Page 22: of Maritime Reporter Magazine (April 1981)

Read this page in Pdf, Flash or Html5 edition of April 1981 Maritime Reporter Magazine

Hayward Offers New Line

Of Valve Operating Stands —Literature Available

A new series of welding type, fabricated valve operating stands, used to operate valves below decks, is now being manufactured by the Marine Products Division of Hayward Manufacturing Com- pany, Elizabeth, N.J. Two stand- ard heights, 14-inch and 24-inch, are available. Each can be sup- plied with stainless-steel stems in 1, 1*4, or lVo-inch diameters.

Handwheels are available in sev- eral sizes, from 8-inch through 24-inch diameters. Bushings are self-lubricating bronze Oilite. An indicator on the stem moves up and down to show relative open or closed position.

Because of the flexibility of this design, many options are available. The stem may be mod- ified to accommodate each rod or cable coupling for extension be- low decks. The indicator can be designed to coincide with the op- eration of the valve. Special mod- ifications may be supplied on re- quest, including flanged mounting to decks. Delivery is from stock for marine repair jobs, retrofit- ting, or new construction.

For additional information,

Write 48 on Reader Service Card

James Thrane Appointed

VP-Capital Projects For

Santa Fe Engineering

James C. Thrane

James C. Thrane, the man re- sponsible for Santa Fe Engineer- ing Services Company's new equipment construction, has been promoted twice recently. In De- cember 1980 he was named vice president of construction; two months later, he was promoted to vice president of capital proj- ects. He was succeeded as man- ager of construction and repair by Dennis Yenzer. Mr. Thrane joined Santa Fe in 1973 as a con- struction superintendent. Prior to that he was general manager of

PACECO's Gulfport, Miss., man- ufacturing plant.

Automatic Logging System

Developed By NMS—

Literature Available

The tasks of logging ship's con- trol commands, responses, and propulsion system operation can be completely turned over to an automatic printout logging sys- tem developed by National Ma- rine Service Incorporated. The bell logger system automatically prints engine order telegraph commands, responses, throttle po- sition, propeller pitch, and shaft rpm. Data and time are recorded for every control or function. The system is extremely flexible, and any parameters may be selected by the vessel operator. Custom- ization to a specific vessel is said to be easy and economical.

The bell logger system is de- signed for the marine environ- ment, including the printer, whose output is impervious to light, tem- perature, or humidity. Compati- bility with National Marine's master clock system is designed into the automatic logger. Accord- ing to a National Marine spokes- man, the bell logger system is competitively priced and is also compatible with National Ma- rine's monitoring systems for diesel-powered vessels.

