Page 28: of Maritime Reporter Magazine (June 1985)

Read this page in Pdf, Flash or Html5 edition of June 1985 Maritime Reporter Magazine

Navy

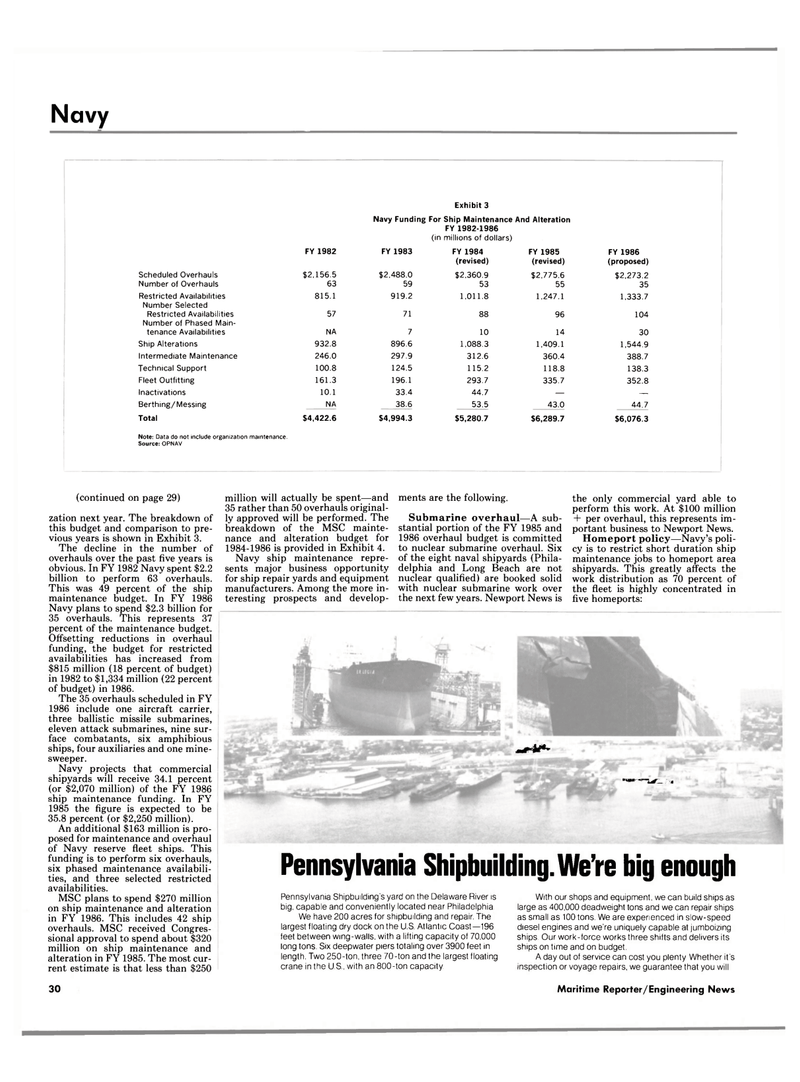

Exhibit 3

Navy Funding For Ship Maintenance And Alteration

FY 1982-1986 (in millions of dollars)

FY 1982 FY 1983 FY 1984 FY 1985 FY 1986 (revised) (revised) (proposed)

Scheduled Overhauls $2,156.5 $2,488.0 $2,360.9 $2,775.6 $2,273.2

Number of Overhauls 63 59 53 55 35

Restricted Availabilities 815.1 919.2 1,011.8 1,247.1 1,333.7

Number Selected

Restricted Availabilities 57 71 88 96 104

Number of Phased Main- tenance Availabilities NA 7 10 14 30

Ship Alterations 932.8 896.6 1,088.3 1,409.1 1,544.9

Intermediate Maintenance 246.0 297.9 312.6 360.4 388.7

Technical Support 100.8 124.5 115.2 118.8 138.3

Fleet Outfitting 161.3 196.1 293.7 335.7 352.8

Inactivations 10.1 33.4 44.7 — —

Berthing/Messing NA 38.6 53.5 43.0 44.7

Total $4,422.6 $4,994.3 $5,280.7 $6,289.7 $6,076.3

Note: Data do not include organization maintenance.

Source: OPNAV (continued on page 29) zation next year. The breakdown of this budget and comparison to pre- vious years is shown in Exhibit 3.

The decline in the number of overhauls over the past five years is obvious. In FY 1982 Navy spent $2.2 billion to perform 63 overhauls.

This was 49 percent of the ship maintenance budget. In FY 1986

Navy plans to spend $2.3 billion for 35 overhauls. This represents 37 percent of the maintenance budget.

Offsetting reductions in overhaul funding, the budget for restricted availabilities has increased from $815 million (18 percent of budget) in 1982 to $1,334 million (22 percent of budget) in 1986.

The 35 overhauls scheduled in FY 1986 include one aircraft carrier, three ballistic missile submarines, eleven attack submarines, nine sur- face combatants, six amphibious ships, four auxiliaries and one mine- sweeper.

Navy projects that commercial shipyards will receive 34.1 percent (or $2,070 million) of the FY 1986 ship maintenance funding. In FY 1985 the figure is expected to be 35.8 percent (or $2,250 million).

An additional $163 million is pro- posed for maintenance and overhaul of Navy reserve fleet ships. This funding is to perform six overhauls, six phased maintenance availabili- ties, and three selected restricted availabilities.

MSC plans to spend $270 million on ship maintenance and alteration in FY 1986. This includes 42 ship overhauls. MSC received Congres- sional approval to spend about $320 million on ship maintenance and alteration in FY 1985. The most cur- rent estimate is that less than $250 million will actually be spent—and 35 rather than 50 overhauls original- ly approved will be performed. The breakdown of the MSC mainte- nance and alteration budget for 1984-1986 is provided in Exhibit 4.

Navy ship maintenance repre- sents major business opportunity for ship repair yards and equipment manufacturers. Among the more in- teresting prospects and develop- ments are the following.

Submarine overhaul—A sub- stantial portion of the FY 1985 and 1986 overhaul budget is committed to nuclear submarine overhaul. Six of the eight naval shipyards (Phila- delphia and Long Beach are not nuclear qualified) are booked solid with nuclear submarine work over the next few years. Newport News is the only commercial yard able to perform this work. At $100 million + per overhaul, this represents im- portant business to Newport News.

Homeport policy—Navy's poli- cy is to restrict short duration ship maintenance jobs to homeport area shipyards. This greatly affects the work distribution as 70 percent of the fleet is highly concentrated in five homeports: mdHM*1- *mm> i m

Pennsylvania Shipbuilding. We're big enough

Pennsylvania Shipbuilding's yard on the Delaware River is big, capable and conveniently located near Philadelphia

We have 200 acres for shipbuilding and repair. The largest floating dry dock on the U.S. Atlantic Coast—196 feet between wing-walls, with a lifting capacity of 70.000 long tons. Six deepwater piers totaling over 3900 feet in length Two 250-ton, three 70-ton and the largest floating crane in the U.S., with an 800-ton capacity.

With our shops and equipment, we can build ships as large as 400,000 deadweight tons and we can repair ships as small as 100 tons. We are experienced in slow-speed diesel engines and we're uniquely capable at jumboizing ships. Our work-force works three shifts and delivers its ships on time and on budget.

A day out of service can cost you plenty Whether it's inspection or voyage repairs, we guarantee that you will 30 Maritime Reporter/Engineering News

27

27

29

29