Page 9: of Maritime Reporter Magazine (February 1986)

Read this page in Pdf, Flash or Html5 edition of February 1986 Maritime Reporter Magazine

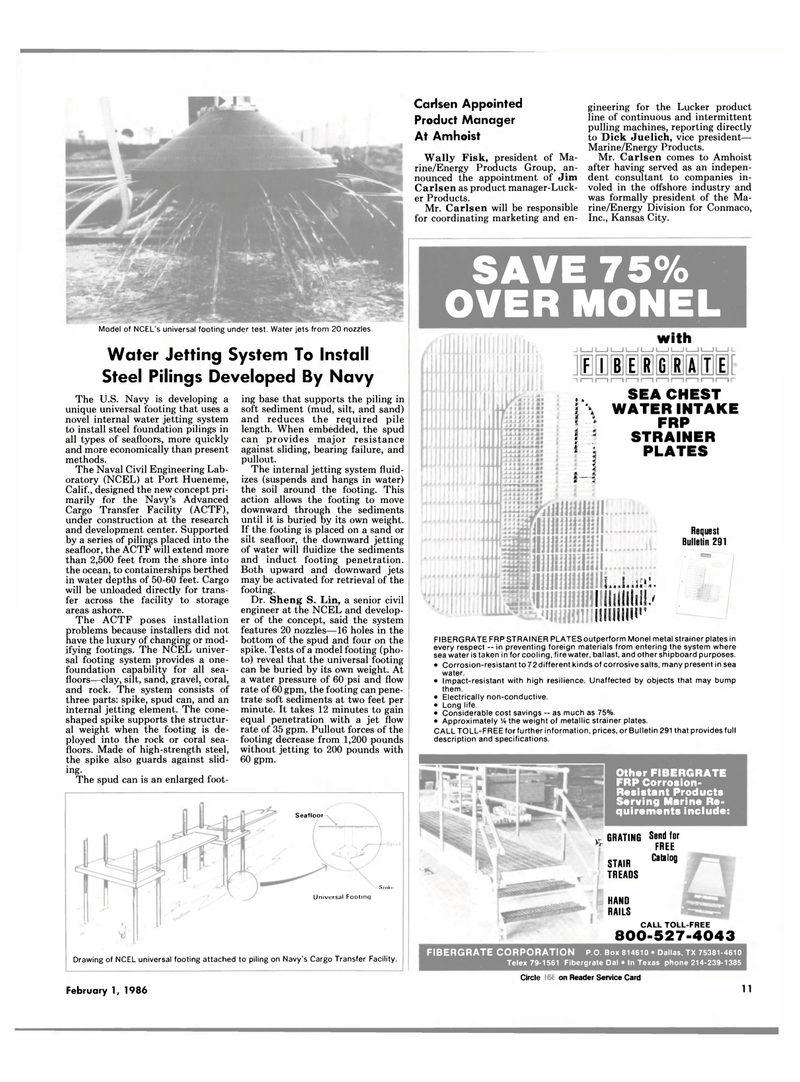

Model of NCEL's universal footing under test. Water jets from 20 nozzles

Carlsen Appointed

Product Manager

At Amhoist

Wally Fisk, president of Ma- rine/Energy Products Group, an- nounced the appointment of Jim

Carlsen as product manager-Luck- er Products.

Mr. Carlsen will be responsible for coordinating marketing and en- gineering for the Lucker product line of continuous and intermittent pulling machines, reporting directly to Dick Juelich, vice president—

Marine/Energy Products.

Mr. Carlsen comes to Amhoist after having served as an indepen- dent consultant to companies in- voled in the offshore industry and was formally president of the Ma- rine/Energy Division for Conmaco,

Inc., Kansas City.

SAVE 75%

OVER MONEL

Water Jetting System To Install

Steel Pilings Developed By Navy

The U.S. Navy is developing a unique universal footing that uses a novel internal water jetting system to install steel foundation pilings in all types of seafloors, more quickly and more economically than present methods.

The Naval Civil Engineering Lab- oratory (NCEL) at Port Hueneme,

Calif., designed the new concept pri- marily for the Navy's Advanced

Cargo Transfer Facility (ACTF), under construction at the research and development center. Supported by a series of pilings placed into the seafloor, the ACTF will extend more than 2,500 feet from the shore into the ocean, to containerships berthed in water depths of 50-60 feet. Cargo will be unloaded directly for trans- fer across the facility to storage areas ashore.

The ACTF poses installation problems because installers did not have the luxury of changing or mod- ifying footings. The NCEL univer- sal footing system provides a one- foundation capability for all sea- floors—clay, silt, sand, gravel, coral, and rock. The system consists of three parts: spike, spud can, and an internal jetting element. The cone- shaped spike supports the structur- al weight when the footing is de- ployed into the rock or coral sea- floors. Made of high-strength steel, the spike also guards against slid- ing.

The spud can is an enlarged foot- ing base that supports the piling in soft sediment (mud, silt, and sand) and reduces the required pile length. When embedded, the spud can provides major resistance against sliding, bearing failure, and pullout.

The internal jetting system fluid- izes (suspends and hangs in water) the soil around the footing. This action allows the footing to move downward through the sediments until it is buried by its own weight.

If the footing is placed on a sand or silt seafloor, the downward jetting of water will fluidize the sediments and induct footing penetration.

Both upward and downward jets may be activated for retrieval of the footing.

Dr. Sheng S. Lin, a senior civil engineer at the NCEL and develop- er of the concept, said the system features 20 nozzles—16 holes in the bottom of the spud and four on the spike. Tests of a model footing (pho- to) reveal that the universal footing can be buried by its own weight. At a water pressure of 60 psi and flow rate of 60 gpm, the footing can pene- trate soft sediments at two feet per minute. It takes 12 minutes to gain equal penetration with a jet flow rate of 35 gpm. Pullout forces of the footing decrease from 1,200 pounds without jetting to 200 pounds with 60 gpm.

FIBERGRATE FRP STRAINER PLATESoutperform Monel metal strainer plates in every respect — in preventing foreign materials from entering the system where sea water is taken in for cooling, fire water, ballast, and other shipboard purposes. • Corrosion-resistant to 72different kinds of corrosive salts, many present in sea water. • Impact-resistant with high resilience. Unaffected by objects that may bump them. • Electrically non-conductive. • Long life. • Considerable cost savings — as much as 75%. • Approximately '/< the weight of metallic strainer plates.

CALL TOLL-FREE for further information, prices, or Bulletin 291 that provides full description and specifications.

Other FIBERGRATE

FRP Corrosion-

Resistant Products

Serving Marine Re- quirements include:

GRATING Send for hi FREE

STAIR Catal0fl

TREADS

HAND

RAILS

CALL TOLL-FREE 800-527-4043

Seafloor

Sink.-

Universal Footing of NCEL universal footing attached to piling on Navy's Cargo Transfer Facility. Drawing with

F 1 B E R G R A T E $ j. SEA CHEST > . « » # * WATER INTAKE i k % * FRP i,. :S * STRAINER f ' 1 1 5

PLATES

I i | t • j * IsiisiJU .»!»*-*•< . Illllllil!.'

IIIIIIIIU1'

Request

Bulletin 291

FIBERGRATE CORPORATION P.O. Box 814610 • Dallas, TX 75381-4610

Telex 79-1561 Fibergrate Dal • In Texas phone 214-239-1385

February 1, 1986

Circle 240 on Reader Service Card 11

8

8

10

10