Page 6: of Maritime Reporter Magazine (November 15, 1983)

Read this page in Pdf, Flash or Html5 edition of November 15, 1983 Maritime Reporter Magazine

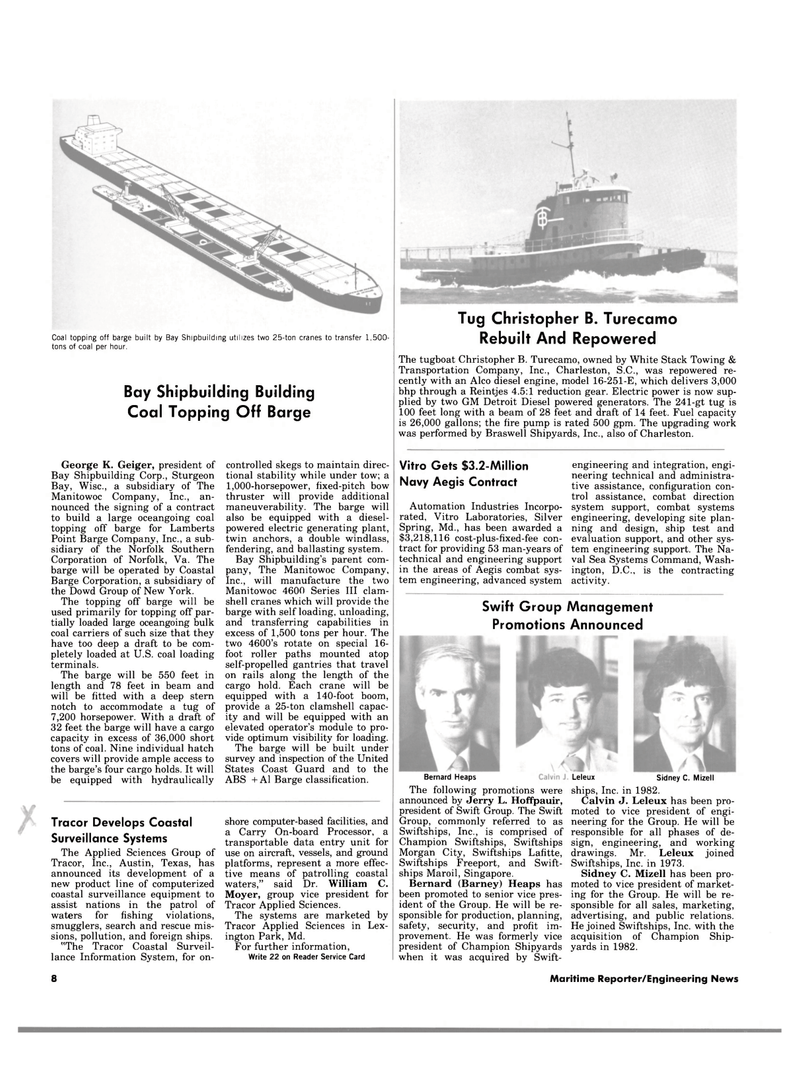

Coal topping off barge built by Bay Shipbuilding utilizes two 25-ton cranes to transfer 1,500- tons of coal per hour.

Bay Shipbuilding Building

Coal Topping Off Barge

George K. Geiger, president of

Bay Shipbuilding Corp., Sturgeon

Bay, Wise., a subsidiary of The

Manitowoc Company, Inc., an- nounced the signing of a contract to build a large oceangoing coal topping off barge for Lamberts

Point Barge Company, Inc., a sub- sidiary of the Norfolk Southern

Corporation of Norfolk, Va. The barge will be operated by Coastal

Barge Corporation, a subsidiary of the Dowd Group of New York.

The topping off barge will be used primarily for topping off par- tially loaded large oceangoing bulk coal carriers of such size that they have too deep a draft to be com- pletely loaded at U.S. coal loading terminals.

The barge will be 550 feet in length and 78 feet in beam and will be fitted with a deep stern notch to accommodate a tug of 7,200 horsepower. With a draft of 32 feet the barge will have a cargo capacity in excess of 36,000 short tons of coal. Nine individual hatch covers will provide ample access to the barge's four cargo holds. It will be equipped with hydraulically controlled skegs to maintain direc- tional stability while under tow; a 1,000-horsepower, fixed-pitch bow thruster will provide additional maneuverability. The barge will also be equipped with a diesel- powered electric generating plant, twin anchors, a double windlass, fendering, and ballasting system.

