Page 20: of Maritime Reporter Magazine (July 15, 1985)

Read this page in Pdf, Flash or Html5 edition of July 15, 1985 Maritime Reporter Magazine

West Coast Shipyards (continued) 22!/2-foot tour vessel for Alaska shortly, and a 110- by 26-foot din- ner/cruise vessel to follow. Also planned is a 120- by 24-foot tour boat for use in the Northwest.

CONTINENTAL MARITIME

Circle 31 on Reader Service Card

Continental Maritime has two fa- cilities on the West Coast, one in

San Francisco and a second in San

Diego.

The company recently accepted delivery of the" M.A.N.-GHH built drydock, Mission Bay (MARITIME

REPORTER/Engineering News,

May 15, 1985).

Innovative features of the dry- dock include an advanced system of adjustable keel and bilge blocks de- veloped by M.A.N.-GHH and modi- fied specifically for the docking of

U.S. Navy ships with large deadrise.

In addition, the dock has been out- fitted with a sonar dome pit, 102

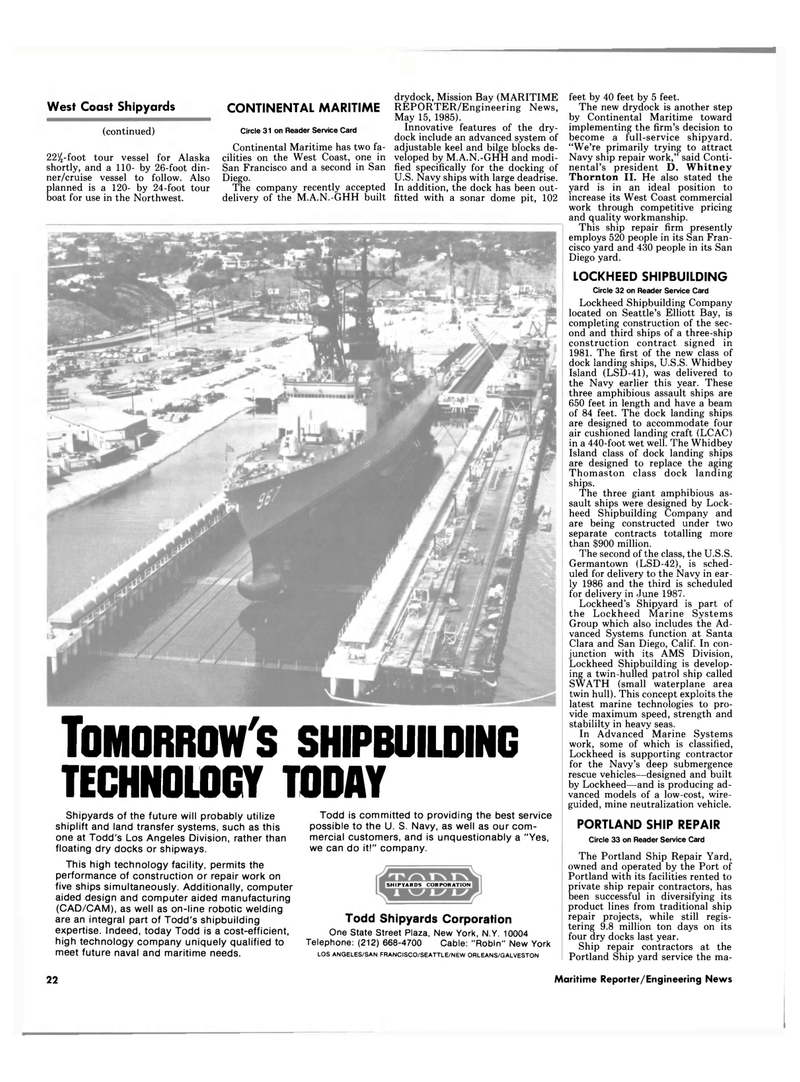

TOMORROW'S SHIPBUILDING

TECHNOLOGY TODAY

Shipyards of the future will probably utilize shiplift and land transfer systems, such as this one at Todd's Los Angeles Division, rather than floating dry docks or shipways.

This high technology facility, permits the performance of construction or repair work on five ships simultaneously. Additionally, computer aided design and computer aided manufacturing (CAD/CAM), as well as on-line robotic welding are an integral part of Todd's shipbuilding expertise. Indeed, today Todd is a cost-efficient, high technology company uniquely qualified to meet future naval and maritime needs.

Todd is committed to providing the best service possible to the U. S. Navy, as well as our com- mercial customers, and is unquestionably a "Yes, we can do it!" company.

SHIPYARDS CORPORATION

Todd Shipyards Corporation

One State Street Plaza, New York, N.Y. 10004

Telephone: (212) 668-4700 Cable: "Robin" New York

LOS ANGELES/SAN FRANCISCO/SEATTLE/NEW ORLEANS/GALVESTON feet by 40 feet by 5 feet.

The new drydock is another step by Continental Maritime toward implementing the firm's decision to become a full-service shipyard. "We're primarily trying to attract

Navy ship repair work," said Conti- nental's president D. Whitney

Thornton II. He also stated the yard is in an ideal position to increase its West Coast commercial work through competitive pricing and quality workmanship.

This ship repair firm presently employs 520 people in its San Fran- cisco yard and 430 people in its San

Diego yard.

LOCKHEED SHIPBUILDING

Circle 32 on Reader Service Card

Lockheed Shipbuilding Company located on Seattle's Elliott Bay, is completing construction of the sec- ond and third ships of a three-ship construction contract signed in 1981. The first of the new class of dock landing ships, U.S.S. Whidbey

Island (LSD-41), was delivered to the Navy earlier this year. These three amphibious assault ships are 650 feet in length and have a beam of 84 feet. The dock landing ships are designed to accommodate four air cushioned landing craft (LCAC) in a 440-foot wet well. The Whidbey

Island class of dock landing ships are designed to replace the aging

Thomaston class dock landing ships.

The three giant amphibious as- sault ships were designed by Lock- heed Shipbuilding Company and are being constructed under two separate contracts totalling more than $900 million.

The second of the class, the U.S.S.

Germantown (LSD-42), is sched- uled for delivery to the Navy in ear- ly 1986 and the third is scheduled for delivery in June 1987.

Lockheed's Shipyard is part of the Lockheed Marine Systems

Group which also includes the Ad- vanced Systems function at Santa

Clara and San Diego, Calif. In con- junction with its AMS Division,

Lockheed Shipbuilding is develop- ing a twin-hulled patrol ship called

SWATH (small waterplane area twin hull). This concept exploits the latest marine technologies to pro- vide maximum speed, strength and stabililty in heavy seas.

In Advanced Marine Systems work, some of which is classified,

Lockheed is supporting contractor for the Navy's deep submergence rescue vehicles—designed and built by Lockheed—and is producing ad- vanced models of a low-cost, wire- guided, mine neutralization vehicle.

PORTLAND SHIP REPAIR

Circle 33 on Reader Service Card

The Portland Ship Repair Yard, owned and operated by the Port of

Portland with its facilities rented to private ship repair contractors, has been successful in diversifying its product lines from traditional ship repair projects, while still regis- tering 9.8 million ton days on its four dry docks last year.

Ship repair contractors at the

Portland Ship yard service the ma- 22 Maritime Reporter/Engineering News

19

19

21

21