Page 14: of Maritime Reporter Magazine (July 15, 1983)

Read this page in Pdf, Flash or Html5 edition of July 15, 1983 Maritime Reporter Magazine

Diesel Power Review (continued from page 17)

ELECTRO-MOTIVE

DIVISION—GM

Write 49 on Reader Service Card

A new, more fuel-efficient series 645 engine was introduced by

Electro-Motive Division of Gen- eral Motors this year. This new engine provides a 3 percent reduc- tion in fuel consumption over pre- vious models. "This new model," said T. J.

Lehman, EMD marine and indus- trial sales manager, "represents the latest step in our continuing efforts to provide our customers with the most fuel-efficient diesel, while maintaining our levels of re- liability, interchangeability, and maintainability. We are very ex- cited about this more fuel-efficient model. Further, we expect even more improvements in fuel effi- ciency in the future."

The new EC engine series com- bines innovative design features that ensure superior field perform- ance, extended operating service, and enable the engine to with- stand higher operating pressures with state-of-the-art turbocharger technology. The 645EC uses a 16:1 compression ratio piston. The in- creased compression ratio from 14.5:1 produces the same power output with less fuel. A newly de- signed impeller and compressor has been incorporated into the turbocharger.

EMD has also introduced, this year, a heavier crankcase option, the 645F engine. This engine, de- signed for high horsepower levels, is currently available in 16 and 20-cylinder models.

Later this year, results should be in on the next phase of EMD's blended fuels field testing pro- gram. The division will report on the findings.

A new multimillion-dollar blended fuels engine test facility is under construction at EMD. This is in addition to the 13 perform- ance and durability test facilities

EMD already has.

In addition to this investment,

EMD has expanded its computer- ized design and manufacturing ca- pabilities into an integrated sys- tem (CAD/CAM) which enables engineering designs to be commu- nicated directly to the shop floor.

The result is improved quality.

Computer Aided Design/Computer

Aided Manufacturing puts the fac- tory of the future into EMD's op- erations today.

GENERAL ELECTRIC DIESEL

Write 50 on Reader Service Card

Rating increases of approxi- mately 10 percent, resulting from a series of significant technologi- cal advances, have been an- nounced by General Electric Die- sel Power Products, Erie, Pa., for its line of diesel engines and power modules.

The recent advances have been completely laboratory and field tested and include a higher strength piston, modified exhaust valves and seats, 18-mm double helix fuel pump, enlarged parallel low-pressure fuel system, groove- less bearings, and turbocharger improvements.

As a result of the newly devel- oped advances, General Electric is offering the following ratings: 900 RPM 1050 RPM

Marine Propulsion 7FDM16 3400 4000 7FMD12 2550 3000 7FDM8 1800 1525

Power Modules (marine & stationary) 16-cylinder 2,400 kW 12-cylinder 1,800 kW

Power Modules (oil well drilling) 16-cylinder 2650 kw 12-cylinder 2000 kw

In addition to product improve- ments, General Electric is offering its customers complete service and parts support and training capa- bilities.

For example, the new GE Ac- tionline gets the parts required to repair an engine breakdown to the customer within 48 hours or less.

And with the Actionline, parts for normal delivery are shipped by the end of the second working day.

General Electric's new multi- million-dollar Learning and Com- munications Center at its Erie, (continued on page 20)

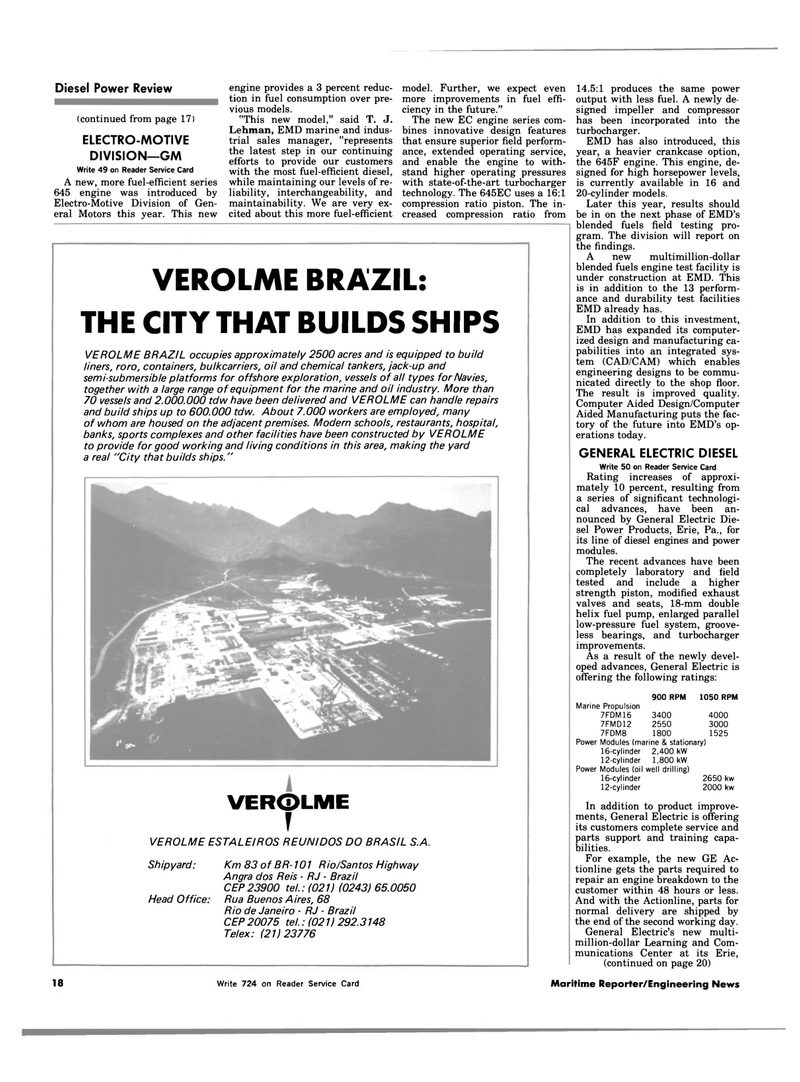

VEROLME BRAZIL:

THE CITY THAT BUILDS SHIPS

VEROLME BRAZIL occupies approximately 2500 acres and is equipped to build liners, roro, containers, bulkcarriers, oil and chemical tankers, jack-up and semi-submersible platforms for offshore exploration, vessels of all types for Navies, together with a large range of equipment for the marine and oil industry. More than 70 vessels and 2.000.000 tdw have been delivered and VEROLME can handle repairs and build ships up to 600.000 tdw. About 7.000 workers are employed, many of whom are housed on the adjacent premises. Modern schools, restaurants, hospital, banks, sports complexes and other facilities have been constructed by VEROLME to provide for good working and living conditions in this area, making the yard a real "City that builds ships." i VEROLME }

VEROLME ESTALEIROS REUNIDOS DO BRASIL S.A.

Shipyard: Km 83 of BR-101 Rio/Santos Highway

Angra dos Re is - RJ - Brazil

CEP 23900 tel.: (021) (0243) 65.0050

Head Office: Rua Buenos Aires, 68

Rio de Janeiro - RJ - Brazil

CEP 20075 tel.: (021) 292.3148

Telex: (21)23776 18 Write 724 on Reader Service Card Maritime Reporter/Engineering News

13

13

15

15