Page 28: of Maritime Reporter Magazine (December 1985)

Read this page in Pdf, Flash or Html5 edition of December 1985 Maritime Reporter Magazine

IDEMITSU MARU

Ishikawajima-Harima

The 258,090-dwt, super-energy- saving very large crude carrier

Idemitsu Maru was delivered re- cently by Ishikawajima-Harima

Heavy Industries Company's Kure

Shipyard to Idemitsu Tanker Com- pany of Tokyo.

The big tanker has an overall length of 1,058 feet, beam of 196.85 feet, depth of 94.5 feet, and maxi- mum draft of about 63 feet. Propul- sion is provided by a low-speed IHI/

Sulzer 8RTA84 diesel engine with a maximum continuous rating of 23,500 bhp at 65 rpm and normal rating of 21,150 bhp at 62.5 rpm. On

Outstanding Oceangoing

Vessels of 1985 (continued)

The Siemens propulsion control system, which includes automatic main engine overload control as well as an engine load increase feature, incorporates different operating modes, including: constant-speed operating mode at 136 rpm for shaft alternator operation; and two com- bination operating modes—one thrust mode and one pitch mode— where the engine speed, propeller thrust, and propeller pitch are con- trolled according to a pre-estab- lished curve.

At sea, the ship will normally operate in the constant-speed mode at 136 rpm, and the shaft-driven alternators will feed the main switchboard. As it is not the inten- tion to run the two shaft alternators in parallel, the main switchboard is capable of being operated in a "split" mode by means of a section breaker on the bus bar. In this mode each alternator will feed half of the main switchboard.

The vessel's hull form has been developed to give good propulsion and seakeeping performance with due regard to the large propeller tip clearance requirements at the vari- ous design conditions. The lines have been designed to give the smallest possible resistance, with the bulbous bow designed for a draft of 24.6 feet and optimized for a ser- vice speed of 19.5 knots.

Except for certain parts of the public spaces, where special features are introduced, Dampa continuous ceiling systems consisting of pre- stressed, baked enamel, steel/alumi- num panels, are used throughout the accommodations. Sound-ab- sorbing decks consisting of mineral wool slabs with steel tops are in- stalled in the crew accommodations above the engine rooms as well as below the bandstand and dance

HOLIDAY

Major Suppliers

Main engines (2) Sulzer

Engine controls Siemens

Propellers (2) & thrusters (4) KaMeWa

Steering gear Frydenbo

Stabilizers . . . HDW

Alternators (5) Siemens

Alternator diesels (3) . . Wartsila-Vasa

Power takeoffs (2)

Lohmann & Stolterfoth

Switchboards Merlin Gerin

Oil-fired boilers (2) Aalborg

Distilling plant Atlas

Air conditioning plant Semco

Compressors McQuay

Sprinkler & alarm system . . . Semco

Halon system Wormald

Deck machinery Norwinch

Anchors SPEK

Side doors Aalborg

Watertight doors Schroder

Windows Harndrup

Elevators Dan

Lifeboats Harding

Life rafts Nordisk

Radars (3), Loran C, facsimile recorder, speed log ... .Raytheon

SatNav system Magnavox

Radio direction finder Furuno

Gyrocompass, autopilot, & magnetic compass Plath

Steering controls, rudder indicator EMRI

Communications equipment . . .Sailor

TV & PA systems Phillips

Coatings International floors to provide maximum insula- tion against noise.

The Holiday is a typical example of the ships produced by the Ship

Division of Aalborg Vaerft—a high- ly complex passenger vessel of the most advanced design and compris- ing the latest technology, purpose- built to insure full compatability with the requirements of the own- er.

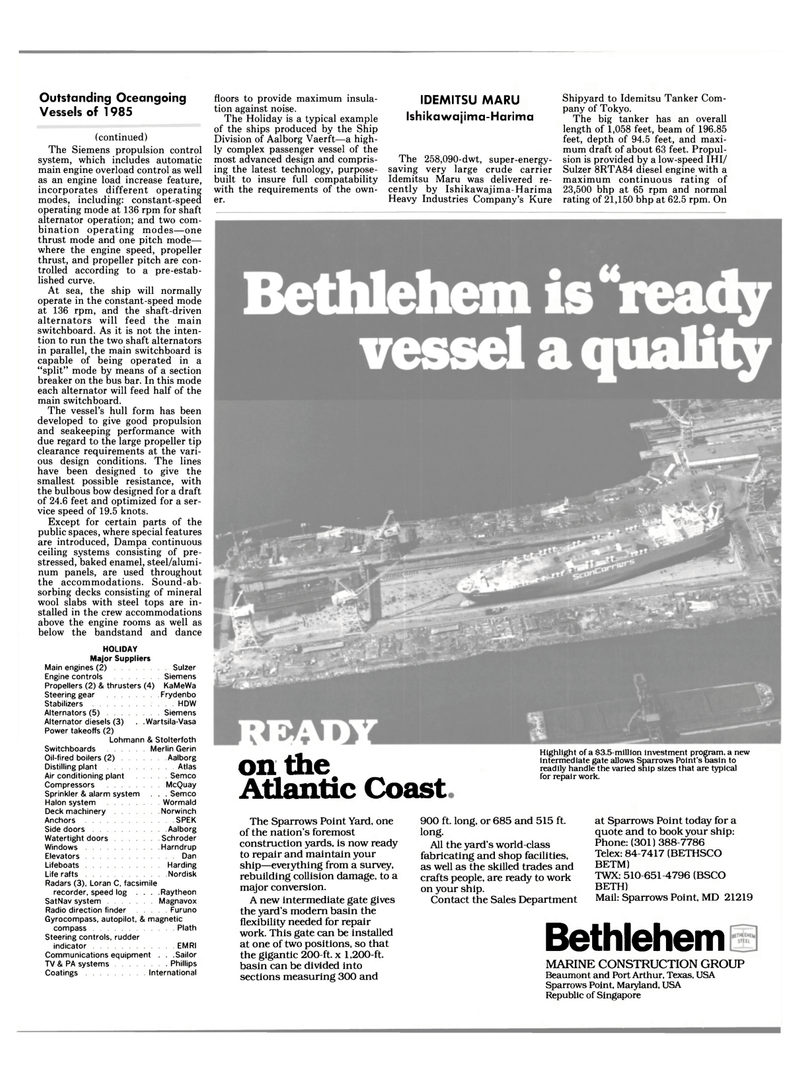

The Sparrows Point Yard, one of the nation's foremost construction yards, is now ready to repair and maintain your ship—everything from a survey, rebuilding collision damage, to a major conversion.

A new intermediate gate gives the yard's modern basin the flexibility needed for repair work. This gate can be installed at one of two positions, so that the gigantic 200-ft. x 1,200-ft. basin can be divided into sections measuring 300 and 900 ft. long, or 685 and 515 ft. long.

All the yard's world-class fabricating and shop facilities, as well as the skilled trades and crafts people, are ready to work on your ship.

Contact the Sales Department at Sparrows Point today for a quote and to book your ship:

Phone: (301) 388-7786

Telex: 84-7417 (BETHSCO

BETM)

TWX: 510-651-4796 (BSCO

BETH)

Mail: Sparrows Point, MD 21219

Bethlehem

MARINE CONSTRUCTION GROUP

Beaumont and Port Arthur, Texas, USA

Sparrows Point, Maryland, USA

Republic of Singapore

Highlight of a $3.5-million investment program, a new intermediate gate allows Sparrows Point's basin to readily handle the varied snip sizes that are typical for repair work. on the Atlantic Coast

27

27

29

29