Page 20: of Maritime Reporter Magazine (April 1986)

Read this page in Pdf, Flash or Html5 edition of April 1986 Maritime Reporter Magazine

TECHNIC Al. DOCUMENTATION

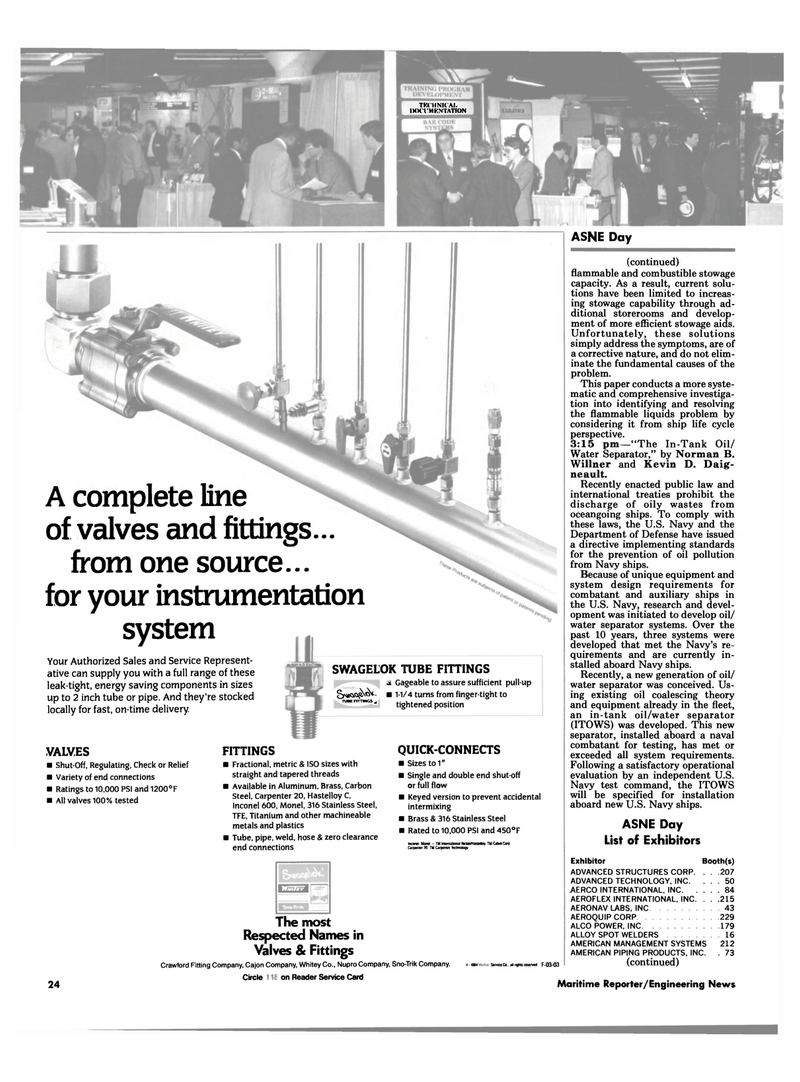

A complete line of valves and fittings... from one source... for your instrumentation system

Your Authorized Sales and Service Represent- ative can supply you with a full range of these leak-tight, energy saving components in sizes up to 2 inch tube or pipe. And they're stocked locally for fast, on-time delivery.

SWAGELOK TUBE FITTINGS • Gageable to assure sufficient pull-up gj^CkC^^- • 1-1/4 turns from finger-tight to tightened position TUBE FTrmGS^

VALVES • Shut-Off, Regulating, Check or Relief • Variety of end connections • Ratings to 10,000 PSI and 1200°F • All valves 100% tested

FITTINGS • Fractional, metric & ISO sizes with straight and tapered threads • Available in Aluminum, Brass, Carbon

Steel, Carpenter 20, Hastelloy C,

Inconel 600, Monel, 316 Stainless Steel,

TFE, Titanium and other machineable metals and plastics • Tube, pipe, weld, hose & zero clearance end connections

QUICK-CONNECTS • Sizes to 1" • Single and double end shut-off or full flow • Keyed version to prevent accidental intermixing • Brass & 316 Stainless Steel • Rated to 10,000 PSI and 450°F

Inconel. Monel - TM International t*ckeVHaste»oy. TM Cabot Corp

Carpenter 20. TM Carpenter Technology

The most

Respected Names in

Valves & Fittings

Crawford Fitting Company, Cajon Company, Whitey Co., Nupro Company, Sno-Trik Company. m ASNE Day

(continued)

flammable and combustible stowage

capacity. As a result, current solu-

tions have been limited to increas-

ing stowage capability through ad-

ditional storerooms and develop-

ment of more efficient stowage aids.

Unfortunately, these solutions

simply address the symptoms, are of

a corrective nature, and do not elim-

inate the fundamental causes of the

problem.

This paper conducts a more syste-

matic and comprehensive investiga-

tion into identifying and resolving

the flammable liquids problem by

considering it from ship life cycle

perspective.

3:15 pm—"The In-Tank Oil/

Water Separator," by Norman B.

Willner and Kevin D. Daig-

neault.

Recently enacted public law and

international treaties prohibit the

discharge of oily wastes from

oceangoing ships. To comply with

these laws, the U.S. Navy and the

Department of Defense have issued

a directive implementing standards

for the prevention of oil pollution

from Navy ships.

Because of unique equipment and

system design requirements for

combatant and auxiliary ships in

the U.S. Navy, research and devel-

opment was initiated to develop oil/

water separator systems. Over the

past 10 years, three systems were

developed that met the Navy's re-

quirements and are currently in-

stalled aboard Navy ships.

Recently, a new generation of oil/

water separator was conceived. Us-

ing existing oil coalescing theory

and equipment already in the fleet,

an in-tank oil/water separator

(ITOWS) was developed. This new

separator, installed aboard a naval

combatant for testing, has met or

exceeded all system requirements.

Following a satisfactory operational

evaluation by an independent U.S.

Navy test command, the ITOWS

will be specified for installation

aboard new U.S. Navy ships.

ASNE Day

List of Exhibitors

Exhibitor Booth(s)

ADVANCED STRUCTURES CORP. . . .207

ADVANCED TECHNOLOGY, INC. ... 50

AERCO INTERNATIONAL, INC 84

AEROFLEX INTERNATIONAL, INC. . . .215

AERONAV LABS, INC 43

AEROQUIP CORP 229

ALCO POWER, INC 17

ALLOY SPOT WELDERS 16

AMERICAN MANAGEMENT SYSTEMS 212

AMERICAN PIPING PRODUCTS, INC. . 73

(continued)

24

Circle 223 on Reader Service Card Maritime Reporter/Engineering News

19

19

21

21