Page 38: of Maritime Reporter Magazine (February 1986)

Read this page in Pdf, Flash or Html5 edition of February 1986 Maritime Reporter Magazine

PROPULSION UPDATE

The New 710G Series

Diesel Engines From General Motors

Electro-Motive Division

By Hugh Williams Jr.* (Ed. note—Complete literature is now available from GM/EMD describing the new 710G Series.)

The new 710G Series of diesel engines from General Motors Elec- tro-Motive Division (GM/EMD) of- fers increased reliability, better fuel efficiency, and the potential for sig- nificantly higher horsepower in the future. This design is an evolution- ary development of GM/EMD's tur- bocharged, uniflow scavenged, two- stroke cycle engine, which retains the latter's historical simplicity of design, maintainability, and high re- liability.

The 16-cylinder diesel is rated conservatively at 3,600 horsepower at 900 rpm for marine applications, and has a displacement of 710 cubic inches per cylinder. GM/EMD will market models of this new series of engines for a variety of applica- tions.

The design of the 710G is a logical outgrowth of GM/EMD's current production series, the 645F engines.

ENGINE SPECIFICATIONS 16-645FB 16-710G

Bore in. 9.06 9.06

Stroke in. 10 11

Displacement in. 645 710

Cylinder Spacing in. 16% 16%

Bank Angle 45 45

Compression Ratio 16.01:1 16.01:1

Engine Speed rpm 900 900

BHP (marine rating) 3,400 3,600

Table 1. This table compares the specifica- tions of GM/EMD's new 710G diesel with its predecessor, the 645FB.

The most recent version of this series, the 645FB, is the result of a succession of incremental improve- ments to the engine. From 1980 to 1983, for example, the fuel efficien- cy of the 645F was increased by 6 percent and the compression ratio was increased from 14.5:1 to 16:1.

Similarly, the 710G can be viewed as a new dimension in engine design, in terms of its potential for future growth. (Table 1 is a comparison of specifications.) Greater displace- ment and an advanced turbocharger give the 710G the capacity for sig- nificant increases in horsepower.

Thus, the 710G combines innova- tion with the proven technology of its predecessor, but its potential makes it more than just this year's model.

The 710G is the product of exten- sive development at GM/EMD. To- tal development cost was $60 mil- lion. Tooling cost alone was $78 mil- lion.

Fuel Efficiency

The 710G is GM/EMD's most fuel-efficient diesel to date. Full load fuel consumption of the Model 710G engine has been improved by 9 percent from the 1980 Model 645F3 engine.

Displacement

A major change in the 710G de- sign is greater displacement. The 10-inch piston stroke of the prede- cessor 645FB was increased to 11 inches in the 710G engine. The long- er stroke at the same bore adds 10