For more information and free literature,

Write 53 on Reader Service Card

TRELLCLEAN ®

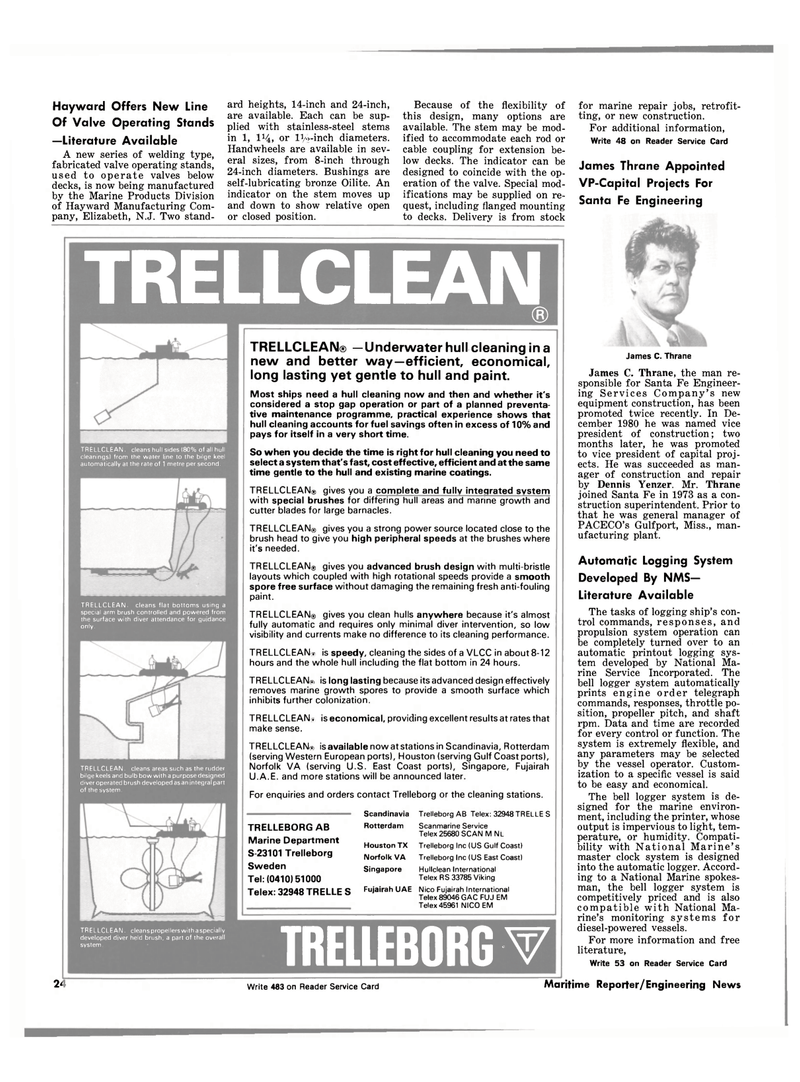

TRELLCLEAN. cleans hull sides (80% of all hull cleanings) from the water line to the bilge keel automatically at the rate of 1 metre per second.

TRELLCLEAN. cleans flat bottoms using a special arm brush controlled and powered from the surface with diver attendance for guidance only.

TRELLCLEAN. cleans areas such as the rudder bilge keels and bulb bow with a purpose designed diver operated brush developed as an integral part of the system.

TRELLCLEAN cleans propellers with a specially developed diver held brush, a part of the overall system

TRELLCLEAN® —Underwater hull cleaning in a new and better way—efficient, economical, long lasting yet gentle to hull and paint.

Most ships need a hull cleaning now and then and whether it's considered a stop gap operation or part of a planned preventa- tive maintenance programme, practical experience shows that hull cleaning accounts for fuel savings often in excess of 10% and pays for itself in a very short time.

So when you decide the time is right for hull cleaning you need to select a system that's fast, cost effective, efficient and at the same time gentle to the hull and existing marine coatings.

TRELLCLEAN® gives you a complete and fully integrated system with special brushes for differing hull areas and marine growth and cutter blades for large barnacles.

TRELLCLEAN® gives you a strong power source located close to the brush head to give you high peripheral speeds at the brushes where it's needed.

TRELLCLEAN® gives you advanced brush design with multi-bristle layouts which coupled with high rotational speeds provide a smooth spore free surface without damaging the remaining fresh anti-fouling paint.

TRELLCLEAN® gives you clean hulls anywhere because it's almost fully automatic and requires only minimal diver intervention, so low visibility and currents make no difference to its cleaning performance.

TRELLCLEAN® is speedy, cleaning the sides of a VLCC in about 8-12 hours and the whole hull including the flat bottom in 24 hours.

TRELLCLEAN® is long lasting because its advanced design effectively removes marine growth spores to provide a smooth surface which inhibits further colonization.

TRELLCLEAN® make sense. is economical, providing excellent results at rates that

TRELLCLEAN® is available now at stations in Scandinavia, Rotterdam (serving Western European ports), Houston (serving Gulf Coast ports),

Norfolk VA (serving U.S. East Coast ports), Singapore, Fujairah

U.A.E. and more stations will be announced later.

For enquiries and orders contact Trelleborg or the cleaning stations.

TRELLEBORG AB

Marine Department

S-23101 Trelleborg

Sweden

Tel: (0410) 51000

Telex: 32948 TRELLES

Scandinavia Trelleborg AB Telex: 32948 TRELLE S

Rotterdam Scanmarine Service

Telex 25680 SCAN M NL

Houston TX Trelleborg Inc (US Gulf Coast)

Norfolk VA Trelleborg Inc (US East Coastl

Singapore Hullclean International

Telex RS 33785 Viking

Fujairah UAE Nico Fujairah International

Telex 89046 GAC FUJ EM

Telex 45961 NICO EM

TRELLEBORG V 24 Write 483 on Reader Service Card Maritime Reporter/Engineering News

21

21

23

23