Page 38: of Maritime Reporter Magazine (October 15, 1985)

Read this page in Pdf, Flash or Html5 edition of October 15, 1985 Maritime Reporter Magazine

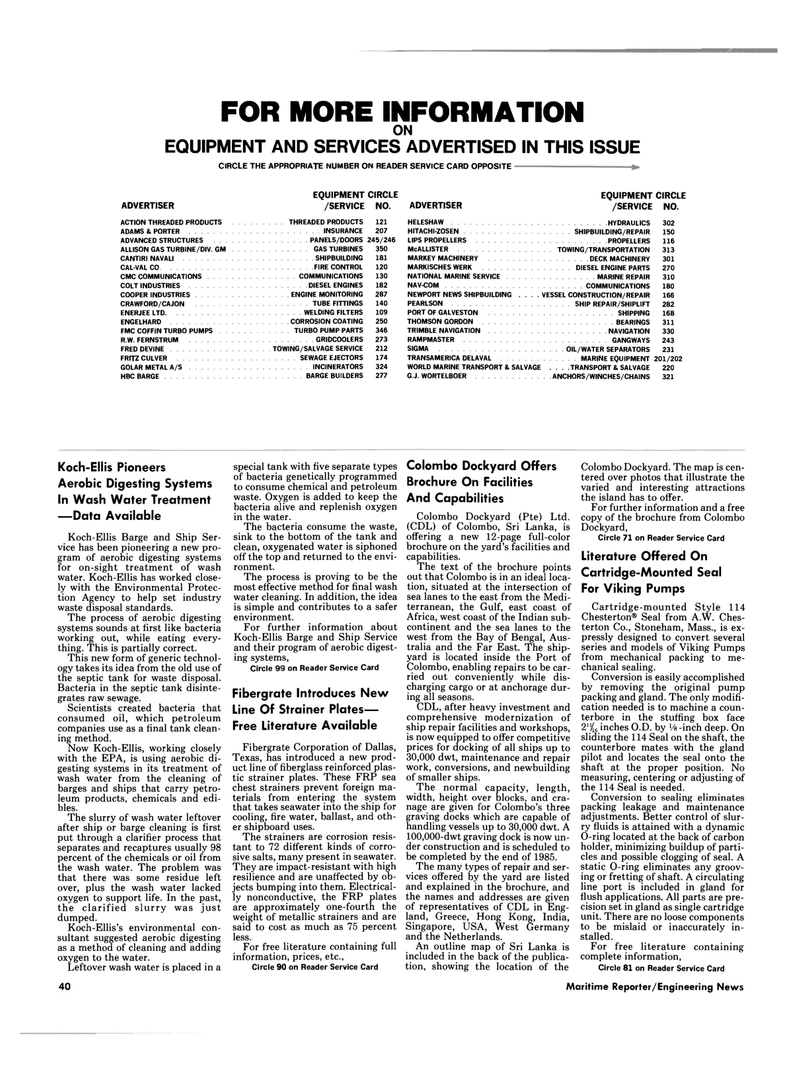

FOR MORE INFORMATION

ON

EQUIPMENT AND SERVICES ADVERTISED IN THIS ISSUE

CIRCLE THE APPROPRIATE NUMBER ON READER SERVICE CARD OPPOSITE

EQUIPMENT CIRCLE

ADVERTISER /SERVICE NO.

ACTION THREADED PRODUCTS . . . THREADED PRODUCTS 121

ADAMS & PORTER INSURANCE 207

ADVANCED STRUCTURES PANELS/DOORS 245/246

ALLISON GAS TURBINE/DIV. GM . . . GAS TURBINES 350

CANTIRI NAVALI SHIPBUILDING 181

CAL-VAL CO FIRE CONTROL 120

CMC COMMUNICATIONS COMMUNICATIONS 130

COLT INDUSTRIES DIESEL ENGINES 182

COOPER INDUSTRIES ENGINE MONITORING 287

CRAWFORD/CAJON TUBE FITTINGS 140

ENERJEE LTD WELDING FILTERS 109

ENGELHARD CORROSION COATING 250

FMC COFFIN TURBO PUMPS TURBO PUMP PARTS 346

R.W. FERNSTRUM GRIDCOOLERS 273

FRED DEVINE . . . . TOWING/SALVAGE SERVICE 212

FRITZ CULVER SEWAGE EJECTORS 174

GOLAR METAL A/S INCINERATORS 324

HBC BARGE BARGE BUILDERS 277

EQUIPMENT CIRCLE

ADVERTISER /SERVICE NO.

HELESHAW HYDRAULICS 302

HITACHI-ZOSEN SHIPBUILDING/REPAIR 150

LIPS PROPELLERS PROPELLERS 116

MCALLISTER TOWING/TRANSPORTATION 313

MARKEY MACHINERY DECK MACHINERY 301

MARKISCHES WERK DIESEL ENGINE PARTS 270

NATIONAL MARINE SERVICE MARINE REPAIR 310

NAV-COM COMMUNICATIONS 180

NEWPORT NEWS SHIPBUILDING .... VESSEL CONSTRUCTION/REPAIR 166

PEARLSON SHIP REPAIR/SHIPLIFT 282

PORT OF GALVESTON SHIPPING 168

THOMSON GORDON BEARINGS 311

TRIMBLE NAVIGATION NAVIGATION 330

RAMPMASTER GANGWAYS 243

SIGMA OIL/WATER SEPARATORS 231

TRANSAMERICA DELAVAL MARINE EQUIPMENT 201/202

WORLD MARINE TRANSPORT & SALVAGE ... .TRANSPORT & SALVAGE 220

G.J. WORTELBOER ANCHORS/WINCHES/CHAINS 321

Koch-Ellis Pioneers

Aerobic Digesting Systems

In Wash Water Treatment —Data Available

Koch-Ellis Barge and Ship Ser- vice has been pioneering a new pro- gram of aerobic digesting systems for on-sight treatment of wash water. Koch-Ellis has worked close- ly with the Environmental Protec- tion Agency to help set industry waste disposal standards.

