Page 9: of Maritime Reporter Magazine (November 15, 1984)

Read this page in Pdf, Flash or Html5 edition of November 15, 1984 Maritime Reporter Magazine

the company's sales representatives, distributors, and direct sales force.

Mr. Rothermel comes to Tele-

Systems with more than 30 years of experience in the communications industry. Most recently, he served as account executive for the Federal

Systems Division of Northern Tele- com, where he performed accounts analysis, developed strategy, and coordinated sales efforts. He has also held sales management posi- tions with the Pulsecom Division of

Harvey Hubbel, Inc.; GTE Lenkurt,

Inc.; General Electric; and the Phil- co-Ford Corporation.

Comsat TeleSystems, located in

Fairfax, Va., designs, manufactures, markets, and provides worldwide service and support for analog and digital signal processing equipment and systems.

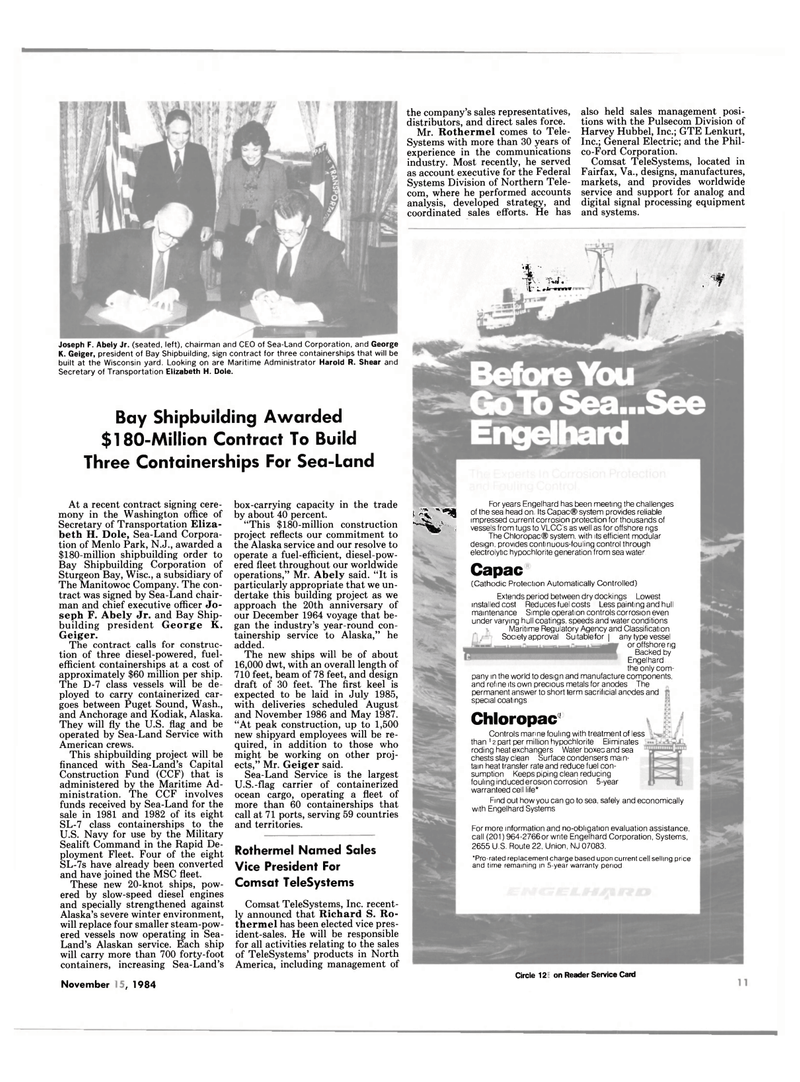

Joseph F. Abely Jr. (seated, left), chairman and CEO of Sea-Land Corporation, and George

K. Geiger, president of Bay Shipbuilding, sign contract for three containerships that will be built at the Wisconsin yard. Looking on are Maritime Administrator Harold R. Shear and

Secretary of Transportation Elizabeth H. Dole. r •fv &f.

