Page 44: of Maritime Reporter Magazine (August 1984)

Read this page in Pdf, Flash or Html5 edition of August 1984 Maritime Reporter Magazine

Volvo Penta (continued from page 45) 387 at 1,900 rpm and 367 bhp at 1,800 rpm. The engine uses 159 grams of fuel per bhp hour at the continuous rating.

Booth No. 604 Circle 88 on RSC

WATERCOM

Watercom—Waterway Commu- nications Systems, Inc.—is a fully automatic telephone system in- cluding management information services for traffic on the Missis- sippi, Ohio, and Illinois Rivers and many of their major tributaries, and on the Gulf Intracoastal

Waterway.

It is a private radiotelephone service that provides fast, reliable, direct two-way communications between company and vessel, ves- sel and shore, and vessel-to-vessel.

Booth No. 413 Circle 37 on RSC

WAUKESHA ENGINE

Waukesha Engine Division of

Dresser Industries will feature displays and information of its new AT25 high-output, medium- speed diesel series. Capable of op- erating on economical heavy fuel, these 250-mm bore engines in V- 12 and V-16 models and in-line 6- and 8-cylinder configurations fea- ture rugged, compact construction, good access to components for ease of service, low fuel consumption, and maximum interchangeability of parts between models for easier maintenance and smaller parts inventories.

Available for ship's propulsion and electrical service, the AT25 line is rated from 1,800 to 4,800 bhp at 1,000 rpm on distillate fuel, 1,620 to 4,320 bhp at 1,000 rpm on heavy fuel, and up to 3,360 kw electric.

Also included in Waukesha's display will be information on the

Waukesha/Scania line of efficient, dependable marine diesels. This line is made up of four in-line 6- cylinder versions and two V-8 models, two of which are available in turbocharged/intercooled config- urations.

Booth No. 113 Circle 38 on RSC

WARTSILA

Wartsila Diesel of Finland, one of the world's leading manufactur- ers of medium-speed diesel en- gines, will feature its "real" heavy fuel engine types Vasa 32 and

Vasa 22HF.

The Vasa 32, the largest of the

Wartsila heavy fuel engines, is one of the most popular medium- speed propulsion and auxiliary diesels. It is manufactured in seven different cylinder versions—four

V-form and three in-line designs— covering the output range from 2,010 to 9,180 bhp at 720-800 rpm.

The Vasa 22HF is the smallest heavy fuel engine on the market.

Its output range is 720-3,480 bhp at 900-1,200 rpm, provided by two

V-form and three in-line cylinder versions. Long-term service expe- rience with the Wartsila heavy fuel engines has confirmed that they are capable of burning the lowest fuel qualities of the future.

Today the entire Wartsila heavy fuel engine range is released for 7000 sec. Redwood 1 at 100 F.

Booth No. 403 Circle 39 on RSC

S.S. WHITE

S.S. White Industrial"' Products will feature its heavy-duty, flexi- ble reach rods, which provide for remote valve control in hard-to- reach, inaccessible, hazardous, or unsafe areas. Installation is quick and easy, even though the route to follow may be extremely complex, with multiple bends.

The U.S. Coast Guard has ac- cepted flexible reach rods for use in ballast, oil, and fuel tanks. In addition, the American Bureau of

Shipping has found reach rods suitable for use in all piping sys- tems and tanks on vessels classed by the Bureau. Lloyd's Register of

Shipping has also approved the use of S.S. White flexible reach rods for controlling forepeak suc- tion valves on all vessels under its classification.

Booth No. 402 Circle 40 on RSC

Worthington

Worthington's redesigned line of general-purpose end-suction pumps, with capacities to 1,500 gpm, is covered in a new brochure.

The cast-iron pumps, designated as the D-800 line, are available in 19 sizes, frame-mounted of close- coupled. The pumps are designed for minimum operating and main- tenance costs.

The D-800 has applications in all industries, including process, power generation, and HVAC sys- tems. Liquids pump include water, solvents, light oils, noncorrosive chemicals, coolants, and brine. The pumps will deliver liquid to heads of 400 feet (100 meters).

Booth No. 110 Circle 89 on RSC

CDI Marine Awarded $1.5-Million Navy Order

CDI Marine Company, head- quartered in Jacksonville, Fla. was recently awarded a $1,503,273 two- year contract from the Navy to furnish engineering and technical services in support of main and auxiliary gas, turbine, diesel and power transmission and ancillary equipment. The project will be managed at CDI Marine Com- pany's Philadelphia area facility located in Voorhees, N.J.

