Page 36: of Maritime Reporter Magazine (July 1981)

Read this page in Pdf, Flash or Html5 edition of July 1981 Maritime Reporter Magazine

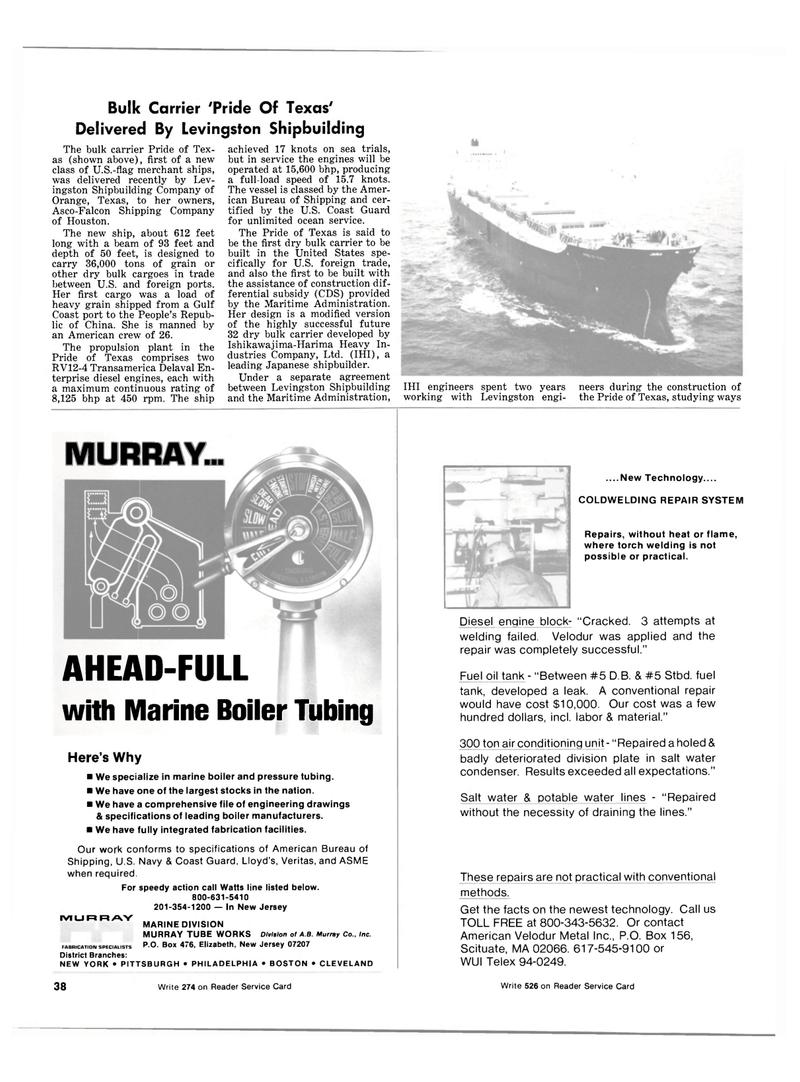

Bulk Carrier 'Pride Of Texas'

Delivered By Levingston Shipbuilding

The bulk carrier Pride of Tex- as (shown above), first of a new class of U.S.-flag merchant ships, was delivered recently by Lev- ingston Shipbuilding Company of

Orange, Texas, to her owners,

Asco-Falcon Shipping Company of Houston.

The new ship, about 612 feet long with a beam of 93 feet and depth of 50 feet, is designed to carry 36,000 tons of grain or other dry bulk cargoes in trade between U.S. and foreign ports.

Her first cargo was a load of heavy grain shipped from a Gulf

Coast port to the People's Repub- lic of China. She is manned by an American crew of 26.

The propulsion plant in the

Pride of Texas comprises two

RV12-4 Transamerica Delaval En- terprise diesel engines, each with a maximum continuous rating of 8,125 bhp at 450 rpm. The ship achieved 17 knots on sea trials, but in service the engines will be operated at 15,600 bhp, producing a full-load speed of 15.7 knots.

The vessel is classed by the Amer- ican Bureau of Shipping and cer- tified by the U.S. Coast Guard for unlimited ocean service.

The Pride of Texas is said to be the first dry bulk carrier to be built in the United States spe- cifically for U.S. foreign trade, and also the first to be built with the assistance of construction dif- ferential subsidy (CDS) provided by the Maritime Administration.

Her design is a modified version of the highly successful future 32 dry bulk carrier developed by

Ishikawajima-Harima Heavy In- dustries Company, Ltd. (IHI), a leading Japanese shipbuilder.

Under a separate agreement between Levingston Shipbuilding and the Maritime Administration,

IHI engineers spent two years neers during the construction of working with Levingston engi- the Pride of Texas, studying ways ....New Technology

COLDWELDING REPAIR SYSTEM

Repairs, without heat or flame, where torch welding is not possible or practical.

Diesel engine block- "Cracked. 3 attempts at welding failed. Velodur was applied and the repair was completely successful."

Fuel oil tank - "Between #5 D.B. & #5 Stbd. fuel tank, developed a leak. A conventional repair would have cost $10,000. Our cost was a few hundred dollars, incl. labor & material."

MURRAY...

AHEAD-FULL with Marine Boiler Tubing

Here's Why • We specialize in marine boiler and pressure tubing. • We have one of the largest stocks in the nation. • We have a comprehensive file of engineering drawings & specifications of leading boiler manufacturers. • We have fully integrated fabrication facilities.

Our work conforms to specifications of American Bureau of

Shipping, U.S. Navy & Coast Guard, Lloyd's, Veritas, and ASME when required.

For speedy action call Watts line listed below. 800-631-5410 201-354-1200 — In New Jersey

IVI l_J Fl Ft AY

FABRICATION SPECIALISTS

District Branches:

NEW YORK • PITTSBURGH

MARINE DIVISION

MURRAY TUBE WORKS Division of A.B Murray Co.. Inc.

P.O. Box 476, Elizabeth, New Jersey 07207 • PHILADELPHIA • BOSTON • CLEVELAND 300Ion airconditioning unit- "Repaired a holed & badly deteriorated division plate in salt water condenser. Results exceeded all expectations."

Salt water & potable water lines - "Repaired without the necessity of draining the lines."

These repairs are not practical with conventional methods.

Get the facts on the newest technology. Call us

TOLL FREE at 800-343-5632. Or contact

American Velodur Metal Inc., P.O. Box 156,

Scituate, MA 02066. 617-545-9100 or

WUI Telex 94-0249. 38 Write 274 on Reader Service Card Write 526 on Reader Service Card

35

35

37

37