Page 25: of Maritime Reporter Magazine (September 15, 1985)

Read this page in Pdf, Flash or Html5 edition of September 15, 1985 Maritime Reporter Magazine

other divisions are available to the

Shipbuilding Division—including a well equipped Heavy Machine Shop and a large Stress Relieving Fur- nace.

The shipyard has been using the

AUTOKON CAD/CAM system for steel definition and manufacturing since 1970, and in late 1983, pur- chased the latest interactive AU-

TOKON modules that will serve for both engineering .and manufactur- ing.

Housed in a new CAD/CAM facil- ity, containing 12 terminals and lo- cated adjacent to the drawing of- fices, MIL has one of the most pow- erful CAD/CAM facilities for ship- building.

Apart from the design and draft- ing capabilities, MIL also uses the "SPAR" planning and control mod- ules for work planning, estimating and material control, etc.

The CAD/CAM software from

GE, called CALMA is also being used in the shipyard, but more spe- cifically for the Hydro-Electric Di- vision at this time.

MARYSTOWN SHIPYARD

Circle 31 on Reader Service Card

Marystown Shipyard Lim- ited, Marystown, Newfoundland.

Marystown Shipyard Limited is situated in Mortier Bay, on the Bu- rin Peninsula, Newfoundland. The port is ice free all year round and is strategically located close to all

East/West shipping traffic lanes, as well as being very convenient to all local shipping and trawler opera- tions. Mortier Bay is a sheltered deepwater port with depths in ex- cess of 200 feet and is an ideal loca- tion for doing work afloat on oil rigs, while offering shelter from the ele- ments.

The yard was completed in 1968 and, in facilities and concept, is one of the more technologically ad- vanced yards of its size in the world.

Shipbuilding: All classes and types of ships to 3,000 L tons dis- placement.

Specialties: Offshore supply and anchor handling tugs. Fishing vessels of all sizes and types.

Ship Repairs: Vessels of all types to 3,000 L tons displacement, syncrolift, marine elevator with transfer capable of drydocking six ships of maximum size at one time.

Dimensions of syncrolift: 76.22 m x 18.29 m x 3,000 L tons displace- ment. An under cover steel prepara- tion, assembly and erection with two 250 ft. building berths under one roof. The Steel Shop has a 1:10

Automatic Flame Cutter, a 600 ton

Rolling and Flanging Press capable of handling plates 30 ft. wide x 1 inch thick, a 300 Brake Press, a 100 ton Gap Press, a 200 ton Cold Bar

Bender and Numerical Control Cut- ting equipment. The Engineering,

Pipefitting, Joiner, Painter and

Electrical Shops are conveniently situated adjacent to all activities and have all the modern equipment necessary for the construction, fit- ting out and repair of all types of vessels.

September 15, 1985

NEWFOUNDLAND

DOCKYARD

Circle 32 on Reader Service Card

Newfoundland Dockyard, St.

John's, Newfoundland.

The Newfoundland Dockyard is strategically situated in the shel- tered, ice-free harbour of St. John's,

Newfoundland—close to the North

Atlantic shipping lanes. In fact, it's the first point of refuge on the

North American shore.

Repairs: Specializing in ship re- pairs, conversions and refit work on all types of commercial, govern- ment, and naval vessels.

NORTHERN ARC

SHIPBUILDERS

Circle 33 on Reader Service Card

Northern Arc Shipbuilders

Ltd., Hay River, Northwest Terri- tories.

A major portion of shipbuilding, conversions and repair needs of companies engaged in MacKenzie

River and Beaufort Sea operations are contracted through Northern

Arc.

Builders of: Ice-class tugs, fer- ries, barges, crew boats, work boats, pollution control vessels.

Ship Repairs: Ships of all types, ship conversions, general repairs and associated services. (continued on page 30)

