Page 31: of Maritime Reporter Magazine (September 1981)

Read this page in Pdf, Flash or Html5 edition of September 1981 Maritime Reporter Magazine

heavy industry requires its port to be a heavy-lift facility. The

P&H 5300-R, operating nominally with a 100-foot boom, has the ability to lift 400,000 pounds at a 25-foot radius, 149,000 out to 50 feet, and more than 58,000 pounds at a 100-foot outreach.

When needed, the boom can be shortened to 70 feet and lift ca- pacity will increase to 600,000 pounds at an 18-foot radius.

Harnischfeger designed and built special attachments to meet the Port of Milwaukee's partic- ular needs. The boom foot mount- ing was raised to a height of 17 feet above the dock to enable the crane to work closer to the ship and increasing the boom reach over the deck of the ship. The extra-heavy-duty mast will fold forward to a height of 26 feet, enabling the crane to travel through a 27-foot underpass in the Port area. For the same rea- son, the height of the operator's cab was held to 26 feet. The op- erator's eye level is at 23 feet above the dock, which will give him a good view into the holds of most freighters sailing the

Great Lakes.

For further information and free literature on all P&H cranes,

Write 33 on Reader Service Card

HERCULES

Shipping firms with self-un- loading vessels are benefiting from the use of an ultra-high molecular weight (UHMW) poly- mer manufactured by Hercules

Incorporated to line their cargo hold hoppers. Ship operators that are saving thousands of dollars per unloading hour include many well-known names in Great Lakes shipping, such as American

Steamship, Hanna Mining, Huron

Cement, Canada Steamship Lines,

Algoma Central Railway's Marine

Division, Upper Lakes Shipping,

Hall Corporation Shipping, and

St. Lawrence Cement Company.

In addition, shipbuilding itself is undergoing a revolution in self- unloading hopper designs thanks to the properties of UHMW poly- mer with molecular weights in the range of three to six million.

It has a coefficient of friction ap- proximately half that of steel, providing a non-stick surface that, these shippers point out, greatly facilitates the unloading of cargo even when it is wet or sticky.

This means that materials such as coal, gypsum, and cement flow more easily and reliably than on unlined metal surfaces. It also permits wet material to slide more easily on the plastic's wax- like surfaces. This, in turn, has given them two options: to design steep hopper slopes, or to install liner sheets of 1900 UHMW poly- mer and reduce hopper slopes.

Normally designed with slopes as high as 57 degrees, hoppers of self-unloading ships can now be angled as low as 37 degrees when the polymer liner is used.

The advantages of this reduced slope angle have been proven out along several lines, according to

Mentor Dynamics, Limited, On- tario-based fabricator pioneering in this new method of lining hop- pers.

Shippers attest to the fact that the lower angle design on the hoppers of their freighters has resulted in several benefits: it in- creases the weight (or amount) of material that can be carried; and it improves the stability of the ship by making it possible to store this great volume below the vessel's center of gravity.

Some shippers report that their (continued on page 34)

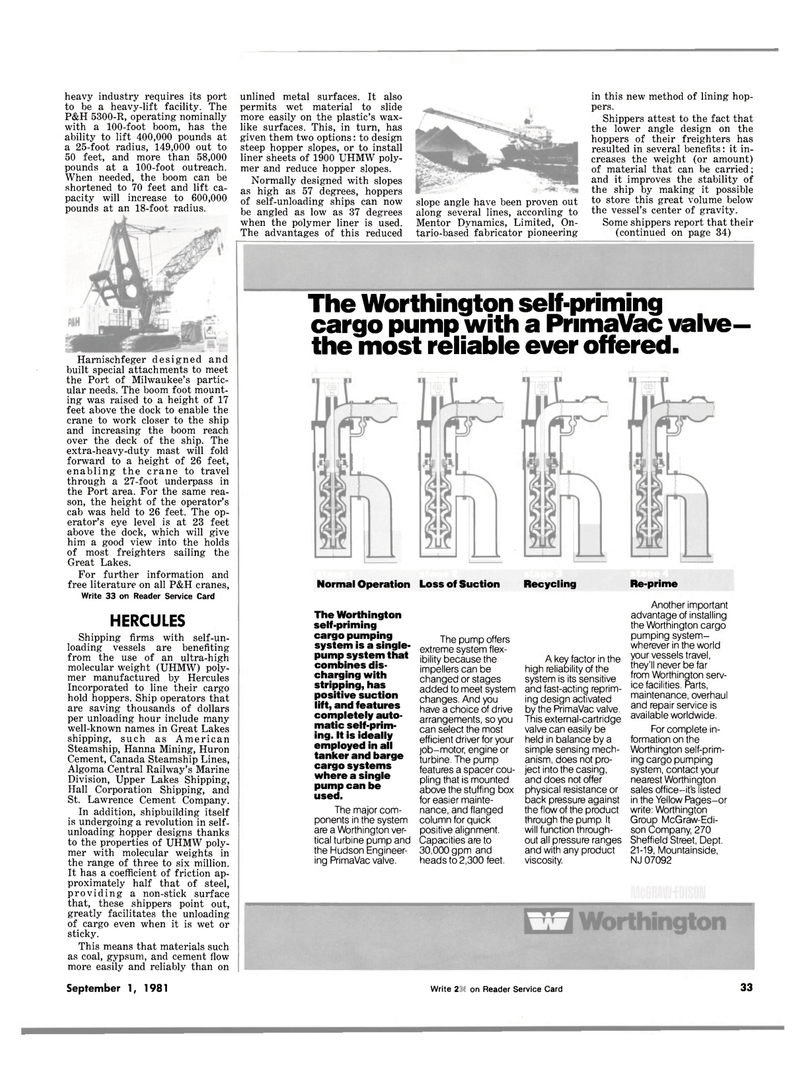

The Worthington self-priming cargo pump with a PrimaVac valve— the most reliable ever offered.

Normal Operation

The Worthington self-priming cargo pumping system is a single- pump system that combines dis- charging with stripping, has positive suction lift, and features completely auto- matic self-prim- ing. It is ideally employed in all tanker and barge cargo systems where a single pump can be used.

The major com- ponents in the system are a Worthington ver- tical turbine pump and the Hudson Engineer- ing PrimaVac valve.

Loss of Suction

The pump offers extreme system flex- ibility because the impellers can be changed or stages added to meet system changes. And you have a choice of drive arrangements, so you can select the most efficient driver for your job-motor, engine or turbine. The pump features a spacer cou- pling that is mounted above the stuffing box for easier mainte- nance, and flanged column for quick positive alignment.

Capacities are to 30,000 gpm and heads to 2,300 feet.

Recycling

A key factor in the high reliability of the system is its sensitive and fast-acting reprim- ing design activated by the PrimaVac valve.

This external-cartridge valve can easily be held in balance by a simple sensing mech- anism, does not pro- ject into the casing, and does not offer physical resistance or back pressure against the flow of the product through the pump. It will function through- out all pressure ranges and with any product viscosity.

Re-prime

Another important advantage of installing the Worthington cargo pumping system- wherever in the world your vessels travel, they'll never be far from Worthington serv- ice facilities. Parts, maintenance, overhaul and repair service is available worldwide.

For complete in- formation on the

Worthington self-prim- ing cargo pumping system, contact your nearest Worthington sales office-it's listed in the Yellow Pages-or write: Worthington

Group McGraw-Edi- son Company, 270

Sheffield Street, Dept. 21-19, Mountainside,

NJ 07092

September 1, 1981 Write 200 on Reader Service Card 33 1

30

30

32

32