Literature Available On

New Mechanical Pump

Seals From Drew

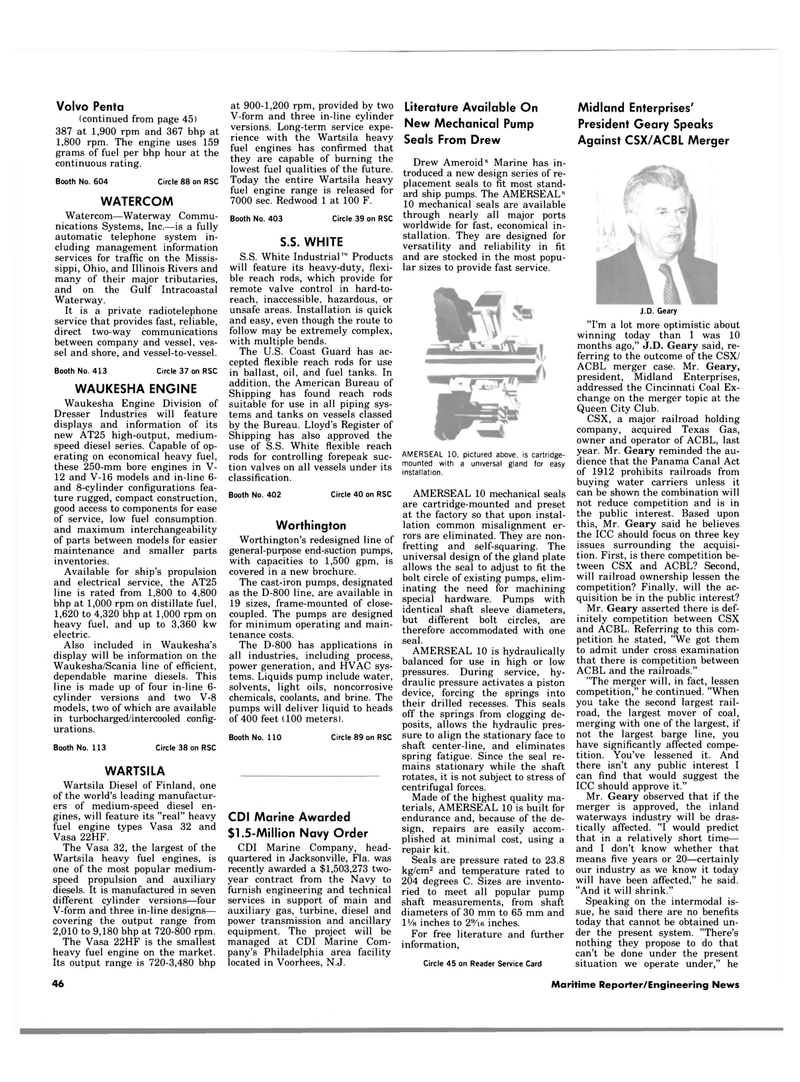

Drew Ameroid" Marine has in- troduced a new design series of re- placement seals to fit most stand- ard ship pumps. The AMERSEAL" 10 mechanical seals are available through nearly all major ports worldwide for fast, economical in- stallation. They are designed for versatility and reliability in fit and are stocked in the most popu- lar sizes to provide fast service.

AMERSEAL 10, pictured above, is cartridge- mounted with a universal gland for easy installation.

AMERSEAL 10 mechanical seals are cartridge-mounted and preset at the factory so that upon instal- lation common misalignment er- rors are eliminated. They are non- fretting and self-squaring. The universal design of the gland plate allows the seal to adjust to fit the bolt circle of existing pumps, elim- inating the need for machining special hardware. Pumps with identical shaft sleeve diameters, but different bolt circles, are therefore accommodated with one seal.

AMERSEAL 10 is hydraulically balanced for use in high or low pressures. During service, hy- draulic pressure activates a piston device, forcing the springs into their drilled recesses. This seals off the springs from clogging de- posits, allows the hydraulic pres- sure to align the stationary face to shaft center-line, and eliminates spring fatigue. Since the seal re- mains stationary while the shaft rotates, it is not subject to stress of centrifugal forces.

Made of the highest quality ma- terials, AMERSEAL 10 is built for endurance and, because of the de- sign, repairs are easily accom- plished at minimal cost, using a repair kit.

Seals are pressure rated to 23.8 kg/cm2 and temperature rated to 204 degrees C. Sizes are invento- ried to meet all popular pump shaft measurements, from shaft diameters of 30 mm to 65 mm and lVa inches to 29/i6 inches.

For free literature and further information,

Circle 45 on Reader Service Card

Midland Enterprises'

President Geary Speaks

Against CSX/ACBL Merger

J.D. Geary "I'm a lot more optimistic about winning today than I was 10 months ago," J.D. Geary said, re- ferring to the outcome of the CSX/

ACBL merger case. Mr. Geary, president, Midland Enterprises, addressed the Cincinnati Coal Ex- change on the merger topic at the

Queen City Club.

CSX, a major railroad holding company, acquired Texas Gas, owner and operator of ACBL, last year. Mr. Geary reminded the au- dience that the Panama Canal Act of 1912 prohibits railroads from buying water carriers unless it can be shown the combination will not reduce competition and is in the public interest. Based upon this, Mr. Geary said he believes the ICC should focus on three key issues surrounding the acquisi- tion. First, is there competition be- tween CSX and ACBL? Second, will railroad ownership lessen the competition? Finally, will the ac- quisition be in the public interest?

Mr. Geary asserted there is def- initely competition between CSX and ACBL. Referring to this com- petition he stated, "We got them to admit under cross examination that there is competition between

ACBL and the railroads." "The merger will, in fact, lessen competition," he continued. "When you take the second largest rail- road, the largest mover of coal, merging with one of the largest, if not the largest barge line, you have significantly affected compe- tition. You've lessened it. And there isn't any public interest I can find that would suggest the

ICC should approve it."

Mr. Geary observed that if the merger is approved, the inland waterways industry will be dras- tically affected. "I would predict that in a relatively short time— and I don't know whether that means five years or 20—certainly our industry as we know it today will have been affected," he said. "And it will shrink."

Speaking on the intermodal is- sue, he said there are no benefits today that cannot be obtained un- der the present system. "There's nothing they propose to do that can't be done under the present situation we operate under," he 46 Maritime Reporter/Engineering News

43

43

45

45