Page 7: of Maritime Reporter Magazine (May 1981)

Read this page in Pdf, Flash or Html5 edition of May 1981 Maritime Reporter Magazine

will deal with intermodal trans- port and communication systems between ports and inland centers.

The following will be discussed: survey and control systems for port planning, combined sea/rail and sea/inland shipping trans- port via Hansaport (bulk cargo port) ; Norwegian shipping man- agement systems and the role of goods distribution centers as hinterland links for integrated sea container traffic.

New Brochure Available

On Marine Travelift

Mobile Boat Hoists

Marine Travelift, Sturgeon Bay,

Wis., has completed publication of a new four-page folder including pictures and specifications on its

Model 150AMO boat hoist. The 150-ton-capacity unit is described as the world's largest mobile hoist in existence.

Special illustrations and pic- tures in the new folder describe advanced features such as two- speed hoisting capability, syn- chronized sling control, 90-degree pivot steering, and a special "cruise" control. Complete spec- ifications and essential dimen- sions are also shown.

For a free copy of the brochure,

Write 70 on Reader Service Card

Dravo To Provide Training

For Crews Of People's

Republic's New Towboats

Dravo Corporation has an- nounced the signing of a contract with the Chang Jiang Shipping

Administration of the People's

Republic of China to provide training for the operation of new river towboats. Financial terms of the contract were not disclosed.

Dravo will train Chinese towboat officers aboard towboats operated by Dravo's subsidiary barge line,

Dravo Mechling Corporation.

Dravo is currently near com- pletion of a previously awarded contract to construct, at its Pitts- burgh shipyard, four river tow- boats and 30 barges for the Chi- nese. As the new river transpor- tation equipment is put into serv- ice in China, Dravo will provide on-site technical assistance.

Vander Laan Promoted

To Vice President Of

Soros Associates

Richard W. Vander Laan has been promoted to vice president of Soros Associates, New York

City. Soros, an international con- sulting engineering firm, special- izes in the planning, design and construction management of port facilities, offshore terminals, and bulk material handling systems.

Richard W. Vander Laan

Mr. Vander Laan's initial as- signment in his new position will be as principal in charge of the

Soros-sponsored Transcoal Termi- nal to be built at Marley Neck in

Anne Arundel County, Maryland.

He is well familiar with the Bal- timore area, having been respon- sible for the Soros studies for the expansion of the Chessie's Curtis

Bay shiploading facility, and the proposed rail-to-ship coal transfer terminal at the Canton Docks.

Mr. Vander Laan brings 32 years' experience in the develop- ment and engineering of bulk ma- terial handling systems to the

Marley Neck Terminal project.

Since joining Soros Associates, in 1972, he has been project man- ager for the engineering and con- struction of rail to barge coal transfer terminals on the Ohio

River in West Virginia, Illinois,

Indiana, and Kentucky, and the reconstruction of a petroleum coke shiploading facility in Hou- ston. His overseas projects in- clude a salt loading terminal in

Kandla, India, and a bauxite/ alumina port facility in Brazil.

