Page 13: of Maritime Reporter Magazine (January 1985)

Read this page in Pdf, Flash or Html5 edition of January 1985 Maritime Reporter Magazine

CMC DN15 portable VHF radios; one MCS 9000 satellite communica- tions system; and a Skanti watch receiver. Other equipment will in- clude gyrocompass with autopilot, portable joystick, emergency loca- tor/transmitter, and crewcall/talk- back system.

Accommodations will be provided for six officers and six crew, all in single cabins, along with space for 12 supernumeraries. The accommo- dations will be fully air conditioned and designed for electric heating.

Marystown Shipyard manage- ment is very excited about the po- tential for this new vessel of its own design, and is confident that a buyer will be found before the vessel is completed in the fall of 1985.

Hull No. 37

Partial Suppliers List

Main engines (4) Deutz

Reduction gearboxes (2)

Lohmann & Stolterfoht

Propellers & shafts (2) Lips

Bow & stern thrusters Ulstein

Shaft alternators (2) Siemens

Diesel generator engines (2) . . Detroit

FO & LO purifiers Alfa-Laval

Pumps Allweiler; Viking

Deck machinery . . Hydraulik Bratvaag

Radars (2) & speed log JRC

ADF & depth sounder Simrad

Radiotelephones (2) Sailor

VHF radios (2) CMC

Satcom system MCS

Watch receiver Skanti

Todd Awarded $96-Million

Navy Contract To Build

Guided-Missile Frigate

The Los Angeles Division of Todd

Shipyards Corporation has been awarded a $96.1-million U.S. Navy contract for the construction of an- other guided-missile frigate of the

Oliver Hazard Perry (FFG-7) Class.

This brings to 31 the number of

FFGs awarded to Todd. The Los

Angeles Division has completed 14 of the 18 contracted for, and the

Seattle Division has delivered 12 of the 13 awarded there.

BIW Will Get $383.6-Million

Navy Contract To Build

Two Aegis CG-47 Cruisers

Bath Iron Works Corporation (BIW) in Maine is the apparent suc- cessful bidder for two of the three

Aegis guided-missile cruisers of the

Ticonderoga (CG-47) Class that the

U.S. Navy ordered recently under the FY 85 shipbuilding program.

The other ship was awarded to In- galls Shipbuilding, which was chos- en as the lead yard when the Aegis cruiser program began in 1978. The latest contract brings to four the number of cruisers ordered from

BIW; Ingalls has received orders for a total of 13.

According to BIW president Wil- liam E. Haggett, price was a key factor in the Navy's decision on the latest contracts. "BIW has under- taken major efforts to contain costs, and our pricing on these ships re- flects a management commitment to continue with every initiative necessary to remain ahead of the competition," he said.

BIW, Ingalls, and Todd Ship- yards Corporation are all bidding for the construction of the DDG-51, lead ship in the new Arleigh Burke

Class Aegis guided-missile de- stroyers. Authorized in the FY 85 shipbuilding program, the contract for the DDG-51 is scheduled to be awarded in January 1985.

Westinghouse Receives $3.2-Million Navy Order

For Turbogenerator Work

Westinghouse Electric Corpora- tion, Marine Division, Sunnyvale,

Calif., has been issued a $3,200,000 firm-fixed-price order under a basic ordering agreement to furnish com- ponents and services for the upgrad- ing, repair, and modification of four

Westinghouse ship service turbine generators to be utilized in the over- haul of the USS Lexington (CV-16) at the Philadelphia Naval Shipyard.

Work will be performed in Sunny- vale, and is expected to be com- pleted in May 1985. Contract funds would not have expired at the end of the current fiscal year. The Naval

