Page 49: of Maritime Reporter Magazine (December 1985)

Read this page in Pdf, Flash or Html5 edition of December 1985 Maritime Reporter Magazine

from 54 to almost 70 feet. Doing this also required the alteration of three existing decks.

These modifications provided more cargo holds, space for a third set of twin Hagglunds 36-ton-capac- ity cranes, and a new 80-man deck- house for "surge" crews needed dur- ing periodic loading and unloading.

The normal crew complement will be about 65, comprised of civilian and MSC Personnel.

Other major additions included new ramps, fuel tanks, repair shops, and a helicopter landing platform aft. Reconstruction statistics, with the new 755-foot overall length and 69-foot 10'/2-inch depth, include a displacement of 28,249 long tons and a 32-foot lOVa-inch full-load draft.

The ship's Sulzer diesel engine propulsion plant, a 7RND76M with a maximum continuous rating of 15,960 bhp at 112 rpm, will provide a service speed of 17.5 knots operat- ing at 85 percent of mcr.

On-board capacities include 120,000 square feet for vehicles, space for 313 ammunition and re- frigerated cargo containers, 1.3 mil- lion gallons of drummed and bulk petroleum products, 84,933 gallons of potable water, and 615,083 gal- lons of fuel oil.

USNS REGULUS

National Steel

The San Diego yard of National

Steel and Shipbuilding Company recently redelivered the USNS Reg- ulus (T-AKR-292), a Fast Supply

Ship converted for the U.S. Navy's

Military Sealift Command. She and her sister ships are among the larg- est and fastest cargo vessels in the world, with an overall length of 946 feet and speed of 33 knots. The T-

AKRs will be contract-operated by civilian mariners, and held in ready reserve status until needed for con- tingencies or used in Department of

Defense exercises.

These supply ships are former

Sea-Land SL-7 containerships that will provide rapid sealift capability for the transport of military equip- ment and supplies from the U.S. to any part of the world. They are being converted to give them: roll- on/roll-off capability via MacGre- gor-Navire access equipment; self- sustaining cargo-handling capabili- ty using new 35-ton and 50-ton twin cranes supplied by Hagglunds; an emergency helicopter landing area; and side ports to facilitate rapid loading and discharge.

The Military Sealift Command is responsible for providing the neces- sary sealift capability to rapidly supply military forces overseas and sustain them for as long as opera- tional requirements dictate. The

MSC also operates auxiliary ships that deliver supplies to Navy com- batant ships while underway, ocean- ographic and survey vessels, and tankers and dry cargo vessels that deliver Defense Department cargoes worldwide.

Bender Shipbuilding Wins $4.5 Million In Contracts

Bender Shipbuilding & Repair

Co., Inc., Mobile, Ala., has been awarded a $1.292-million contract by the U.S. Navy for the conversion and regular overhaul of YFU-79 (self-propelled harbor utility craft) to HLT-1 (helicopter landing train- er) with redelivery to the Navy in

March 1986. Some of the modifica- tions include having the bow ramp welded in the closed position and operating equipment removed, all asbestos removed, and the pilot- house and accommodations located aft are to be modified and relocated forward.

In addition, Bender has been awarded a $3.2-million contract by the U.S. Army Corps of Engineers,

Vicksburg District, for the major conversion from steam powered to

SCR diesel-electric to the dredge

Jadwin. The routine overhaul and maintenance work will be per- formed concurrently. The duration of this project will be approximately six months.