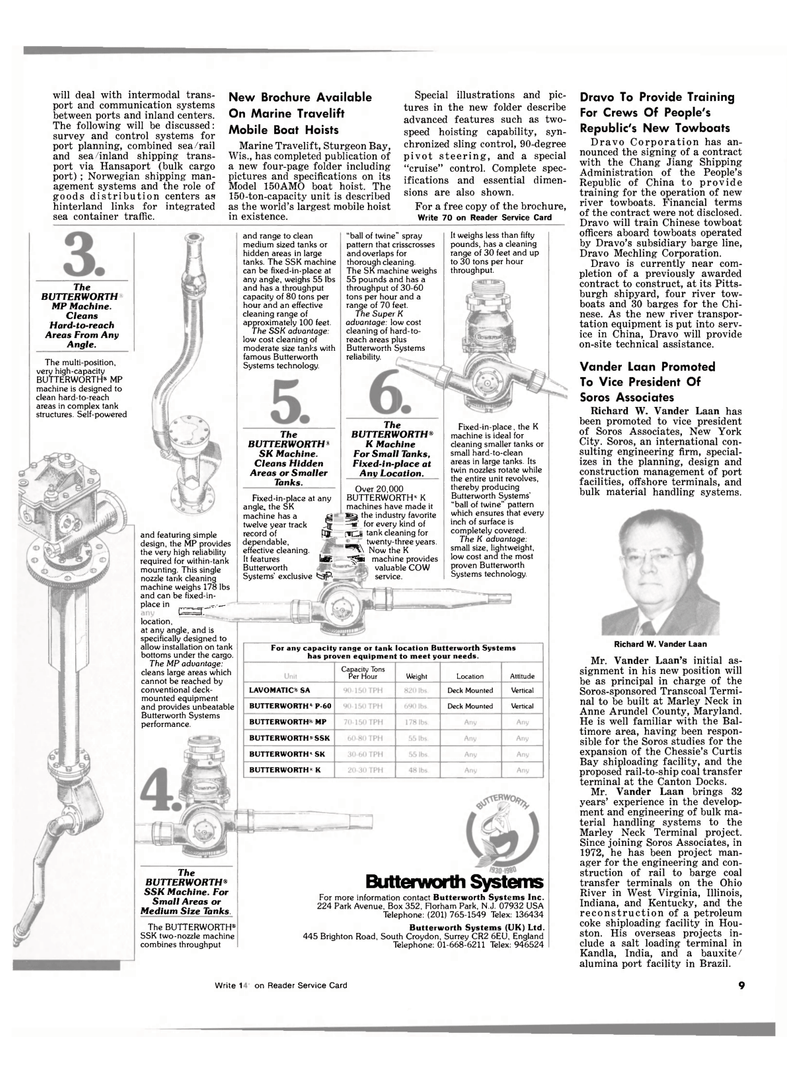

It weighs less than fifty pounds, has a cleaning range of 30 feet and up to 30 tons per hour throughput. and range to clean medium sized tanks or hidden areas in large tanks. The SSK machine can be fixed-in-place at any angle, weighs 55 lbs and has a throughput capacity of 80 tons per hour and an effective cleaning range of approximately 100 feet.

The SSK advantage: low cost cleaning of moderate size tanks with famous Butterworth

Systems technology. "ball of twine" spray pattern that crisscrosses and overlaps for thorough cleaning.

The SK machine weighs 55 pounds and has a throughput of 30-60 tons per hour and a range of 70 feet.

The SuperK advantage: low cost cleaning of hard-to- reach areas plus

Butterworth Systems reliability.

The

BUTTERWORTH

MP Machine.

Cleans

Hard-to-reach

Areas From Any

Angle.

The multi-position, very high-capacity

BUTTERWORTH4 MP machine is designed to clean hard-to-reach areas in complex tank structures. Self-powered

The

BUTTERWORTH®

K Machine

For Small Tanks,

Fixed-in-place at

Any Location.

Over 20,000

BUTTERWORTH * K machines have made it

Sgj. the industry favorite =* for every kind of [TO tank cleaning for twenty-three years. ^\ Now the K "•^m machine provides valuable COW service.

Fixed-in-place, the K machine is ideal for cleaning smaller tanks or small hard-to-clean areas in large tanks. Its twin nozzles rotate while the entire unit revolves, thereby producing

Butterworth Systems' "ball of twine" pattern which ensures that every inch of surface is completely covered.

The K advantage: small size, lightweight, low cost and the most proven Butterworth

Systems technology.

The

BUTTERWORTH >

SK Machine.

Cleans Hidden

Areas or Smaller

Tanks.

Fixed-in-placa at any angle, the SK machine has a jg twelve year track Jjj record of fQt dependable, effective cleaning.

It features Safe

Butterworth

Systems' exclusive tap. and featuring simple design, the MP provides the very high reliability required for within-tank mounting. This single nozzle tank cleaning machine weighs 178 lbs and can be fixed-in- place in ^ __ — location, at any angle, and is specifically designed to allow installation on tank bottoms under the cargo.

The MP advantage: cleans large areas which cannot be reached by conventional deck- mounted equipment and provides unbeatable

Butterworth Systems performance.

For any capacity range or tank location Butterworth Systems has proven equipment to meet your needs.

Capacity Tons

Per Hour Location Attitude Weight

LAVOMATIO SA Vertical Deck Mounted

BUTTERWORTH" P-60 Deck Mounted Vertical

BUTTERWORTH MP

BUTTERWORTH® SSK

BUTTERWORTH" SK

BUTTERWORTH" K

The

BUTTERWORTH®

SSK Machine. For

Small Areas or

Medium Size Tanks.

Butterworth Systems

For more information contact Butterworth Systems Inc. 224 Park Avenue, Box 352, Florham Park, N.J. 07932 USA

Telephone: (201) 765-1549 Telex: 136434

Butterworth Systems (UK) Ltd. 445 Brighton Road, South Croydon, Surrey CR2 6EU, England

Telephone: 01-668-6211 Telex: 946524

The BUTTERWORTH®

SSK two-nozzle machine combines throughput

Write 187 on Reader Service Card 9

6

6

8

8