Page 5: of Maritime Reporter Magazine (July 15, 1981)

Read this page in Pdf, Flash or Html5 edition of July 15, 1981 Maritime Reporter Magazine

Robert Ware Establishes

His Own Maritime Public

Relations Service

Robert Ware

Robert Ware, editor of MARI-

TIME REPORTER / Engineering

News, has announced the estab- lishment of his own firm, Robert

Ware Associates (RWA). Effec- tive with the completion of this issue, July 15, Mr. Ware will leave his position as editor of MR/EN to devote full time to his new career. Prior to joining MR/EN in April 1980, he had been editor of Marine Engineering/Log from 1962 to March 1980; his associ- ation with ME/L began in 1956.

RWA will provide public rela- tions services, including news re- leases, feature articles, product promotions, market research, and consulting to clients in the ma- rine industry worldwide and to companies seeking to enter the field.

Mr. Ware can be contacted at (212) 989-1485, or write to 10

Downing Street, New York, N.Y. 10014.

Circular Detailing New

Suez Canal Regulations

Available From Candia

Following the recent announce- ment by Suez Canal authorities that new beam and draft regula- tions have gone into effect for the 120-mile waterway, a circu- lar giving specifics is available from Candia Shipping (USA),

Inc. as a service to the U.S. ship- ping industry. "As a major spe- cialist in attending transits through the Canal for vessels of all flags, we have been awaiting this new step ever since Step One of the first stage of Canal im- provements was announced in

January 1981," said Ward Lape,

Candia's manager of U.S. oper- ations.

When Step One went into ef- fect early this year, the maxi- mum beam allowable was in- creased from 160.5 feet to 180.6 feet and then raised to 200 feet.

This allowed vessels to transit the Canal up to depths of 42 feet for the first time. Previously, ves- sels drawing over 38 feet were unable to use the waterway. Un- der the new regulations, Candia has learned that certain vessels will now be able to transit at a depth of 46 feet.

For a free copy of the circular,

Write 35 on Reader Service Card

IMODCO Receives Order

From Petrobras For $5-Million SPM Terminal

An order for a Single Point

Mooring terminal, valued at ap- proximately $5 million, has been awarded to IMODCO, a unit of

AMCA International Corporation, by Petrobras, the national oil company of Brazil.

To be sited in the Campos Ba- sin offshore Brazil in 338 feet of water, the terminal will perma- nently moor a 53,000-dwt stor- age/processing tanker in the Ba- dejo Field. The SPM will include an MPDU capable of transferring live crude from subsea wells to the dedicated tanker at 1,000-psi pressure. Processed crude will then be offloaded via shuttle tankers which will moor along- side.

Completion and installation is scheduled for autumn 1981.

A pioneer in the field, IMOD-

CO's offshore terminals date back to 1959 and are utilized by lead- ing oil companies, mining compa- nies and the military. This is

