Page 3: of Maritime Reporter Magazine (June 15, 1981)

Read this page in Pdf, Flash or Html5 edition of June 15, 1981 Maritime Reporter Magazine

Gilbert Snyders Named

VP-Manufacturing At

Marinette Marine

Gilbert J. Snyders

Gilbert J. Snyders was recently appointed to the position of vice president, manufacturing at Mar- inette Marine Corporation, Mar- inette, Wis. Prior to joining Mari- nette, he had been with Newport

News Shipbuilding and Drydock

Company since 1956. At Newport

News he held positions in design; supervisor, machinery; general superintendent; construction manager; manager, production control; and director of interna- tional development.

SPC Coatings Combat

Rising Fuel Costs-

Literature Available

Following the Arab oil embargo in late 1973, International Paint

Company rose to the challenge of combating rising fuel costs with the introduction of the Inter- smooth SPC (self-polishing co- polymer) antifouling coating sys- tem.

The newest member of this family of coatings is Intersmooth

SPC-20. It polishes more slowly than the other products and, in combination with an Intersmooth

SPC-4 or SPC-9 system, allows extended in-service periods be- yond 30 months.

Other members of the Inter- smooth SPC family include SPC- 4, which has the most extensive in-service record, and SPC-9, spe- cially designed for more severe fouling environments and low- activity vessels. The latter has been used widely for ships oper- ating from Japan, where fouling is severe, and for ships that op- erate with repeated idle periods.

For further information and free literature on International's

SPC family of coatings,

Write 51 on Reader Service Card

Ryan-Walsh Bulk Terminal

In New Orleans Resumes

Coal-Handling Operations

New Orleans' ability to garner an increasing share of coal ex- ports received a major boost re- cently with the resumption of full operation of the New Orleans

Bulk Terminal. The Ryan-Walsh

New Orleans Bulk Terminal, as it is now known, opened about six months ahead of schedule after extensive renovation and expansion by Ryan-Walsh Steve- doring Company. Ryan-Walsh re- cently signed a five-year lease with the New Orleans Port Au- thority to operate the facility as a private terminal.

Spokesman for Ryan-Walsh say they expect to handle some 1.75 million tons of coal at the facil- ity during the first year of the contract, with tonnages rising to the 3.5-million level by the fifth year. Their contract contains re- newal options for additional years.

At present coal is moving through New Orleans by mid- stream transfer, a technique prac- ticed by Ryan-Walsh and other stevedoring firms in which float- ing derricks are used to transfer coal from barge to vessels an- chored in the Mississippi River.

Under this system, ships do not have to experience weeks of wait- ing to get to congested berths, saving shippers demurrage that is adding millions of dollars a year to the cost of coal shipments.

Coal is the fastest-growing car- go on the Gulf, say industry spokesmen, turning south because of Atlantic Coast congestion, and will be a major cargo in New

Orleans, Mobile, Alabama, and possibly a few other Gulf ports for many years. Inquiries about the bulk terminal may be made to Ryan-Walsh through its New

Orleans office at (504) 586-0400, or its corporate headquarters in

Mobile at (205) 438-4771 or (800) 633-6758.