The process of aerobic digesting systems sounds at first like bacteria working out, while eating every- thing. This is partially correct.

This new form of generic technol- ogy takes its idea from the old use of the septic tank for waste disposal.

Bacteria in the septic tank disinte- grates raw sewage.

Scientists created bacteria that consumed oil, which petroleum companies use as a final tank clean- ing method.

Now Koch-Ellis, working closely with the EPA, is using aerobic di- gesting systems in its treatment of wash water from the cleaning of barges and ships that carry petro- leum products, chemicals and edi- bles.

The slurry of wash water leftover after ship or barge cleaning is first put through a clarifier process that separates and recaptures usually 98 percent of the chemicals or oil from the wash water. The problem was that there was some residue left over, plus the wash water lacked oxygen to support life. In the past, the clarified slurry was just dumped.

Koch-Ellis's environmental con- sultant suggested aerobic digesting as a method of cleaning and adding oxygen to the water.

Leftover wash water is placed in a special tank with five separate types of bacteria genetically programmed to consume chemical and petroleum waste. Oxygen is added to keep the bacteria alive and replenish oxygen in the water.

The bacteria consume the waste, sink to the bottom of the tank and clean, oxygenated water is siphoned off the top and returned to the envi- ronment.

The process is proving to be the most effective method for final wash water cleaning. In addition, the idea is simple and contributes to a safer environment.

For further information about

Koch-Ellis Barge and Ship Service and their program of aerobic digest- ing systems,

Circle 99 on Reader Service Card

Fibergrate Introduces New

Line Of Strainer Plates—

Free Literature Available

Fibergrate Corporation of Dallas,

Texas, has introduced a new prod- uct line of fiberglass reinforced plas- tic strainer plates. These FRP sea chest strainers prevent foreign ma- terials from entering the system that takes seawater into the ship for cooling, fire water, ballast, and oth- er shipboard uses.

The strainers are corrosion resis- tant to 72 different kinds of corro- sive salts, many present in seawater.

They are impact-resistant with high resilience and are unaffected by ob- jects bumping into them. Electrical- ly nonconcluctive, the FRP plates are approximately one-fourth the weight of metallic strainers and are said to cost as much as 75 percent less.

For free literature containing full information, prices, etc.,

Circle 90 on Reader Service Card

Colombo Dockyard Offers

Brochure On Facilities

And Capabilities

Colombo Dockyard (Pte) Ltd. (CDL) of Colombo, Sri Lanka, is offering a new 12-page full-color brochure on the yard's facilities and capabilities.

The text of the brochure points out that Colombo is in an ideal loca- tion, situated at the intersection of sea lanes to the east from the Medi- terranean, the Gulf, east coast of

Africa, west coast of the Indian sub- continent and the sea lanes to the west from the Bay of Bengal, Aus- tralia and the Far East. The ship- yard is located inside the Port of

Colombo, enabling repairs to be car- ried out conveniently while dis- charging cargo or at anchorage dur- ing all seasons.

CDL, after heavy investment and comprehensive modernization of ship repair facilities and workshops, is now equipped to offer competitive prices for docking of all ships up to 30,000 dwt, maintenance and repair work, conversions, and newbuilding of smaller ships.

The normal capacity, length, width, height over blocks, and cra- nage are given for Colombo's three graving docks which are capable of handling vessels up to 30,000 dwt. A 100,000-dwt graving dock is now un- der construction and is scheduled to be completed by the end of 1985.

The many types of repair and ser- vices offered by the yard are listed and explained in the brochure, and the names and addresses are given of representatives of CDL in Eng- land, Greece, Hong Kong, India,

Singapore, USA, West Germany and the Netherlands.

An outline map of Sri Lanka is included in the back of the publica- tion, showing the location of the

Colombo Dockyard. The map is cen- tered over photos that illustrate the varied and interesting attractions the island has to offer.

For further information and a free copy of the brochure from Colombo

Dockyard,

Circle 71 on Reader Service Card

Literature Offered On

Cartridge-Mounted Seal

For Viking Pumps

Cartridge-mounted Style 114

Chesterton® Seal from A.W. Ches- terton Co., Stoneham, Mass., is ex- pressly designed to convert several series and models of Viking Pumps from mechanical packing to me- chanical sealing.

Conversion is easily accomplished by removing the original pump packing and gland. The only modifi- cation needed is to machine a coun- terbore in the stuffing box face 2'Xe inches O.D. by Vs-inch deep. On sliding the 114 Seal on the shaft, the counterbore mates with the gland pilot and locates the seal onto the shaft at the proper position. No measuring, centering or adjusting of the 114 Seal is needed.

Conversion to sealing eliminates packing leakage and maintenance adjustments. Better control of slur- ry fluids is attained with a dynamic 0-ring located at the back of carbon holder, minimizing buildup of parti- cles and possible clogging of seal. A static O-ring eliminates any groov- ing or fretting of shaft. A circulating line port is included in gland for flush applications. All parts are pre- cision set in gland as single cartridge unit. There are no loose components to be mislaid or inaccurately in- stalled.

For free literature containing complete information,

Circle 81 on Reader Service Card 40 Maritime Reporter/Engineering News

37

37

39

39