Bay Shipbuilding's parent com- pany, The Manitowoc Company,

Inc., will manufacture the two

Manitowoc 4600 Series III clam- shell cranes which will provide the barge with self loading, unloading, and transferring capabilities in excess of 1,500 tons per hour. The two 4600's rotate on special 16- foot roller paths mounted atop self-propelled gantries that travel on rails along the length of the cargo hold. Each crane will be equipped with a 140-foot boom, provide a 25-ton clamshell capac- ity and will be equipped with an elevated operator's module to pro- vide optimum visibility for loading.

The barge will be built under survey and inspection of the United

States Coast Guard and to the

ABS +A1 Barge classification.

Tracor Develops Coastal

Surveillance Systems

The Applied Sciences Group of

Tracor, Inc., Austin, Texas, has announced its development of a new product line of computerized coastal surveillance equipment to assist nations in the patrol of waters for fishing violations, smugglers, search and rescue mis- sions, pollution, and foreign ships. "The Tracor Coastal Surveil- lance Information System, for on- shore computer-based facilities, and a Carry On-board Processor, a transportable data entry unit for use on aircraft, vessels, and ground platforms, represent a more effec- tive means of patrolling coastal waters," said Dr. William C.

Moyer, group vice president for

Tracor Applied Sciences.

The systems are marketed by

Tracor Applied Sciences in Lex- ington Park, Md.

For further information,

Write 22 on Reader Service Card

Tug Christopher B. Turecamo

Rebuilt And Repowered

The tugboat Christopher B. Turecamo, owned by White Stack Towing &

Transportation Company, Inc., Charleston, S.C., was repowered re- cently with an Alco diesel engine, model 16-251-E, which delivers 3,000 bhp through a Reintjes 4.5:1 reduction gear. Electric power is now sup- plied by two GM Detroit Diesel powered generators. The 241-gt tug is 100 feet long with a beam of 28 feet and draft of 14 feet. Fuel capacity is 26,000 gallons; the fire pump is rated 500 gpm. The upgrading work was performed by Braswell Shipyards, Inc., also of Charleston.

Vitro Gets $3.2-Million

Navy Aegis Contract

Automation Industries Incorpo- rated, Vitro Laboratories, Silver

Spring, Md., has been awarded a $3,218,116 cost-plus-fixed-fee con- tract for providing 53 man-years of technical and engineering support in the areas of Aegis combat sys- tem engineering, advanced system engineering and integration, engi- neering technical and administra- tive assistance, configuration con- trol assistance, combat direction system support, combat systems engineering, developing site plan- ning and design, ship test and evaluation support, and other sys- tem engineering support. The Na- val Sea Systems Command, Wash- ington, D.C., is the contracting activity.

Swift Group Management

Promotions Announced

Bernard Heaps

The following promotions were announced by Jerry L. Hoffpauir, president of Swift Group. The Swift

Group, commonly referred to as

Swiftships, Inc., is comprised of

Champion Swiftships, Swiftships

Morgan City, Swiftships Lafitte,

Swiftships Freeport, and Swift- ships Maroil, Singapore.

Bernard (Barney) Heaps has been promoted to senior vice pres- ident of the Group. He will be re- sponsible for production, planning, safety, security, and profit im- provement. He was formerly vice president of Champion Shipyards when it was acquired by Swift-

Leleux Sidney C. Mizell ships, Inc. in 1982.

Calvin J. Leleux has been pro- moted to vice president of engi- neering for the Group. He will be responsible for all phases of de- sign, engineering, and working drawings. Mr. Leleux joined

Swiftships, Inc. in 1973.

Sidney C. Mizell has been pro- moted to vice president of market- ing for the Group. He will be re- sponsible for all sales, marketing, advertising, and public relations.

He joined Swiftships, Inc. with the acquisition of Champion Ship- yards in 1982. 8 Maritime Reporter/Engineering News

5

5

7

7