Page 25: of Maritime Reporter Magazine (November 1984)

Read this page in Pdf, Flash or Html5 edition of November 1984 Maritime Reporter Magazine

Racor Offers Literature

On Its New Spin-On Fuel

Filter/Water Separator

Racor Industries, Inc. of Modesto,

Calif., has literature available on the company's new Spin-On Fuel Filter/

Water Separator which the compa- ny says achieves levels of water sep- aration and particulate removal that previously required two or three separate units.

Under the heading "One Head Is

Better Than Three," the literature, illustrated with color photographs, explains that the key component of the Racor Spin-On Fuel Filter/

Water Separator is one die-cast alu- minum head, now being OEM in- stalled as standard equipment. The head accommodates one of three spin-on filter options: Filter Type I provides vacuum or pressure side high-capacity solids removal with water sump; Filter Type II is a vacu- um side dual-media element that optimizes water and particulates re- moval down to two microns; and Fil- ter type III is a pressure side ele- ment with four distinct media that capture particulates while coales- cing and separating emulsified water. Filter Types II and III are installed with a clear impact-resis- tant collection bowl or metal bowl for severe conditions.

Racor says that when two or three fuel filters (primary, secondary and water separator) are replaced by one, manufacturing costs are dra- matically reduced and at the same time, the new system gives users flexibility through a series of up- gradable spin-on filters and accesso- ries that will meet their filtration needs in any application. Standard features include primer pump, check ball, bleed vent and dual out- let ports for ease of installation. For cold weather starting and running, an electrical in-filter heater is an optional feature. Water sensor indi- cators may also be specified.

For further information and a free copy of the literature from Racor,

Circle 19 on Reader Service Card

Airco Introduces New

Pulsed Welding Systems — Literature Available

Airco Welding Products has an- nounced the introduction of the newest member of its family of

Pulse Arc™ welding systems for pulsed spray transfer welding. The

Pulse Arc 500 system, like the

Pulse Arc 350 model, is designed around the pulsed spray process.

The process allows for spatter-free welding and excellent arc control in applications ranging from high deposition out-of-position welding on thick plate to smooth, low-dis- tortion welding on thin gauge materials.

The Pulse Arc 500 system has the power to handle large diame- ter cored wires up to 3/32 inch and can pulse Metal-Cor® 6 wire for high deposition rates. The system also has exceptional smaller di- ameter performance characteris-

November 1, 1984 27 tics. Like the Pulse Arc 350, the 500 model is a complete system consisting of a transistorized 500- ampere air-cooled or 550 ampere water-cooled gun. The fully inte- grated machine takes the nor- mally complex engineering re- quirements of pulsed spray welding and translates them into a few simple pushbutton functions—at a price comparable to a standard

MIG package.

The pushbuttons and toggle switches allow the operator to se- lect among pulse, spray and dip transfer processes. He then presses the appropriate switches for the required wire diameter and shield- ing gas, and he's ready to go. A single knob on the remote pendant simultaneously sets welding cur- rent, voltage, wire feed speed, and pulse frequency. The advanced solid-state circuitry automatically controls all parameters.

The system is pre-programmed for stainless and mild steels, but other wires, such as silicon bronze and aluminum can be used by re- ferring to the easy-to-read process selector charts. The Pulse Arc 500 system is well suited for plants where one machine is needed to perform several welding operations.

