Page 27: of Maritime Reporter Magazine (April 15, 1981)

Read this page in Pdf, Flash or Html5 edition of April 15, 1981 Maritime Reporter Magazine

Navigation/Communication

Equipment Review — Hose-McCann (continued from page 27) signal and alarm panels, alarm bells, and associated Mil-Spec items.

New products by Hose-McCann include a variety of bells, buzzers, horns, sirens, telephone equip- ment, and accessories manufac- tured in accordance with the lat- est Military Specifications.

For further information,

Write 26 on Reader Service Card

IOTRON cility. It provides a choice of op- erating modes: F1 for direct printing radioteletype, A1 for ra- diotelegraph, A3H for reception on conventional AM receivers,

A3A for reception by public coast stations, and A3J for reception on single-sideband receivers.

The MRU-35A (T) features syn- thesized frequency control that provides 220,000 highly stable transmitting and receiving fre- quencies in the 2 to 25.11 mHz range. The transmitter combines an advanced crystal oscillator and solid state synthesized exciter with a modern, manually tuned linear amplifier to provide large channel capability, economical op- eration, and excellent perform- ance. Rapid frequency changing and tune-up are achieved by the simplified and conveniently grouped operating controls.

For further information,

Write 28 on Reader Service Card

JAPAN RADIO

Japan Radio Company, Ltd. (JRC) has more than 65 years of experience in producing a broad range of marine electronics. JRC can draw on its experience and knowledge from building all types of marine electronics and produce sophisticated satellite communi- (continued on page 30)

The Digiplot line of automatic radar plotting aids is manufac- tured by the IOTRON Corpora- tion of Bedford, Mass. IOTRON was one of the pioneers in the development of collision-avoid- ance equipment, and has special- ized in this field for more than 10 years.

From the very beginning, IO-

TRON was concerned with meet- ing the mariner's real require- ments for radar plotting, and its equipment has always been based on this requirement, not on a minimum standard developed by a regulatory agency. This philos- ophy, together with 1,250 ship years' experience in automatic radar plotting, has resulted in many important features to be found in the Digiplot line of col- lision-avoidance systems.

For example, Digiplot has a fully automatic target acquisi- tion system. Some systems use "guard rings" that only acquire targets automatically at one or two ranges. Digiplot can auto- matically acquire targets wher- ever they appear within the unit's 17-mile tracking range. Other im- portant features include an en- closed cooling system to prevent salt corrosion, a built-in training display to permit training at any time, choice of 20, 40, or 60 tar- get tracking capability, and two- year warranty.

For further information,

Write 27 on Reader Service Card

ITT MACKAY

The ITT Mackay Marine MRU- 35A(T) radioteletype console is a complete high-frequency radio- teletype, radiotelegraph, and ra- diotelephone communication fa-

Write 475 on Reader Service Card

Write 490 on Reader Service Card • nr\i rnrr Hov# We Solved KL/LL I I LA1 A 5 Year Boiler

Advanced jpQj SI a cm in a Prahl

Combustion

Technology

Problem:

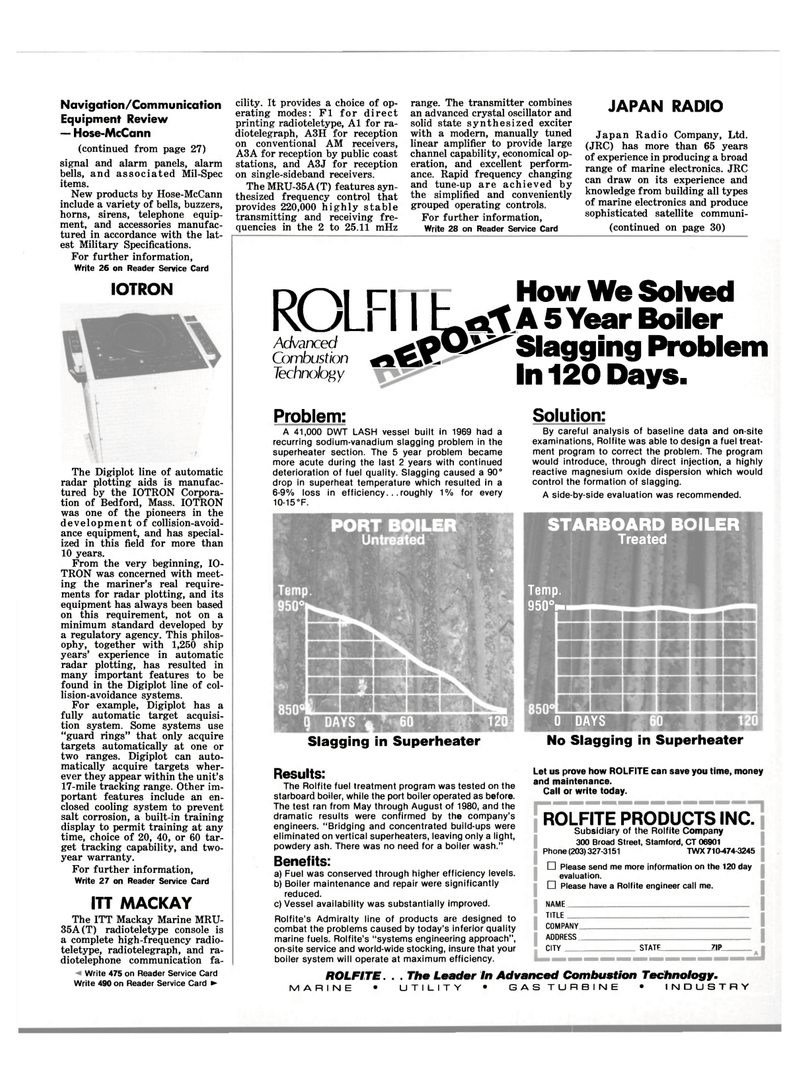

A 41,000 DWT LASH vessel built in 1969 had a recurring sodium-vanadium slagging problem in the superheater section. The 5 year problem became more acute during the last 2 years with continued deterioration of fuel quality. Slagging caused a 90° drop in superheat temperature which resulted in a 6-9% loss in efficiency.. .roughly 1% for every 10-15°F.

Slagging Problem

In 120 Days.

Solution:

By careful analysis of baseline data and on-site examinations, Rolfite was able to design a fuel treat- ment program to correct the problem. The program would introduce, through direct injection, a highly reactive magnesium oxide dispersion which would control the formation of slagging.

A side by-side evaluation was recommended.

STARBOARD BOILER

Treated

Temp. 950°i»

Slagging in Superheater

Results:

The Rolfite fuel treatment program was tested on the starboard boiler, while the port boiler operated as before.

The test ran from May through August of 1980, and the dramatic results were confirmed by the company's engineers. "Bridging and concentrated build-ups were eliminated on vertical superheaters, leaving only a light, powdery ash. There was no need for a boiler wash."

Benefits: a) Fuel was conserved through higher efficiency levels. b) Boiler maintenance and repair were significantly reduced. c) Vessel availability was substantially improved.

Rolfite's Admiralty line of products are designed to combat the problems caused by today's inferior quality marine fuels. Rolfite's "systems engineering approach", on-site service and world-wide stocking, insure that your boiler system will operate at maximum efficiency. 0 DAYS

No Slagging in Superheater

Let us prove how ROLFITE can save you time, money and maintenance.

Call or write today.

ROLFITE PRODUCTS INC.

Subsidiary of the Rolfite Company 300 Broad Street, Stamford, CT 06901

Phone (203) 327-3151 TWX 710-474-3245 • Please send me more information on the 120 day evaluation. • Please have a Rolfite engineer call me.

NAME.

TITLE .

COMPANY,

ADDRESS_

CITY STATEL _ZIP_

ROLFITE. . . The Leader In Advanced Combustion Technology.

MARINE • UTILITY • GAS TURBINE • INDUSTRY

26

26

28

28