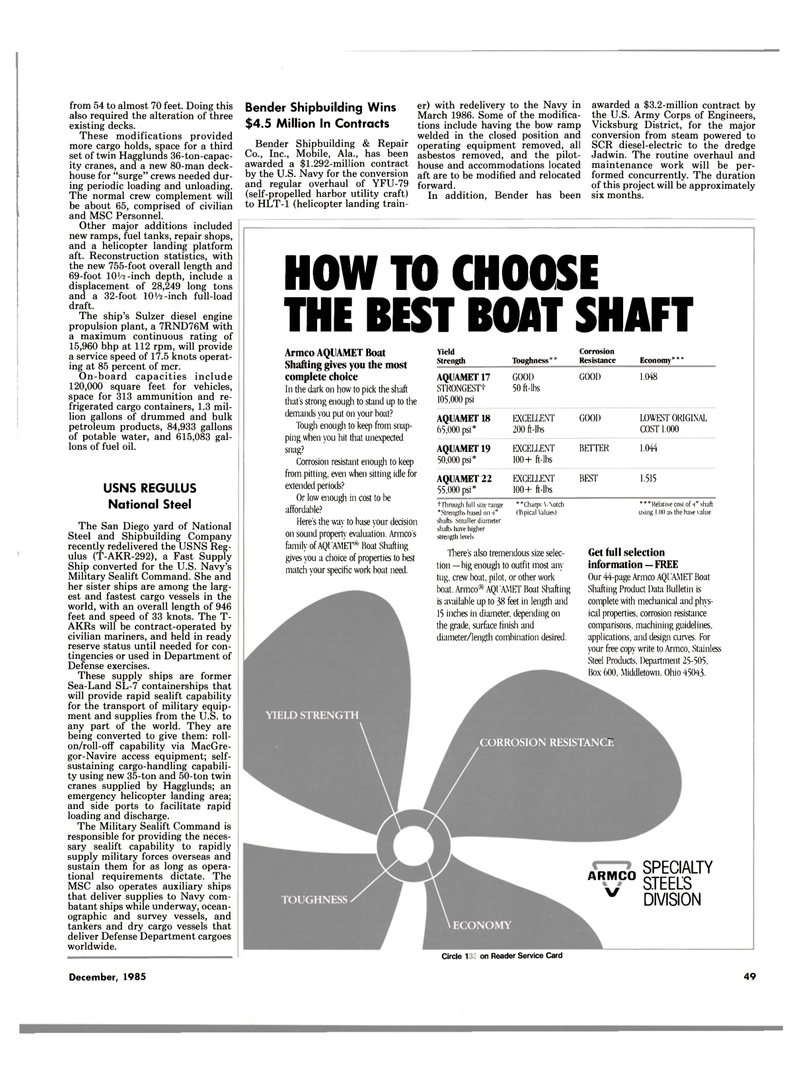

HOW TO CHOOSE THE BEST BOAT SHAFT

Armco AQUAMET Boat

Shafting gives you the most complete choice

In the dark on how to pick the shaft that's strong enough to stand up to the demands you put on your boat?

Tough enough to keep from snap- ping when you hit that unexpected snag?

Corrosion resistant enough to keep from pitting, even when sitting idle for extended periods?

Or low enough in cost to be affordable?

Here's the way to base your decision on sound property evaluation. Armco's family of AQUAMET® Boat Shafting gives you a choice of properties to best match your specific work boat need.

Yield Corrosion

Strength Toughness** Resistance Economy***

AQUAMET 17

STRONGEST! 105,000 psi

GOOD 50 ft-lbs

GOOD 1.048

AQUAMET 18 65,000 psi*

EXCEI1ENT 200 ft-lbs

GOOD LOWEST ORIGINAL

COST 1.000

AQUAMET 19 50,000 psi*

EXCELLENT 100+ ft-lbs

BETTER 1.044

AQUAMET 22 55,000 psi*

EXCELLENT 100+ ft-lbs

BEST 1.515 tTh rough full size range * Strengths based on 4" **Charp\ \-\otch (TVpical Values) **'Relative cost of V shaft using 1.00 as the base value shafts. Smaller diameter shafts have higher strength levels

There's also tremendous size selec- tion — big enough to outfit most any tug, crew boat, pilot, or other work boat. Armco® AQUAMET Boat Shafting is available up to 38 feet in length and 15 inches in diameter, depending on the grade, surface finish and diameter/length combination desired.

CORROSION RESISTANCE

Get full selection information — FREE

Our 44-page Armco AQUAMET Boat

Shafting Product Data Bulletin is complete with mechanical and phys- ical properties, corrosion resistance comparisons, machining guidelines, applications, and design curves. For your free copy write to Armco, Stainless

Steel Products, Department 25-505,

Box 600, Middletown, Ohio 45043.

ARMCO SPECIALTY STEELS v DIVISION

Circle 169 on Reader Service Card

December, 1985 49

48

48

50

50