Page 7: of Maritime Reporter Magazine (July 15, 1981)

Read this page in Pdf, Flash or Html5 edition of July 15, 1981 Maritime Reporter Magazine

Bath Awarded $9-Million

Navy Contract For Post

Shakedown Work On FFGs

Bath Iron Works, Bath, Maine, is being awarded a $9,070,000 cost type order for post shakedown availability work on FFG-7 class guided missile frigates FFG-21, 24, 26, 29, 32, 33, and 34. The

Naval Sea Systems Command is the contracting activity. (N00024- 80-G-2146)

Puget Sound Tug & Barge

Will Build 12 Barges

Costing $39.5 Million

Puget Sound Tug & Barge Co., a subsidiary of Crowley Maritime

Corporation, One Market Plaza,

San Francisco, has applied for

Title XI guarantees to aid in fi- nancing t he construction of 12 barges.

The vessels will be of three types: four 240-foot-long lighter- age barges, four 282-foot oil/ grain barges, and four 400-foot oil/deck cargo barges. Zidell Inc.,

Portland, Ore., has been selected to build two of the lighterage barges. F.M.C. Corporation, also of Portland, is scheduled to build the remaining lighterage barges.

No builders have been named for the other barges, and no delivery dates have been set for any of the vessels.

When completed the barges are expected to be operated on the

U.S. West Coast.

If approved, the Title XI guar- antee would cover $34.5 million, roughly 87y2 percent of the ves- sels' $39.5-million combined esti- mated actual cost.

Seaco Energy/Coastal

Carriers Joint Venture

Plans Floating Terminals

Sea Containers, Inc. announced recently that its wholly owned subsidiary, Seaco Energy Corpo- ration, and Coastal Carriers Cor- poration have formed a partner- ship to build and operate Ameri- can-flag floating terminals. These terminals, located in New Orleans at the mouth of the Mississippi, will be used to load coal for ex- port to Europe and the Far East.

The terminals will take aboard coal from river barges or shore- side coal-handling stations, then move to deep water and load the coal on oceangoing vessels for transport. Two trips, a total of 12 hours loading time, will com- plete the loading of the ocean- going vessel to some 150,000 tons capacity. The terminals will have a capacity of 12,000,000 tons per year. At the present time the draft limitation in the river is 40 feet, allowing vessels of only 70,000 dwt to load and safely sail

July 15, 1981 across a shallow sand bar. The concept is to load the coal on the oceangoing vessel at two points: the first in the Mississippi River and the second in the Gulf of

Mexico, where there is a 65-foot draft.

The first terminal, at a cost of approximately $45 million, is to be constructed in an American shipyard and should be operation- al in 1983. This terminal will have an overall length of 608 feet, beam of 122 feet, and draft of 28 feet.

It is planned to contract with coal shippers or importers on a consecutive voyage basis and load 100,000-150,000-dwt vessels for discharge in Europe and the Far

East. This project will enable the buyers to obtain freight rates at a discount from the current mar- ket. Lower delivery costs of

American coal will eliminate some of the disadvantages of American coal sales, resulting in lower de- livered costs, and reduce demur- rage charges being paid at East- ern U.S. ports.

The partners, experienced transportation companies, special- ize in container, tanker, and bulk carrier trades. The sales agent for the terminal will be Coal Export

Logistics Corporation.

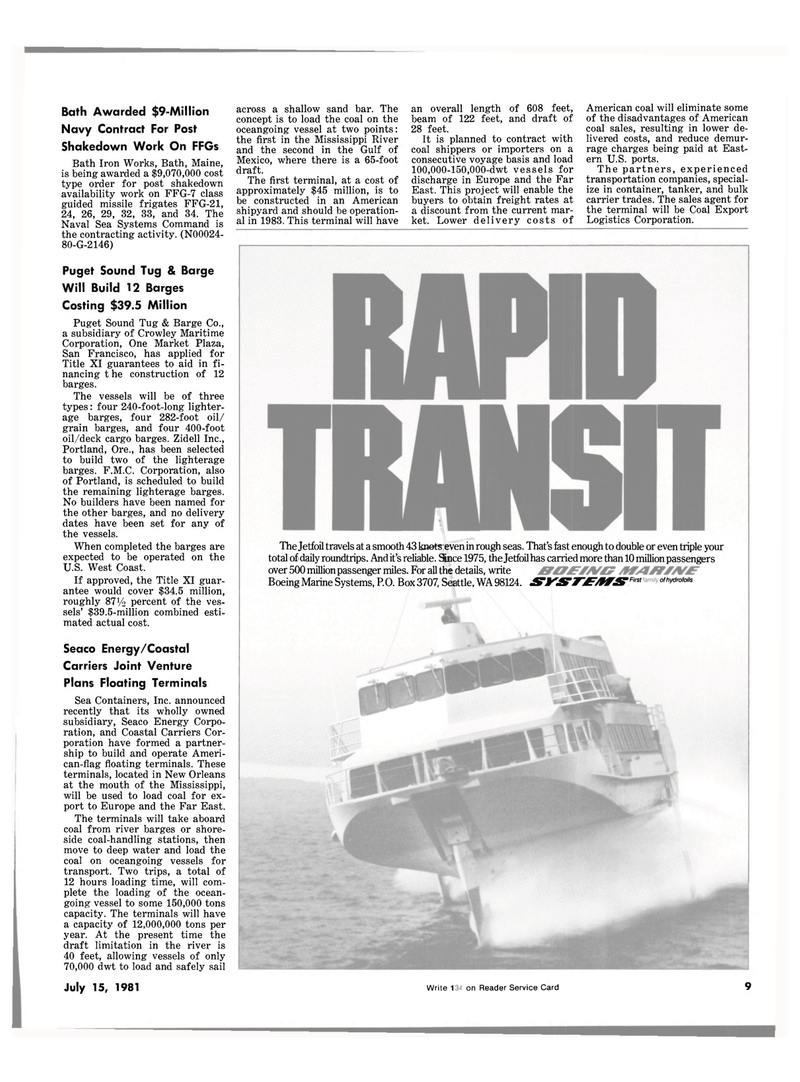

The Jetfoil travels at a smooth 43 knots even in rough seas. That's fast enough to double or even triple your total of daily roundtrips. And it's reliable. Snce 1975, the Jetfoil has carried more than 10 million passengers over 500 million passenger miles. For all the details, write

Boeing Marine Systems, P.O. Box 3707, Seattle, WA 98124. J&*rSW~£r/§WS'Firs Write 161 on Reader Service Card 9

6

6

8

8