Page 96: of Maritime Reporter Magazine (November 1984)

Read this page in Pdf, Flash or Html5 edition of November 1984 Maritime Reporter Magazine

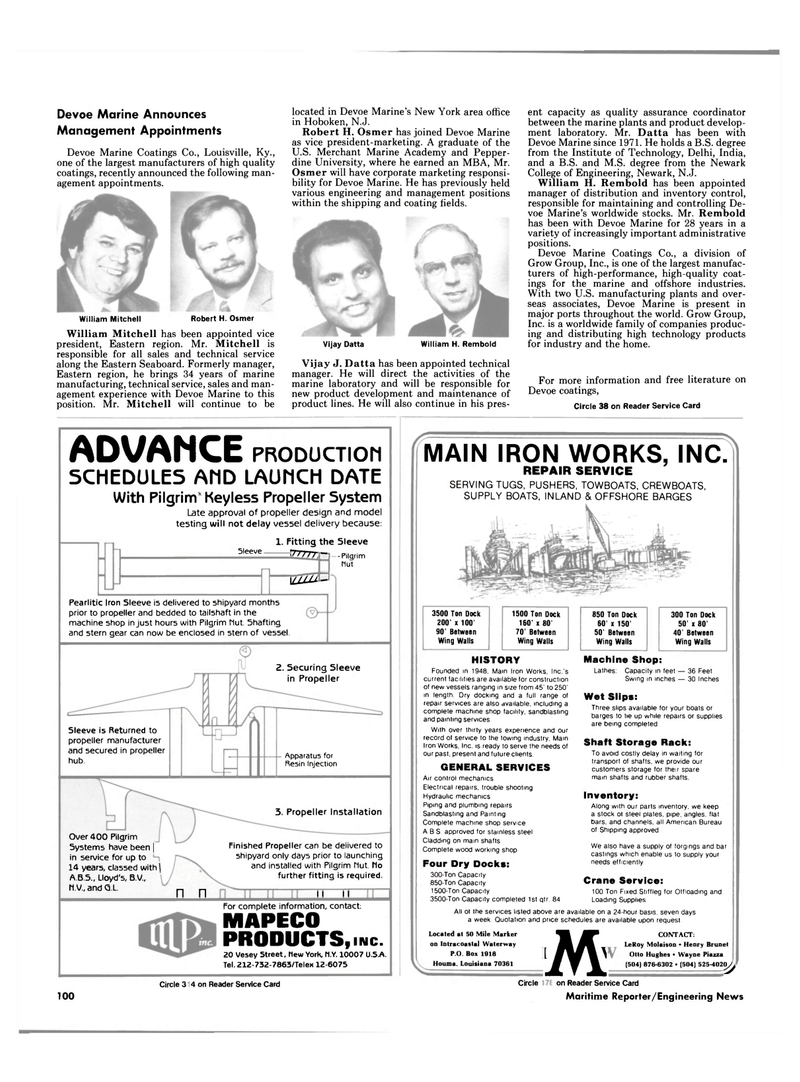

ent capacity as quality assurance coordinator between the marine plants and product develop- ment laboratory. Mr. Datta has been with

Devoe Marine since 1971. He holds a B.S. degree from the Institute of Technology, Delhi, India, and a B.S. and M.S. degree from the Newark

College of Engineering, Newark, N.J.

William H. Rembold has been appointed manager of distribution and inventory control, responsible for maintaining and controlling De- voe Marine's worldwide stocks. Mr. Rembold has been with Devoe Marine for 28 years in a variety of increasingly important administrative positions.

Devoe Marine Coatings Co., a division of

Grow Group, Inc., is one of the largest manufac- turers of high-performance, high-quality coat- ings for the marine and offshore industries.

With two U.S. manufacturing plants and over- seas associates, Devoe Marine is present in major ports throughout the world. Grow Group,

Inc. is a worldwide family of companies produc- ing and distributing high technology products for industry and the home.

For more information and free literature on

Devoe coatings,

Circle 38 on Reader Service Card located in Devoe Marine's New York area office in Hoboken, N.J.

Robert H. Osmer has joined Devoe Marine as vice president-marketing. A graduate of the

U.S. Merchant Marine Academy and Pepper- dine University, where he earned an MBA, Mr.

Osmer will have corporate marketing responsi- bility for Devoe Marine. He has previously held various engineering and management positions within the shipping and coating fields.