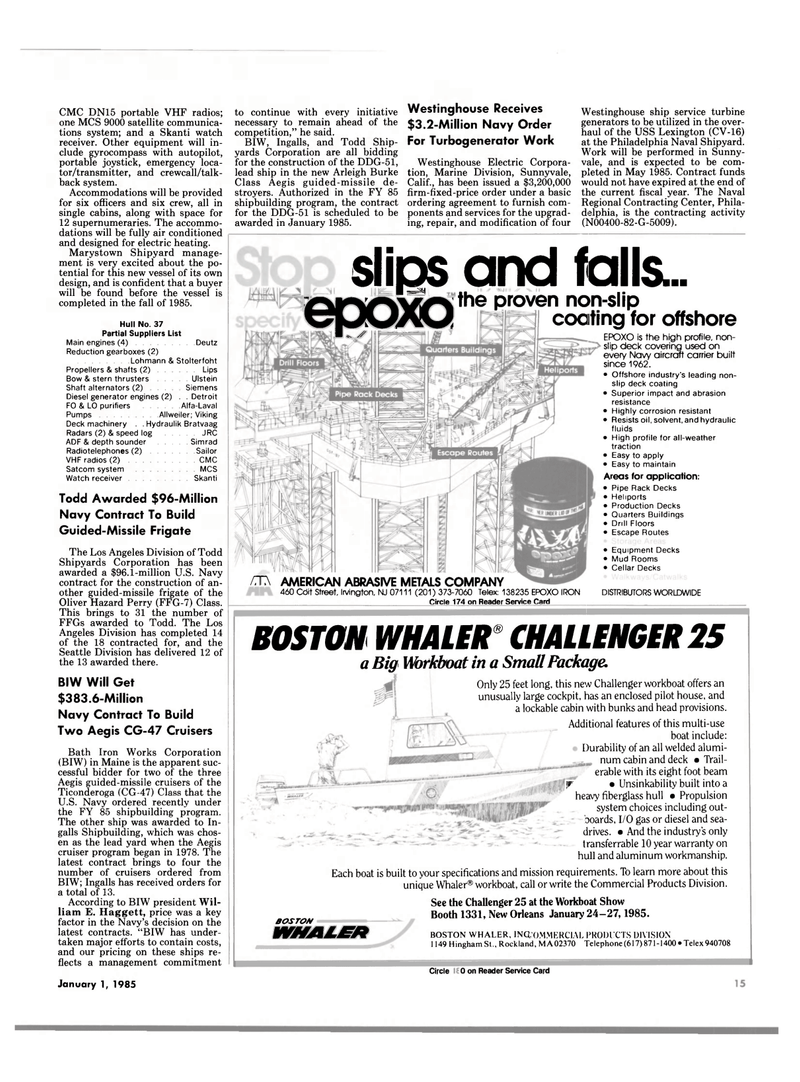

Regional Contracting Center, Phila- delphia, is the contracting activity (N00400-82-G-5009). slips and falls.. epoxo the proven non-slip coating for offshore /X\ AMERICAN ABRASIVE METALS COMPANY 460 CcJit Street, Irvington, NJ 07111 (201) 373-7060 Telex: 138235 EPOXO IRON

Circle 174 on Reader Service Card

EPOXO is the high profile, non- slip deck covering used on every Navy aircraft carrier built since 1962. • Offshore industry's leading non- slip deck coating • Superior impact and abrasion resistance • Highly corrosion resistant • Resists oil, solvent, and hydraulic fluids • High profile for all-weather traction • Easy to apply • Easy to maintain

Areas for application: • Pipe Rack Decks • Heliports • Production Decks • Quarters Buildings • Drill Floors • Escape Routes • Equipment Decks • Mud Rooms • Cellar Decks

DISTRIBUTORS WORLDWIDE

BOSTON WHALER CHALLENGER 25 a Big Workboat in a Small Package.

Only 25 feet long, this new Challenger workboat offers an unusually large cockpit, has an enclosed pilot house, and a lockable cabin with bunks and head provisions.

Additional features of this multi-use boat include:

Durability of an all welded alumi- num cabin and deck • Trail- erable with its eight foot beam

W • Unsinkability built into a heavy fiberglass hull • Propulsion system choices including out- boards, I/O gas or diesel and sea- drives. • And the industry's only transferrable 10 year warranty on hull and aluminum workmanship.

Each boat is built to your specifications and mission requirements. To learn more about this unique Whaler® workboat, call or write the Commercial Products Division.

See the Challenger 25 at the Workboat Show

Booth 1331, New Orleans January 24-27, 1985. BOSTON •

ItWJiLtt BOSTON WHALER, INCCOMMERCIAL PRODUCTS DIVISION 1149 Hingham St., Rockland, MA02370 Telephone(617) 871 -1400 • Telex940708

Circle 200 on Reader Service Card

January 1, 1985 15

12

12

14

14