Page 41: of Maritime Reporter Magazine (October 1984)

Read this page in Pdf, Flash or Html5 edition of October 1984 Maritime Reporter Magazine

the account of Transatlantic AB, one of the three Swedish partners in the ACL consortium.

MacGregor-Navire lists the ad- vantages of the new StackCell sys- tem as follows: • Increased number of fully loaded containers that can be loaded in one stack. • Wide flexibility in container stow- ing distribution. • No loose lashing, twist locks, or joining cones required. • Elimination of any manual lash- ing. • Risk of accidents minimized. • No need for checking or re- tightening of lashing during sea voyage. • Quicker placing or "spotting" of containers. • Handling operations can start without any preparation or unlash- ing work. •No waiting for intermediate lash- ing or work after completion. • Easy and safe access to reefer con- tainers.

These considerable advantages have been achieved after much pre- liminary design work and prototype testing carried out by the efforts and expertise of ACL, TransConsul- tants, and MacGregor-Navire.

The most obvious vessel that would gain maximum advantage from weatherdeck cell guides is the fully cellular containership. Other applications envisaged by MacGre- gor-Navire include the feeder ship, the bulk/container carrier, the open bulk carrier, and the whole spec- trum of CONRO, RO/RO, and RO

LO designs.

For further information on the

StackCell system.

Circle 34 on Reader Service Card

MARATHON LETOURNEAU

Marathon LeTourneau Company introduced a new line of marine pedestal cranes with solid-state electronics at the Offshore Technol- ogy Conference last year. The three new cranes are the 50-ton-capacity

PCM-120SS, the 55-ton PCM"- 220SS, and the 75-ton PCM-350SS.

All three can be with standard and optional features that can tailor the cranes to perform all lifting require- ments for materials, equipment, and personnel on offshore drilling and production platforms.

These cranes have a single ac power source rather than a motor/ generator arrangement; micropro- cessors control power flow to all drive motors. As each electric motor is individually and precisely con- trolled by solid-state technology, the new cranes function with a high degree of efficiency, offer faster lift- ing speeds with loads, and feature smoothness of operation. The solid- state controls also provide precise control of current flow, voltage, and operating temperatures. These fea- tures translate into extended service life and minimum maintenance for motors, gears, and other moving parts.

Electrical power requirements are the same for the three units: stan- dard commercial, 600-volt, 60-

Hertz, 3-phase, 500-amp external supply. An integrated, solid-state silicon controlled rectifier provides dc power to each drive system. Peak power requirement under maximum load, dual function, 20-minute con- tinuous duty with dc dynamic brak- ing is 250 kva at 0.7 power factor.

The power system for all three cranes consists of Marathon Le-

Tourneau N-7 dc electric motors with N drivers for hoist and lifting functions. A D-10 electric motor with #5 gearbox provides power for crane swing. Remote control is stan- dard, with controls terminating at a spring-centered, infinitely variable potentiometer controller located at the operator's station. These cranes can be supplied with an operator's cab as an option.

For more information,

Circle 35 on Reader Service Card

MCELROY MACHINE

McElroy Machine and Mfg. Co.,

Inc. of Biloxi, Miss., began furnish- ing deck machinery to the offshore workboat industry in early 1980.

The company now has three very successful years and has machinery working in all parts of the world.

The latest additions to McElroy's standard line of anchor windlasses, anchor winches, capstans, and tow- ing winches is a line of self-con- tained electrohydraulic tuggers and a line of stern rollers. The hydraulic (continued on page 40)

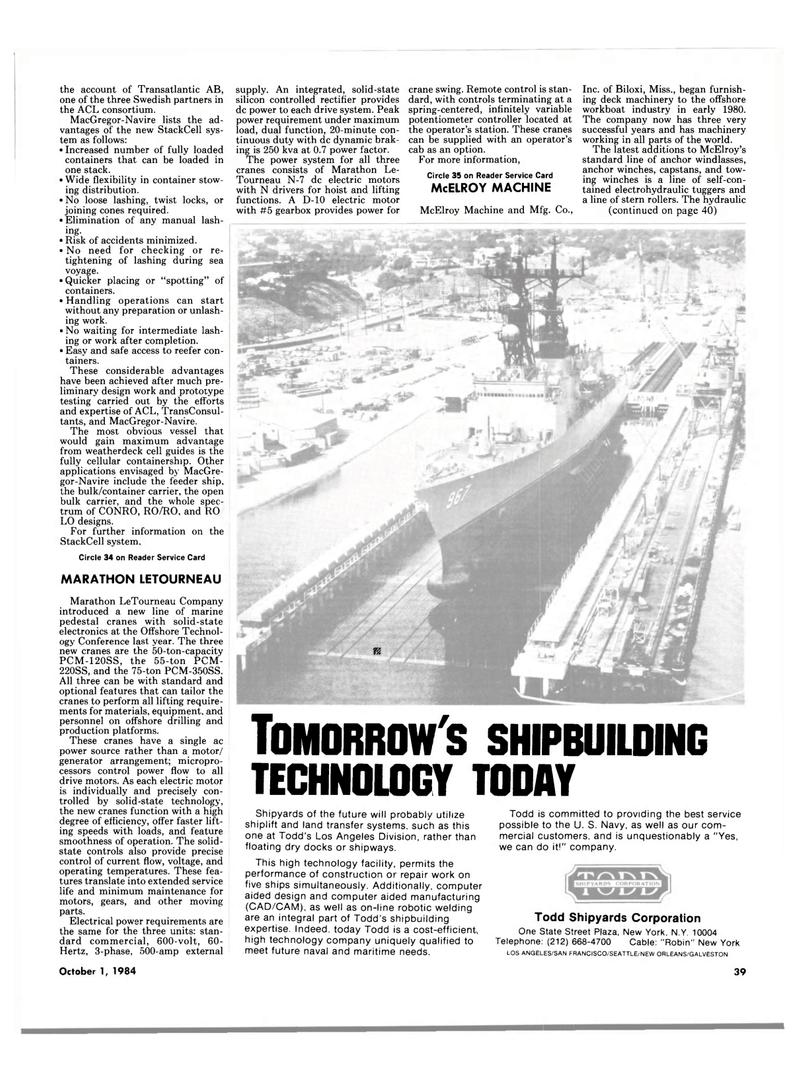

TOMORROW'S SHIPBUILDING

TECHNOLOGY TODAY

Shipyards of the future will probably utilize shiplift and land transfer systems, such as this one at Todd's Los Angeles Division, rather than floating dry docks or shipways.

This high technology facility, permits the performance of construction or repair work on five ships simultaneously. Additionally, computer aided design and computer aided manufacturing (CAD/CAM), as well as on-line robotic welding are an integral part of Todd's shipbuilding expertise. Indeed, today Todd is a cost-efficient, high technology company uniquely qualified to meet future naval and maritime needs.

Todd is committed to providing the best service possible to the U. S. Navy, as well as our com- mercial customers, and is unquestionably a "Yes, we can do it!" company.

Todd Shipyards Corporation

One State Street Plaza, New York. N.Y. 10004

Telephone: (212) 668-4700 Cable: "Robin" New York

LOS ANGELES/SAN FRANCISCO/SEATTLE/NEW ORLEANS/GALVESTON -y

October 1, 1984 39

40

40

42

42