IMODCO's third SPM for use in

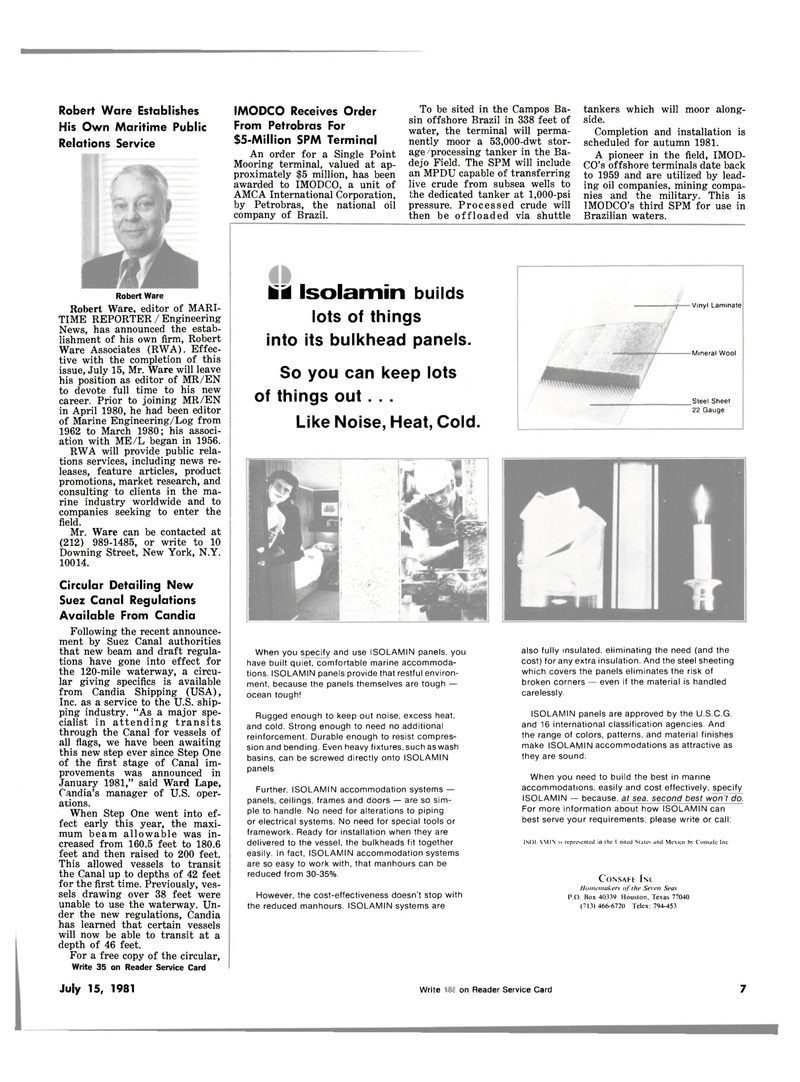

Brazilian waters. fci Isolamin builds lots of things into its bulkhead panels.

So you can keep lots of things out . . .

Like Noise, Heat, Cold. —f Vinyl Laminate -Mineral Wool _Steel Sheet 22 Gauge

When you specify and use ISOLAMIN panels, you have built quiet, comfortable marine accommoda- tions. ISOLAMIN panels provide that restful environ- ment, because the panels themselves are tough — ocean tough!

Rugged enough to keep out noise, excess heat, and cold. Strong enough to need no additional reinforcement. Durable enough to resist compres- sion and bending. Even heavy fixtures, such as wash basins, can be screwed directly onto ISOLAMIN panels

Further, ISOLAMIN accommodation systems — panels, ceilings, frames and doors — are so sim- ple to handle. No need for alterations to piping or electrical systems. No need for special tools or framework. Ready for installation when they are delivered to the vessel, the bulkheads fit together easily. In fact, ISOLAMIN accommodation systems are so easy to work with, that manhours can be reduced from 30-35%.

However, the cost-effectiveness doesn't stop with the reduced manhours. ISOLAMIN systems are also fully insulated, eliminating the need (and the cost) for any extra insulation. And the steel sheeting which covers the panels eliminates the risk of broken corners — even if the material is handled carelessly.

ISOLAMIN panels are approved by the U.S.C.G. and 16 international classification agencies. And the range of colors, patterns, and material finishes make ISOLAMIN accommodations as attractive as they are sound.

When you need to build the best in marine accommodations, easily and cost effectively, specify

ISOLAMIN — because, at sea. second best won't do.

For more information about how ISOLAMIN can best serve your requirements, please write or call:

ISOI \\1I\ Is rcpresenled in the I nited Suites and Mexico by Consufe Inc

CONSAFE INC

Homemakers of the Seven Seas

P.O. Box 40339 Houston. Texas 77040 (713) 466-672(1 Telex: 794-453

July 15, 1981 Write 161 on Reader Service Card 7

4

4

6

6