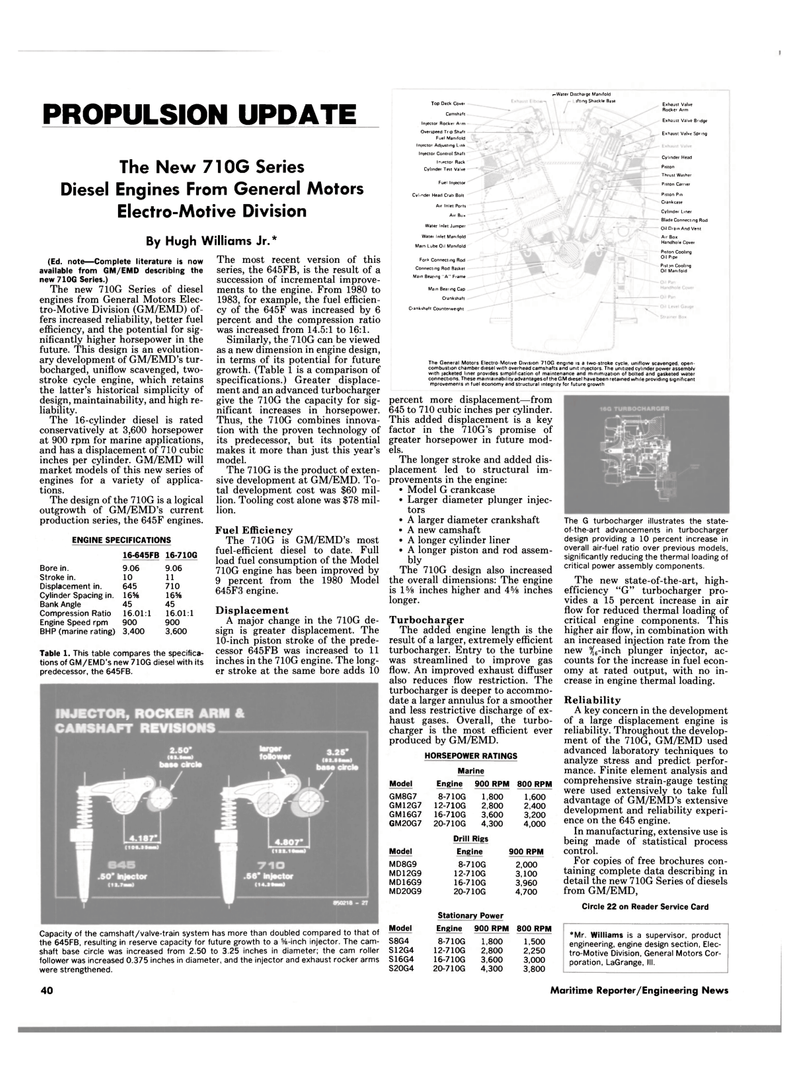

Capacity of the camshaft/valve-train system has more than doubled compared to that of the 645FB, resulting in reserve capacity for future growth to a %-inch injector. The cam- shaft base circle was increased from 2.50 to 3.25 inches in diameter; the cam roller follower was increased 0.375 inches in diameter, and the injector and exhaust rocker arms were strengthened.

Marine

Model

GM8G7

GM12G7

GM16G7

GM20G7

Model

MD8G9

MD12G9

MD16G9

MD20G9

Model

S8G4

S12G4

S16G4

S20G4

Engine 8-710G 12-710G 16-710G 20-710G 900 RPM 800 RPM 1,800 2,800 3,600 4,300 1,600 2,400 3,200 4,000

Drill Rigs

Engine 8-710G 12-710G 16-710G 20-710G

Stationary Power

Engine 8-710G 12-710G 16-710G 20-710G 900 RPM 2,000 3,100 3,960 4,700 900 RPM 800 RPM percent more displacement—from 645 to 710 cubic inches per cylinder.

This added displacement is a key factor in the 710G's promise of greater horsepower in future mod- els.

The longer stroke and added dis- placement led to structural im- provements in the engine: • Model G crankcase • Larger diameter plunger injec- tors • A larger diameter crankshaft • A new camshaft • A longer cylinder liner • A longer piston and rod assem- bly

The 710G design also increased the overall dimensions: The engine is lVs inches higher and 4% inches longer.

Turbocharger

The added engine length is the result of a larger, extremely efficient turbocharger. Entry to the turbine was streamlined to improve gas flow. An improved exhaust diffuser also reduces flow restriction. The turbocharger is deeper to accommo- date a larger annulus for a smoother and less restrictive discharge of ex- haust gases. Overall, the turbo- charger is the most efficient ever produced by GM/EMD.

HORSEPOWER RATINGS

The G turbocharger illustrates the state- of-the-art advancements in turbocharger design providing a 10 percent increase in overall air-fuel ratio over previous models, significantly reducing the thermal loading of critical power assembly components.

The new state-of-the-art, high- efficiency "G" turbocharger pro- vides a 15 percent increase in air flow for reduced thermal loading of critical engine components. This higher air flow, in combination with an increased injection rate from the new 9/6-inch plunger injector, ac- counts for the increase in fuel econ- omy at rated output, with no in- crease in engine thermal loading.

Reliability

A key concern in the development of a large displacement engine is reliability. Throughout the develop- ment of the 710G, GM/EMD used advanced laboratory techniques to analyze stress and predict perfor- mance. Finite element analysis and comprehensive strain-gauge testing were used extensively to take full advantage of GM/EMD's extensive development and reliability experi- ence on the 645 engine.

In manufacturing, extensive use is being made of statistical process control.

For copies of free brochures con-taining complete data describing in detail the new 710G Series of diesels from GM/EMD,

Circle 22 on Reader Service Card 1,800 2,800 3,600 4,300 1,500 2,250 3,000 3,800 *Mr. Williams is a supervisor, product engineering, engine design section, Elec- tro-Motive Division, General Motors Cor- poration, LaGrange, III.

The General Motors Electro-Motive Division 710G engine is a two-stroke cycle, uniflow scavenged, open- combustion chamber diesel with overhead camshafts and unit injectors The unitized cylinder power assembly with jacketed liner provides simplification of maintenance and minimization of bolted and gasketed water connections These maintainability advantages of the GM diesel have been retained while providing significant mprovements in fuel economy and structural integrity for future growth

Top Deck Cover

Camshaft

Injector Rocker Arm

Overspeed Tr ip Shaft

Fuel Manifold ln|ector Adjusting Link

Injector Control Shaft

I n lector Rack

Cylinder Test Valve

Fuel Injector

Cvl-nder Heart Crab Bolt

A,r Inlet Ports

Air Bn.

Water Inlet Jumper

Water Inlet Manifold

Main Lube Oil Man fold

Forlr Connecting Rod

Connecting Rod Basket

Mam Bearing "A" Frame

Main Beaimg Cap

Crankshaft

Crankshaft Counterweight

Exhaust Valve Bridge

Exhaust Valve Spring

Cylinder Head

Piston

Thrust Washer

Piston Carrier

Piston Pin

Crankcase

Cylinder Liner

Blade Connecting Rod

OH Drain And Vent

Air Box

Handhole Cover

Prston Cooling

Oil Pipe

Piston Cooling

OH Manifold ,-Water Dischaige Manifold if11ng Shact le Base Exhaust Valve

Rocker Arm 40 Maritime Reporter/Engineering News

37

37

39

39