Page 21: of Maritime Reporter Magazine (January 1986)

Read this page in Pdf, Flash or Html5 edition of January 1986 Maritime Reporter Magazine

Main engines (2) . . . . . Deutz KHD

Reduction gears . . .Philadelphia Gear

Propellers Lips

Shaft bearings .... . . Waukesha

Steering system . . . .... Wagner

Bow thruster .... . . . Schottel

ECR & bridge consoles .... Continental Electric

Dredge console . . . .... Noltec

Generators . . Caterpillar

Hydraulic system . . . . . .Rexroth

Ventilation fans . . . . . . . Hartzell

Ventilation cowls . . Winel

Switchboards .... General Electric

Dredge instrumentation . . Observator

Dredge pump & jet pump Mobile Pulley

Pumps Ingersoll Rand,

M.P. Pumps & Roper

Wastewater treatment . . .Omnipure

Bilge o/w separator . Hyde Products

Fuel oil purifier . . . . . . Alfa-Laval

Plate cooler .... Tranter

Deck cranes . . . Appleton

Winches Intercontinental

Halon system .... . . Chemetron and delivered to Gulf Coast Trailing

Company of Kenner, La., a joint venture of T.L -James & Company,

Hollandsche Aanneming Maat- schappy, and Dredging Internation- al.

The new dredge has a BP length of 278 feet, beam of 55 feet, depth of 24.5 feet, and draft of about 21.3 feet. Main propulsion is provided by two Deutz KHD S/BV16M628 die- sels, each rated 4,270 bhp at 1,000 rpm, driving Lips propellers via

Philadelphia Gear reduction gears.

A Schottel bow thruster is installed to enhance maneuvering. The steer- ing system was supplied by Wagner

Engineering, and shaft bearings by

Waukesha. Caterpillar generators provide electric power.

Designed by TCS, the Ouachita was constructed using the latest modular and zone construction techniques. Modules weighing up to 125 tons are fabricated in the yard's large erection hall, moved out by hydraulic walkers, and lifted into place using a heavy-lift Ring Horse crane.

Twin City has become one of the leading U.S. shipyards in the design and construction of hopper dredges and dump scows, in addition to its standard line of hopper barges, deck barges, and Portabarges™.

RACE POINT

Eastern Marine

Eastern Marine, Inc. of Panama

City, Fla., recently delivered the passenger/vehicle ferry Race Point to the Fishers Mand Ferry District,

Fishers Island, N.Y. Designed by the naval architecture and marine engineering firm of SAS Designers in Mobile, the ferry has an overall length of 162 feet, beam of 33 feet, depth of about 10 feet, and loaded draft of approximately 7.5 feet.

The Race Point is powered by twin Caterpillar 3412T diesel en- gines each with an output of 540 bhp at 1,800 rpm, driving Colum- bian propellers via Twin Disc MG 518 reverse/reduction gears and

Armco Aquamet 22 stainless steel propeller shafts. Two PSI bow thrusters are driven by Detroit 6-71 diesels. Electric power is produced by two 20-kw generators powered by

Detroit 2-71 engines.

The vessel will operate primarily between Fishers Island and New

London, Conn, in all types of weath- er. She meets all the applicable reg- ulations of the U.S. Coast Guard, the Public Health Service, and the

Environmental Protection Adminis- tration, as well as New York State rules for operation on lakes, bays, and sounds. The ferry has a capacity of four 35-ton trucks or a mixture of smaller trucks and cars, and a maxi- mum of 250 passengers. Diesel fuel capacity is 10,000 gallons, and 500 gallons of fresh water. Speed when half loaded is approximately 11 knots.

Eastern Marine is engaged in the design and construction of cruise (continued)

