Page 49: of Maritime Reporter Magazine (July 1981)

Read this page in Pdf, Flash or Html5 edition of July 1981 Maritime Reporter Magazine

plants. They will provide repairs and mod- ifications that do not require drydocking a destroyer and will carry spare parts, weap- ons, and munitions, and medical and dental personnel.

The first destroyer tender to be completed by NASSCO, USS Yellowstone, was received by the Navy in May 1980. The third and fourth destroyer tenders are scheduled for delivery in November 1981 and May 1983, respectively.

Delta Shipyard Delivers

Inland Drilling Barge

Delta Shipyard of Houma, La., recently delivered the Inland Drill Barge DSD #4 (shown above) to Dean Shank Drilling Com- pany, Inc. of New Orleans. The barge is 210 feet long, 50 feet wide, and 14 feet deep and becomes the fourth such drill barge the company is operating in the Gulf inland oil and gas industry. The new unit is designed to drill to 25,000 feet in water depths to 12 feet.

Drill Barge DSD #4 is the second inland drilling barge constructed by Delta Ship- yard's new construction facility, which has been designed for the construction of drill barges, cargo barges, and offshore deck barges.

Dome Petroleum Orders Drill

From Cammed Laird Yard

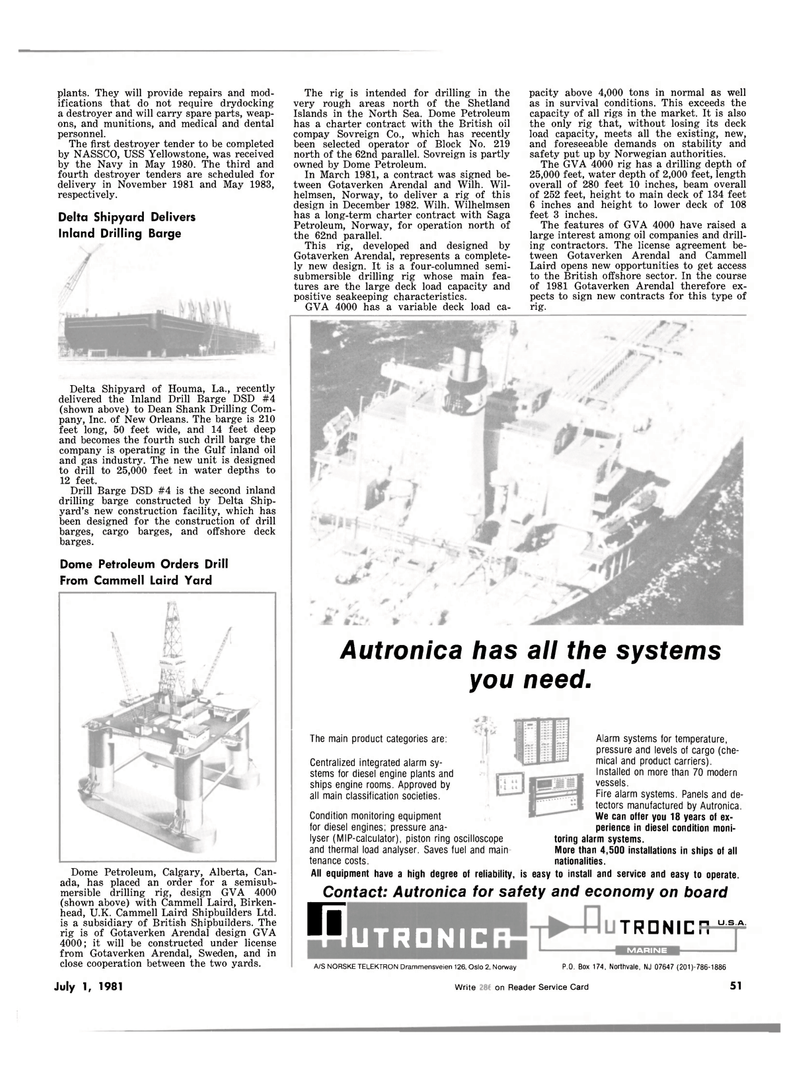

Dome Petroleum, Calgary, Alberta, Can- ada, has placed an order for a semisub- mersible drilling rig, design GVA 4000 (shown above) with Cammell Laird, Birken- head, U.K. Cammell Laird Shipbuilders Ltd. is a subsidiary of British Shipbuilders. The rig is of Gotaverken Arendal design GVA 4000; it will be constructed under license from Gotaverken Arendal, Sweden, and in close cooperation between the two yards.

July 1, 1981

The rig is intended for drilling in the very rough areas north of the Shetland

Islands in the North Sea. Dome Petroleum has a charter contract with the British oil compay Sovreign Co., which has recently been selected operator of Block No. 219 north of the 62nd parallel. Sovreign is partly owned by Dome Petroleum.

In March 1981, a contract was signed be- tween Gotaverken Arendal and Wilh. Wil- helmsen, Norway, to deliver a rig of this design in December 1982. Wilh. Wilhelmsen has a long-term charter contract with Saga

Petroleum, Norway, for operation north of the 62nd parallel.

This rig, developed and designed by

Gotaverken Arendal, represents a complete- ly new design. It is a four-columned semi- submersible drilling rig whose main fea- tures are the large deck load capacity and positive seakeeping characteristics.

GVA 4000 has a variable deck load ca- pacity above 4,000 tons in normal as well as in survival conditions. This exceeds the capacity of all rigs in the market. It is also the only rig that, without losing its deck load capacity, meets all the existing, new, and foreseeable demands on stability and safety put up by Norwegian authorities.

The GVA 4000 rig has a drilling depth of 25,000 feet, water depth of 2,000 feet, length overall of 280 feet 10 inches, beam overall of 252 feet, height to main deck of 134 feet 6 inches and height to lower deck of 108 feet 3 inches.

The features of GVA 4000 have raised a large interest among oil companies and drill- ing contractors. The license agreement be- tween Gotaverken Arendal and Cammell

Laird opens new opportunities to get access to the British offshore sector. In the course of 1981 Gotaverken Arendal therefore ex- pects to sign new contracts for this type of rig.

Autronica has all the systems you need.

The main product categories are:

Centralized integrated alarm sy- stems for diesel engine plants and ships engine rooms. Approved by all main classification societies.

Condition monitoring equipment for diesel engines; pressure ana- lyser (MlP-calculator), piston ring oscilloscope and thermal load analyser. Saves fuel and main tenance costs.

Alarm systems for temperature, pressure and levels of cargo (che- mical and product carriers).

Installed on more than 70 modern vessels.

Fire alarm systems. Panels and de- tectors manufactured by Autronica.

We can offer you 18 years of ex- perience in diesel condition moni- toring alarm systems.

More than 4,500 installations in ships of all nationalities.

All equipment have a high degree of reliability, is easy to install and service and easy to operate.

Contact: Autronica for safety and economy on board n UTRDNIC TRONIC* U.S.A.

MARINE

A/S NORSKE TELEKTRON Drammensveien 126, Oslo 2, Norway P.O. Box 174, Northvale, NJ 07647 (201 )-786-1886

Write 503 on Reader Service Card 51

48

48

3rd Cover

3rd Cover