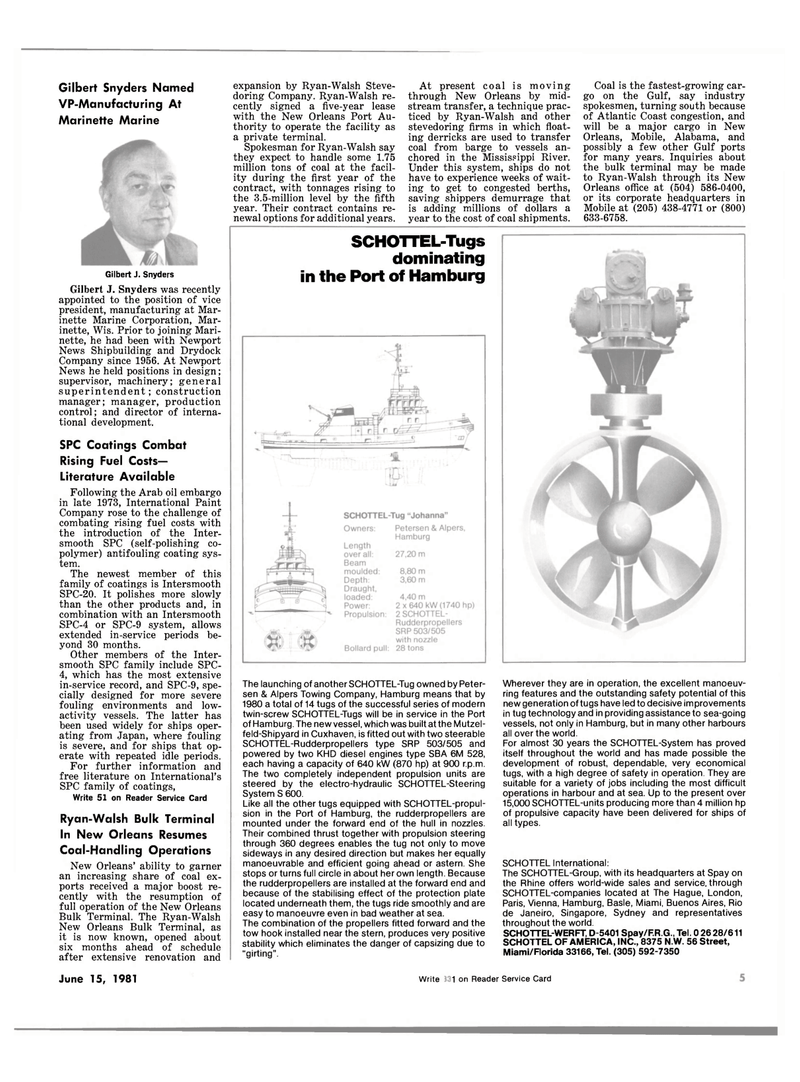

SCHOTTEL-Tugs dominating in the Port of Hamburg

The launching of another SCHOTTEL-Tug owned by Peter- sen & Alpers Towing Company, Hamburg means that by 1980 a total of 14 tugs of the successful series of modern twin-screw SCHOTTEL-Tugs will be in service in the Port of Hamburg. The new vessel, which was built at the Mutzel- feld-Shipyard in Cuxhaven, is fitted out with two steerable

SCHOTTEL-Rudderpropellers type SRP 503/505 and powered by two KHD diesel engines type SBA 6M 528, each having a capacity of 640 kW (870 hp) at 900 r.p.m.

The two completely independent propulsion units are steered by the electro-hydraulic SCHOTTEL-Steering

System S 600.

Like all the other tugs equipped with SCHOTTEL-propul- sion in the Port of Hamburg, the rudderpropellers are mounted under the forward end of the hull in nozzles.

Their combined thrust together with propulsion steering through 360 degrees enables the tug not only to move sideways in any desired direction but makes her equally manoeuvrable and efficient going ahead or astern. She stops or turns full circle in about her own length. Because the rudderpropellers are installed at the forward end and because of the stabilising effect of the protection plate located underneath them, the tugs ride smoothly and are easy to manoeuvre even in bad weather at sea.

The combination of the propellers fitted forward and the tow hook installed near the stern, produces very positive stability which eliminates the danger of capsizing due to "girting".

Wherever they are in operation, the excellent manoeuv- ring features and the outstanding safety potential of this new generation of tugs have led to decisive improvements in tug technology and in providing assistance to sea-going vessels, not only in Hamburg, but in many other harbours all over the world.

For almost 30 years the SCHOTTEL-System has proved itself throughout the world and has made possible the development of robust, dependable, very economical tugs, with a high degree of safety in operation. They are suitable for a variety of jobs including the most difficult operations in harbour and at sea. Up to the present over 15,000 SCHOTTEL-units producing more than 4 million hp of propulsive capacity have been delivered for ships of all types.

SCHOTTEL International:

The SCHOTTEL-Group, with its headquarters at Spay on the Rhine offers world-wide sales and service, through

SCHOTTEL-companies located at The Hague, London,

Paris, Vienna, Hamburg, Basle, Miami, Buenos Aires, Rio de Janeiro, Singapore, Sydney and representatives throughout the world.

SCHOTTEL-WERFT, D-5401 Spay/F.R.G., Tel. 0 26 28/611

SCHOTTEL OF AMERICA, INC., 8375 N.W. 56 Street,

Miami/Florida 33166, Tel. (305) 592-7350

June 15, 1981 Write 210 on Reader Service Card 1 1

2

2

4

4