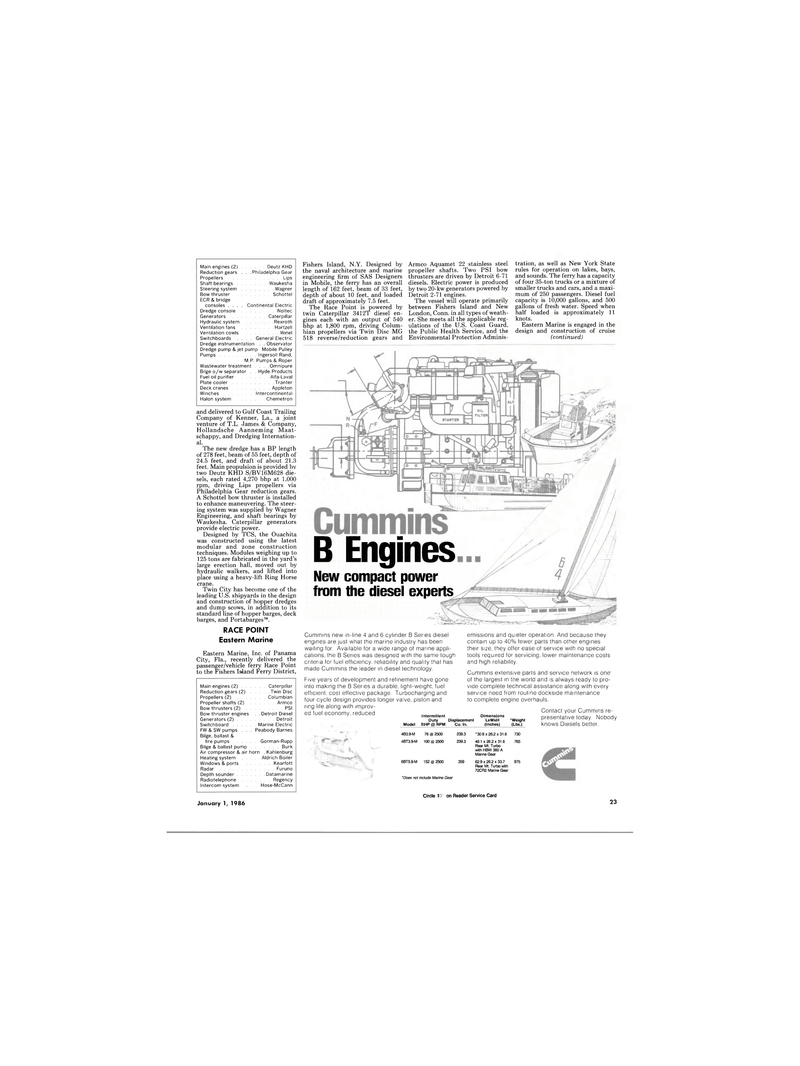

B Engines

New compact power from the diesel experts

Main engines (2) . . . . . . Caterpillar

Reduction gears (2) .... Twin Disc

Propellers (2) . . . . . . . Columbian

Propeller shafts (2) Armco

Bow thrusters (2) . . PSI

Bow thruster engines . . Detroit Diesel

Generators (2) ... . Detroit

Switchboard . Marine Electric

FW & SW pumps . . . Peabody Barnes

Bilge, ballast & fire pumps Gorman-Rupp

Bilge & ballast pump . Burk

Air compressor & air horn . Kahlenburg

Heating system . . . . . Aldrich Boiler

Windows & ports . . .... Kearfott

Radar Furuno

Depth sounder . . . . , . .Datamarine

Radiotelephone . . .... Regency

Intercom system . Hose-McCann

Cummins new in-line 4 and 6 cylinder B Series diesel engines are just what the marine industry has been waiting for. Available tor a wide range of marine appli- cations, the B Series was designed with the same tough criteria for fuel efficiency, reliability and quality that has made Cummins the leader in diesel technology.

Five years of development and refinement have gone into making the B Series a durable, light-weight, fuel efficient, cost effective package, Turbocharging and four cycle design provides longer valve, piston and ring life along with improv- ed fuel economy, reduced emissions and quieter operation. And because they contain up to 40% fewei parts than other engines their size, they offer ease of service with no special tools required for servicing, lower maintenance costs and high reliability,

Cummins extensive parts and service network is one' of the largest in the world and is always ready to pro- vide complete technical assistance along with every service need from routine dockside maintenance to complete engine overhauls.

Model

Intermittent

Duty Displacement

BHP @ RPM Cu. In.

Dimensions

LxWxH (Inches) •Weight (Lbs.)

Contact your Cummins re- presentative today. Nobody knows Diesels better, 4B3.9-M 76 @ 2500 239.3 4BT3.9-M 100 @ 2500 239.3 6BT5.9-M 152 @ 2500 359 'Does not include Marine Gear •30.8 x 26.2 x 31,6 49.1 x 26.2 x 31.6

Rear Mt. Turbo with HBW 360 A

Marine Gear 62.9 x 26.2 x 33.7

Rear Mt. Turbo with 72CR2 Marine Gear 730 765 975

Circle 158 on Reader Service Card 23 January 1, 1986

20

20

22

22