Page 19: of Maritime Reporter Magazine (April 1982)

Read this page in Pdf, Flash or Html5 edition of April 1982 Maritime Reporter Magazine

started by discussing the effects of the 1973 energy crisis on ma- rine propulsion systems, and the efforts made by engine manufac- turers toward contributing to an increased economy in ship oper- ations. Waste-heat recovery sys- tems were then discussed in de- tail, including recovery of waste heat of the charge air coolers, and recovery of engine cooling water heat. The possible savings resulting from the use of these systems were then examined.

Alternatives and future solu- tions for economic sources for power were finally discussed.

The meeting was attended by over ninety members, student members and guests.

Nichols Joins DEBEG's

Marine Sales Management

David B. Nichols

David B. Nichols has been named assistant to the U.S. sales manager for DEBEG Marine Inc.,

Salem, N.H., according to sales manager Robert McCarthy.

DEBEG is a subsidiary of

DEBEG GmbH, the marine com- munications and navigation equipment company headquar- tered in Hamburg, Germany. Mr.

Nichols's background includes po- sitions with the Texaco U.S. fleet and the Inter-Lake Steamship

Co.

Camcraft Names Selco As

Exclusive Far East Agent

Camcraft, Inc., of Marrero, La., builder of aluminum crewboats and patrol boats, has selected

Selco (Shipyard) Pte. Ltd. as its exclusive agent for the area con- sisting of Singapore, Malaysia,

Brunei, Thailand, Indonesia, Phil- ippines, and Hong Kong. Selco will build the full range of ves- sels using the complete Camcraft design package under the super- vision of Camcraft personnel.

St. Louis Ship Opens

New Propeller Shop

St. Louis Ship recently opened its new Propeller Shop as part of the shipyard's expanding ma- rine services.

The Propeller Shop is built on a site in the northwest portion of the shipyard, near the foot of

Marceau Street, on the Missis- sippi River in South St. Louis.

The location is adjacent to con- solidated propeller, shaft and rud- der storage areas. The approxi- mately 8,400-square-foot facility is serviced by two overhead cranes and is outfitted with the latest in repair, welding, and machining equipment.

According to a spokesman for

St. Louis Ship, the construction of the consolidated Propeller

Shop facility enables the firm to provide "full service" including propeller straightening, build-up, machining and repair work, and rudder manufacture and repair. © Copyright 1981 BUTTERWORTH Inc.

The preengineered building houses a prototype hydraulic pro- peller straightening press capable of straightening propellers up to 12 feet in diameter, six propeller work stations, 2,500 square feet of rudder repair area, a shaft machining lathe capable of ma- chining shafts of 16-inch diame- ter, 40 feet long, and weighing as much as 12 tons, and a shaft welding fixture capable of weld- ing operations on 16-inch-diam- eter by 40-foot-long shafts em- ploying the latest technological advances in strip welding.

St. Louis Ship is one of three major inland shipyards operated by Pott Industries, Inc., a sub- sidiary of Houston Natural Gas

Corporation.

For complete details on St.

Louis Ship's new Propeller Shop,

Write 34 on Reader Service Card

Oil/water separation made simple.