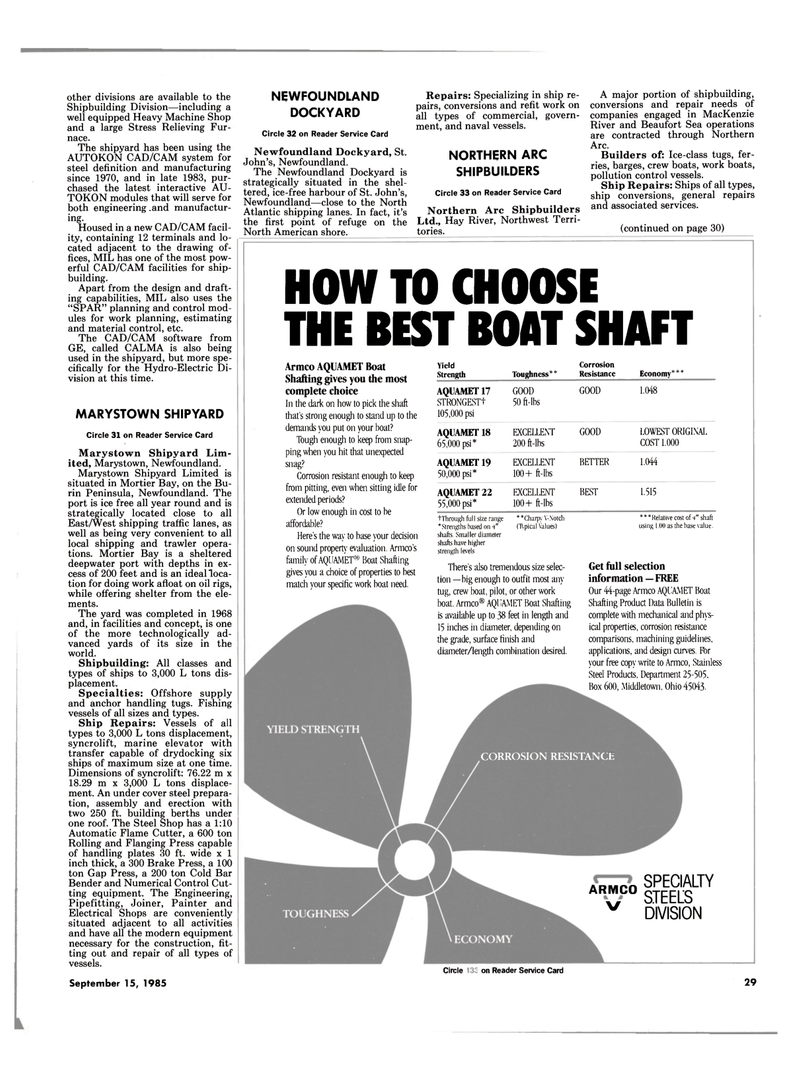

HOW TO CHOOSE THE BEST BOAT SHAFT

Armco AQUAMET Boat

Shafting gives you the most complete choice

In the dark on how to pick the shaft that's strong enough to stand up to the demands you put on your boat?

Tough enough to keep from snap- ping when you hit that unexpected snag?

Corrosion resistant enough to keep from pitting, even when sitting idle for extended periods?

Or low enough in cost to be affordable?

Here's the way to base your decision on sound property evaluation. Armco's family of AQUAMET® Boat Shafting gives you a choice of properties to best match your specific work boat need.

Yield

Strength Toughness**

Corrosion

Resistance Economy* * *

AQUAMET 17

STRONGESTt 105,000 psi

GOOD 50 ft-lbs

GOOD 1.048

AQUAMET 18 65,000 psi*

EXCEI1ENT 200 ft-lbs

GOOD LOWEST ORIGINAL

COST 1.000

AQUAMET 19 50,000 psi*

EXCELLENT 100+ ft-lbs

BETTER 1.044

AQUAMET 22 55,000 psi*

EXCELLENT 100+ ft-lbs

BEST 1.515 tThrough full size range * Strengths based on 4" shafts. Smaller diameter shafts have higher strength levels **Charpy V-Notch (1\pical Values) * * * Relative cost of 4" shaft using 1.00 as the base value.

There's also tremendous size selec- tion —big enough to outfit most any tug, crew boat, pilot, or other work boat. Armco® AQUAMET Boat Shafting is available up to 38 feet in length and 15 inches in diameter, depending on the grade, surface finish and diameter/length combination desired.

Get full selection information — FREE

Our 44-page Armco AQUAMET Boat

Shafting Product Data Bulletin is complete with mechanical and phys- ical properties, corrosion resistance comparisons, machining guidelines, applications, and design curves. For your free copy write to Armco, Stainless

Steel Products, Department 25-505,

Box 600, Middletown, Ohio 45043.

CORROSION RESISTANCE

ARMCO SPECIALTY STEELS v DIVISION

Circle 200 on Reader Service Card 29

24

24

26

26