Vijay Datta

Vijay J. Datta has been appointed technical manager. He will direct the activities of the marine laboratory and will be responsible for new product development and maintenance of product lines. He will also continue in his pres-

Devoe Marine Announces

Management Appointments

Devoe Marine Coatings Co., Louisville, Ky., one of the largest manufacturers of high quality coatings, recently announced the following man- agement appointments.

William Mitchell has been appointed vice president, Eastern region. Mr. Mitchell is responsible for all sales and technical service along the Eastern Seaboard. Formerly manager,

Eastern region, he brings 34 years of marine manufacturing, technical service, sales and man- agement experience with Devoe Marine to this position. Mr. Mitchell will continue to be

William Mitchell Robert H. Osmer

ADVANCE PRODUCTION

SCHEDULES AMD LAUMCH DATE

With Pilgrim Keyless Propeller System

Late approval of propeller design and model testing will not delay vessel delivery because: 5leeve. 1. Fitting the 5leeve —rr7vm "IZZZZXJ - Pilgrim hut

Pearlitic Iron Sleeve is delivered to shipyard months prior to propeller and bedded to tailshaft in the machine shop in just hours with Pilgrim Mut. Shafting and stern gear can now be enclosed in stern of vessel. 2. Securing Sleeve in Propeller

Sleeve is Returned to propeller manufacturer and secured in propeller hub. Apparatus for Resin Injection

Over 400 Pilgrim

Systems have been J in service for up to 14 years, classed with ]

A.B.5., Lloyd's, B.V.,

M.V., and G.L 3. Propeller Installation

Finished Propeller can be delivered to shipyard only days prior to launching and installed with Pilgrim Hut. Mo further fitting is required. n n ii ii

For complete information, contact: MAPECO

PRODUCTS, INC. 20 Vesey Street, Mew York, MY. 10007 U.S.A.

Tel. 212-732-7863/Telex 12-6075

Circle 324 on Reader Service Card

MAIN IRON WORKS, INC.

REPAIR SERVICE

SERVING TUGS, PUSHERS, TOWBOATS, CREWBOATS,

SUPPLY BOATS, INLAND & OFFSHORE BARGES 3500 Ton Dock 200' x 100' 90' Between

Wing Walls 1500 Ton Dock 160' x 80' 70' Between

Wing Walls 850 Ton Dock 60' x 150' 50' Between

Wing Walls 300 Ton Dock 50' x 80' 40' Between

Wing Walls

HISTORY

Founded in 1948. Main Iron Works, Inc.'s current facilities are available for construction of new vessels ranging in size from 45' to 250' in length. Dry docking and a full range of repair services are also available, including a complete machine shop facility, sandblasting and painting services

With over thirty years experience and our record of service to the towing industry. Main

Iron Works, Inc. is ready to serve the needs of our past, present and future clients.

GENERAL SERVICES

Air control mechanics

Electrical repairs, trouble shooting

Hydraulic mechanics

Piping and plumbing repairs

Sandblasting and Painting

Complete machine shop service

A B S approved for stainless steel

Cladding on main shafts

Complete wood working shop

Four Dry Docks: 300-Ton Capacily 850-Ton Capacity 1500-Ton Capacity 3500-Ton Capacity completed 1st qtr 84

Machine Shop:

Lathes: Capacity in feet — 36 Feet

Swing in inches — 30 Inches

Wet Slips:

Three slips available for your boats or barges to tie up while repairs or supplies are being completed

Shaft Storage Rack:

To avoid costly delay in waiting for transport of shafts, we provide our customers storage for their spare main shafts and rubber shafts.

Inventory:

Along with our parts inventory, we keep a stock ot steel plates, pipe, angles, flat bars, and channels, all American Bureau of Shipping approved

We also have a supply of forgings and bar castings which enable us to supply your needs efficiently

Crane Service: 100 Ton Fixed Stiffleg for Offloading and

Loading Supplies

All ot the services listed above are available on a 24-hour basis, seven days a week Quotation and price schedules are available upon request

Located at 50 Mile Marker on Intracoastal Waterway

P.O. Box 1918

Houma, Louisiana 70361 M

CONTACT:

LeRoy Molaison • Henry Brunei

Otto Hughes • Wayne Piazza (504) 876-6302 • (504) 525-402^ 100

Circle 295 on Reader Service Card

Maritime Reporter/Engineering News

William H. Rembold

95

95

97

97