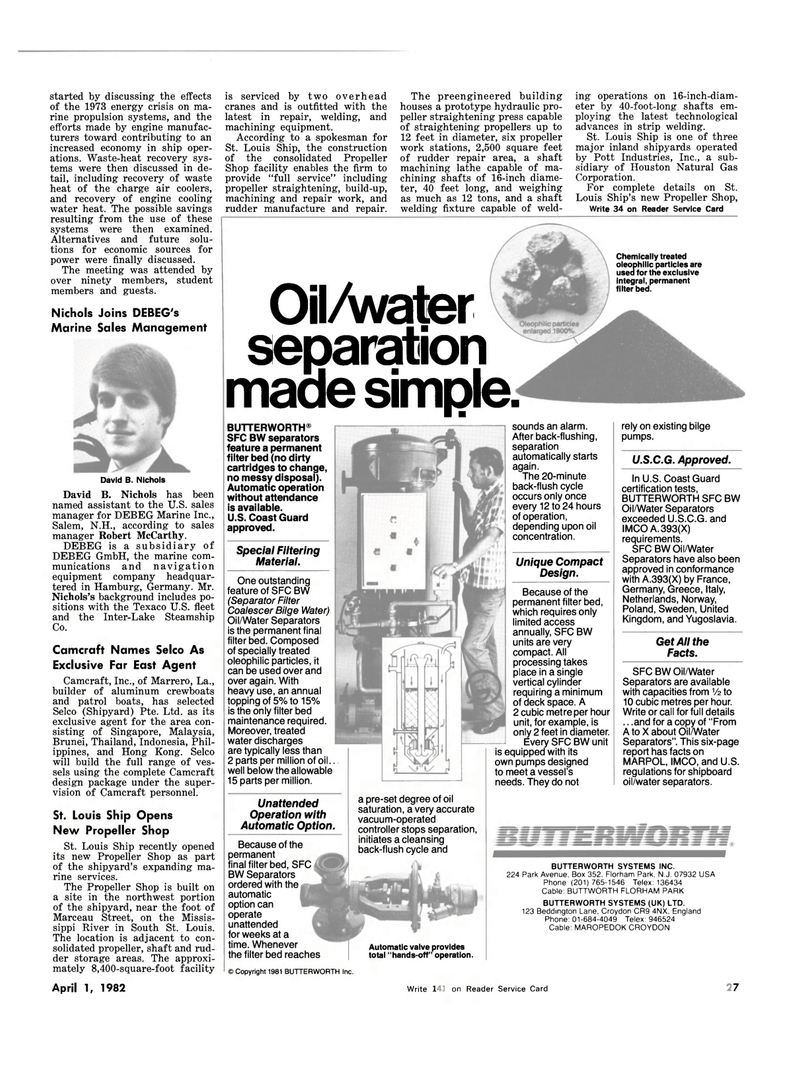

Chemically treated oleophilic particles are used for the exclusive integral, permanent filter bed.

BUTTERWORTH®

SFC BW separators feature a permanent filter bed (no dirty cartridges to change, no messy disposal).

Automatic operation without attendance is available.

U.S. Coast Guard approved.

Special Filtering

Material.

One outstanding feature of SFC BW (Separator Filter

Coalescer Bilge Water)

Oil/Water Separators is the permanent final filter bed. Composed of specially treated oleophilic particles, it can be used over and over again. With heavy use, an annual topping of 5% to 15% is the only filter bed maintenance required.

Moreover, treated water discharges are typically less than 2 parts per million of oil., well below the allowable 15 parts per million.

Unattended

Operation with

Automatic Option.

Because of the permanent final filter bed, SFC

BW Separators ordered with the automatic option can operate unattended for weeks at a time. Whenever the filter bed reaches a pre-set degree of oil saturation, a very accurate vacuum-operated controller stops separation, initiates a cleansing back-flush cycle and

Automatic valve provides total "hands-off" operation. sounds an alarm.

After back-flushing, separation automatically starts again.

The 20-minute back-flush cycle occurs only once every 12 to 24 hours of operation, depending upon oil concentration.

Unique Compact

Design.

Because of the permanent filter bed, which requires only limited access annually, SFC BW units are very compact. All processing takes place in a single vertical cylinder requiring a minimum of deck space. A 2 cubic metre per hour unit, for example, is only 2 feet in diameter.

Every SFC BW unit is equipped with its own pumps designed to meet a vessel's needs. They do not rely on existing bilge pumps.

U.S.C.G. Approved.

In U.S. Coast Guard certification tests,

BUTTERWORTH SFC BW

Oil/Water Separators exceeded U.S.C.G. and

IMCO A.393(X) requirements.

SFC BW Oil/Water

Separators have also been approved in conformance with A.393(X) by France,

Germany, Greece, Italy,

Netherlands, Norway,

Poland, Sweden, United

Kingdom, and Yugoslavia.

Get All the

Facts.

SFC BW Oil/Water

Separators are available with capacities from V2 to 10 cubic metres per hour.

Write or call for full details .. .and for a copy of "From

A to X about Oil/Water

Separators". This six-page report has facts on

MARPOL, IMCO, and U.S. regulations for shipboard oil/water separators.

BUTTERWORTH SYSTEMS INC. 224 Park Avenue. Box 352. Florham Park. N.J. 07932 USA

Phone' (201) 765-1546 Telex: 136434

Cable: BUTTWORTH FLORHAM PARK

BUTTERWORTH SYSTEMS (UK) LTD. 123 Beddington Larie, Croydon CR9 4NX. England

Phone: 01-684-4049 Telex: 946524

Cable: MAROPEDOK CROYDON

April 1, 1982 Write 100 on Reader Service Card 107

18

18

20

20