000.

Marine Industries Corp.

Will Market NABRICO

Products In St. Louis

Marine Industries Corporation has opened an office in St. Louis making Nashville Bridge Compa- ny (NABRICO) products readily available in that area for the first time in several years. Located at 1544 Autumn Leaf Drive in Man- chester, Mo., the office will be headed by Lonnie Jacobs, accord- ing to Byron T. Bailey, president of Marine Industries. The tele- phone number for the new office is (318) 225-6507.

With the opening of the new office, the company now serves the Upper Mississippi River area as well as the Ohio Valley area.

Marine Industries Corporation, founded in 1978, is headquartered in Clarksville, Ind. The company has been a stocking distributor for NABRICO for approximately two years, handling winches, hatches, and all other standard deck fittings sold by Nashville

Bridge Company.

NABRICO is a wholly owned subsidiary of The American Ship

Building Company, Tampa, Fla.

Headquartered in Nashville,

Tenn., NABRICO has been in the marine field for more than 60 years and is primarily concerned with the design, engineering, and construction of barges, drydocks, and towboats. The company is a major supplier of marine deck hardware to the entire marine industry. NABRICO, which has plants in Nashville and Ashland

City, Tenn., pioneered in the de- sign and building of much of the modern equipment used on rivers today.

American Aero To Build

New Facility That Will

Double Current Capacity

American Aero, Inc., a subsid- iary of Weatherford Internation- al, will more than double its cur- rent production capacity by build- ing a new manufacturing plant, warehouse, and office complex in northwest Houston. The AAI plant proposal, more than a year in the planning stages, was ap- proved by Weatherford's board of directors at its last meeting.

Although a site for the new plant has not been announced, company officials are considering several northwest Houston loca- tions, all within 10 miles of the existing plant at 10950 Old Katy

Road. AAI's operations currently occupy seven acres of land in five separate locations, but the new plant will put all of the company's

Houston activities under one roof.

The planned facility will most likely be constructed on a 25-acre tract.

American Aero manufactures and markets hydraulic pedestal cranes and high-pressure water blasters. The company's cranes are approved for use aboard any marine vessel, but their compact design has proved particularly at- tractive to the offshore drilling industry. AAI's water blasters are used in a variety of indus- trial cleaning applications.

For more information,

Write 58 on Reader Service Card

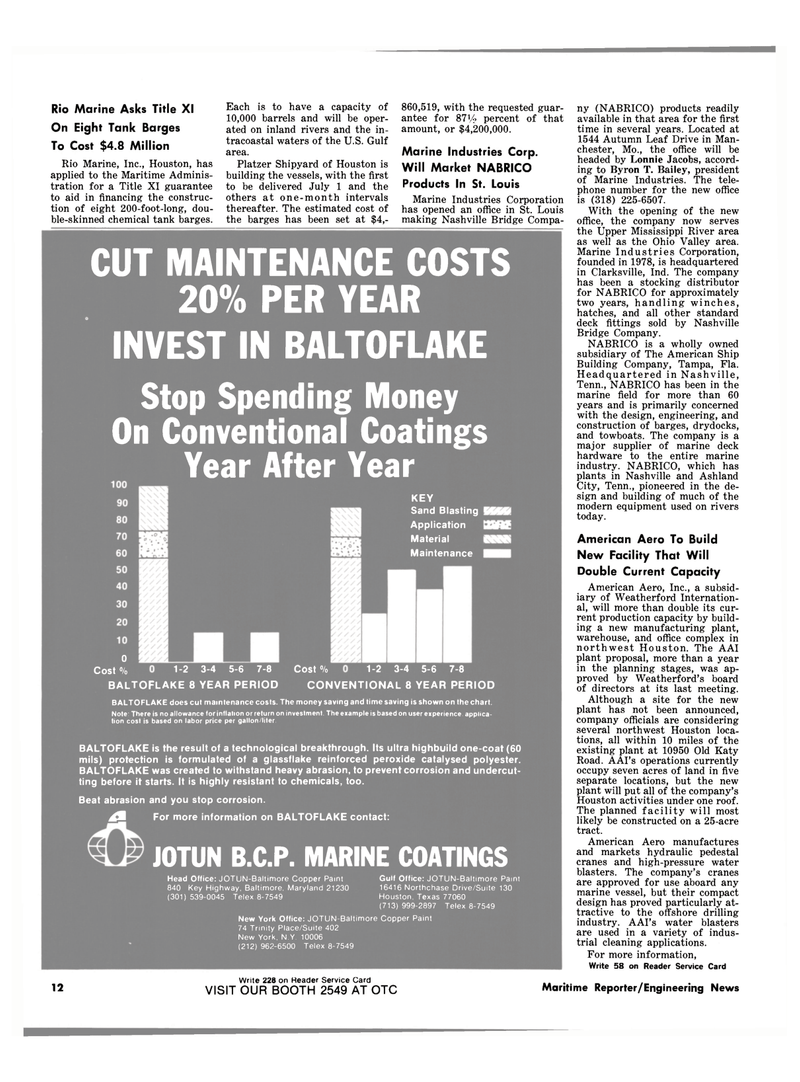

CUT MAINTENANCE COSTS 20% PER YEAR

INVEST IN BALTOFLAKE

Stop Spending Money

On Conventional Coatings

Year After Year

KEY

Sand Blasting

Application

Material

Maintenance 0

Cost % 1-2 3-4 5-6 7-8 Cost % 1-2 3-4 5-6 7-8

BALTOFLAKE 8 YEAR PERIOD CONVENTIONAL 8 YEAR PERIOD

BALTOFLAKE does cut maintenance costs. The money saving and time saving is shown on the chart.

Note: There is no allowance (or inflation or return on investment. The example is based on user experience, applica- tion cost is based on labor price per gallon/liter.

BALTOFLAKE is the result of a technological breakthrough. Its ultra highbuild one-coat (60 mils) protection is formulated of a glassflake reinforced peroxide catalysed polyester.

BALTOFLAKE was created to withstand heavy abrasion, to prevent corrosion and undercut- ting before it starts. It is highly resistant to chemicals, too.

Beat abrasion and you stop corrosion. ^fl For more information on BALTOFLAKE contact:

J0TUN B.C.P. MARINE COATINGS

Head Office: JOTUN-Baltimore Copper Paint 840 Key Highway, Baltimore, Maryland 21230 (301) 539-0045 Telex 8-7549

Gulf Office: JOTUN-Baltimore Paint 16416 Northchase Drive/Suite 130

Houston, Texas 77060 (713) 999-2897 Telex 8-7549

New York Office: JOTUN-Baltimore Copper Paint 74 Trinity Place/Suite 402

New York, N Y. 10006 (212) 962-6500 Telex 8-7549 12

Write 228 on Header Service Card

VISIT OUR BOOTH 2549 AT OTC Maritime Reporter/Engineering News

9

9

11

11