For further information and free literature on the Pulse Arc 500 system,

Circle 30 on Reader Service Card »

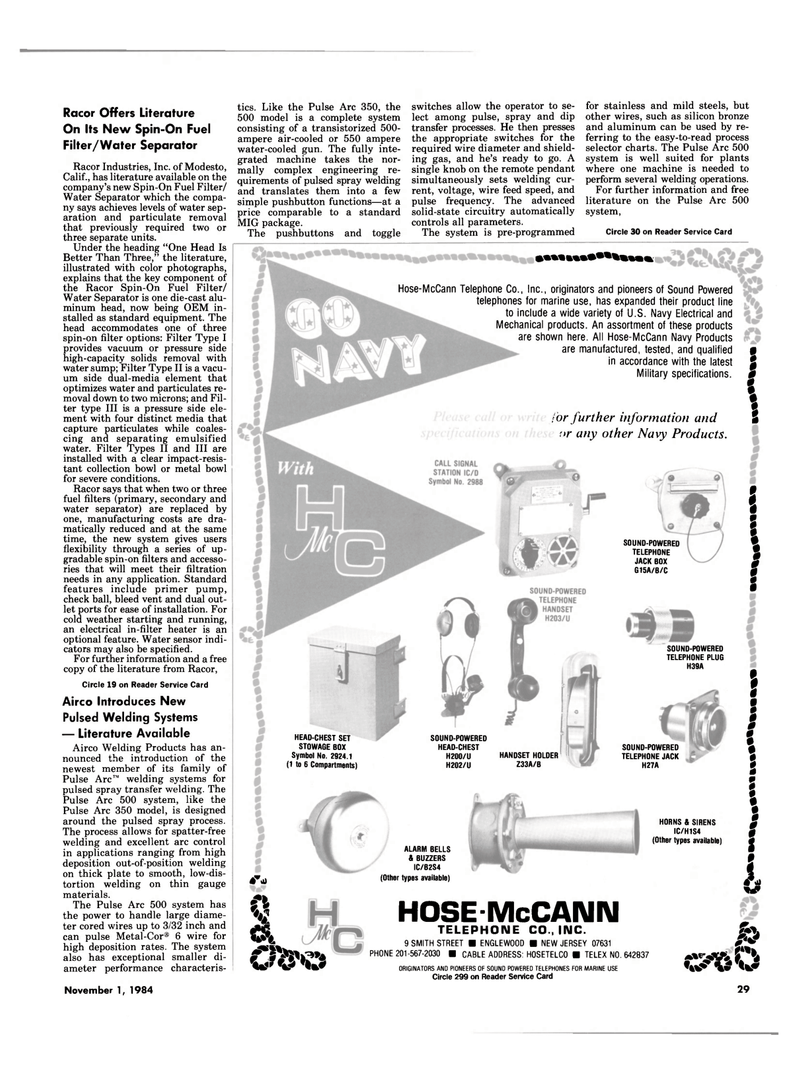

Hose-McCann Telephone Co., Inc., originators and pioneers of Sound Powered telephones for marine use, has expanded their product line to include a wide variety of U.S. Navy Electrical and

Mechanical products. An assortment of these products are shown here. All Hose-McCann Navy Products are manufactured, tested, and qualified in accordance with the latest

Military specifications. for further information and or any other Navy Products.

SOUND-POWERED

TELEPHONE

JACK BOX

G15A/B/C

HEAD-CHEST SET

STOWAGE BOX

Symbol No. 2924.1 (1 to 6 Compartments)

SOUND-POWERED

HEAD-CHEST

H200/U

H202/U

HANDSET HOLDER

Z33A/B

SOUND-POWERED

TELEPHONE JACK

H27A 4T

Q

CM

Ctoo

ALARM BELLS & BUZZERS

IC/B2S4 (Other types available)

HOSE McCAIMIM

TELEPHONE CO., INC. 9 SMITH STREET • ENGLEWOOD • NEW JERSEY 07631

PHONE 201-567-2030 • CABLE ADDRESS: H0SETELC0 • TELEX NO. 642837

ORIGINATORS AND PIONEERS OF SOUND POWERED TELEPHONES FOR MARINE USE

Circle 299 on Reader Service Card 0 1

I

I

I i i i 0 & r^XiO 29

SOUND-POWERED

TELEPHONE PLUG

H39A

HORNS & SIRENS

IC/H1S4 (Other types available)

24

24

26

26