I|r *fK~wewv9 . 1

Bay Shipbuilding Awarded $l 80-Million Contract To Build

Three Containerships For Sea-Land

At a recent contract signing cere- mony in the Washington office of

Secretary of Transportation Eliza- beth H. Dole, Sea-Land Corpora- tion of Menlo Park, N.J., awarded a $180-million shipbuilding order to

Bay Shipbuilding Corporation of

Sturgeon Bay, Wise., a subsidiary of

The Manitowoc Company. The con- tract was signed by Sea-Land chair- man and chief executive officer Jo- seph F. Abely Jr. and Bay Ship- building president George K.

Geiger.

The contract calls for construc- tion of three diesel-powered, fuel- efficient containerships at a cost of approximately $60 million per ship.

The D-7 class vessels will be de- ployed to carry containerized car- goes between Puget Sound, Wash., and Anchorage and Kodiak, Alaska.

They will fly the U.S. flag and be operated by Sea-Land Service with

American crews.

This shipbuilding project will be financed with Sea-Land's Capital

Construction Fund (CCF) that is administered by the Maritime Ad- ministration. The CCF involves funds received by Sea-Land for the sale in 1981 and 1982 of its eight

SL-7 class containerships to the

U.S. Navy for use by the Military

Sealift Command in the Rapid De- ployment Fleet. Four of the eight

SL-7s have already been converted and have joined the MSC fleet.

These new 20-knot ships, pow- ered by slow-speed diesel engines and specially strengthened against

Alaska's severe winter environment, will replace four smaller steam-pow- ered vessels now operating in Sea-

Land's Alaskan service. Each ship will carry more than 700 forty-foot containers, increasing Sea-Land's

November 15, 1984 box-carrying capacity in the trade by about 40 percent. "This $180-million construction project reflects our commitment to the Alaska service and our resolve to operate a fuel-efficient, diesel-pow- ered fleet throughout our worldwide operations," Mr. Abely said. "It is particularly appropriate that we un- dertake this building project as we approach the 20th anniversary of our December 1964 voyage that be- gan the industry's year-round con- tainership service to Alaska," he added.

The new ships will be of about 16,000 dwt, with an overall length of 710 feet, beam of 78 feet, and design draft of 30 feet. The first keel is expected to be laid in July 1985, with deliveries scheduled August and November 1986 and May 1987. "At peak construction, up to 1,500 new shipyard employees will be re- quired, in addition to those who might be working on other proj- ects," Mr. Geiger said.

Sea-Land Service is the largest

U.S.-flag carrier of containerized ocean cargo, operating a fleet of more than 60 containerships that call at 71 ports, serving 59 countries and territories.

For years Engelhard has been meeting the challenges gsljl"^^! of the sea head on. Its Capac® system provides reliable .J^i .. impressed current corrosion protection for thousands of

HBR vessels from tugs to VLCC s as well as for offshore rigs

The Chloropac® system, with its efficient modular design, provides continuous fouling control through electrolytic hypochlorite generation from sea water

Rothermel Named Sales

Vice President For

Comsat TeleSystems

Comsat TeleSystems, Inc. recent- ly announcd that Richard S. Ro- thermel has been elected vice pres- ident-sales. He will be responsible for all activities relating to the sales of TeleSystems' products in North

America, including management of

Capac (Cathodic Protection Automatically Controlled)

Extends period between dry dockings Lowest installed cost Reduces fuel costs Less painting and hull maintenance Simple operation controls corrosion even under varying hull coatings, speeds and water conditions

Maritime Regulatory Agency and Classification

Society approval Suitablefor | any type vessel or offshore rig

Backed by

Engelhard the oniy com- pany in the world to design and manufacture components, and refine its own precious metals for anodes The permanent answer to short term sacrificial anodes and special coatings

Chloropac"

Controls manne fouling with treatment of less than 12 part per million hypochlorite Eliminates roding heat exchangers Water boxes and sea chests stay clean Surface condensers main- tain heat transfer rate and reduce fuel con- sumption Keeps piping clean reducing fouling induced erosion corrosion 5-year warranteed cell life*

Find out how you can go to sea, safely and economically with Engelhard Systems

For more information and no-obligation evaluation assistance, call (201) 964-2766or write Engelhard Corporation, Systems, 2655 U.S. Route 22, Union, NJ 07083. "Pro rated replacement charge based upon current cell selling price and time remaining in 5-year warranty period

Circle 120 on Reader Service Card SIMRAD

8

8

10

10