Page 28: of Maritime Reporter Magazine (October 1986)

Read this page in Pdf, Flash or Html5 edition of October 1986 Maritime Reporter Magazine

Deck Machinery Review (continued) pled to the engine and provides all hydraulic power requirements. In addition, the power unit is equipped with a 120-volt, 5-kw alternator and an air compressor to make the pack- age completely self-contained.

NEUHAUS

Circle 46 on Reader Service Card

J.D. Neuhaus Hebezeuge GmbH & Company of Witten-Heven, West

Germany, manufactures a full line of pneumatic hoists, trolleys, mono- rails, and mechancial hoists with lifting capacities of up to 100 tons.

These hoists, which were developed in close cooperation with the users, are said to offer advantages that can solve lifting problems quickly and economically, particularly in the shipbuilding industry, above or be- low deck, and in the offshore sec- tor.

JDN pneumatic hoists, the stan- dard models, are suitable for appli- cation in areas where there is danger of explosion. Should increased ex- plosion protection be required, such as on offshore platforms, the hoist can be provided with higher spark- ing protection. This includes gal- vanized chain, copper-coated load hook, and brass safety catch. In trol- leys, wheels and gear wheel drive can be provided in bronze.

In comparison to their lifting ca- pacity, JDN pneumatic hoists are light and easily transportable, ro- bust; insensitive to steam, smoke, humidity, and extreme tempera- tures; need little maintenance, and are simple to operate. Lifting and lowering speeds can be regulated by rope controls. All these JDN hoist characteristics are valued by users in more than 90 countries.

PACECO

Circle 47 on Reader Service Card

The continued growth of contain- erization has resulted in the demand for container-stacking gantry cranes with increased speeds as well as higher stacking capabilities. To satisfy this need, Paceco, Inc. of

Gulfport, Miss., a pioneer in the development of such cranes for more than 25 years, has introduced a Hi-Lift/High-Speed version of its standard rubber-tired Transtainer™ crane. _0HiflB

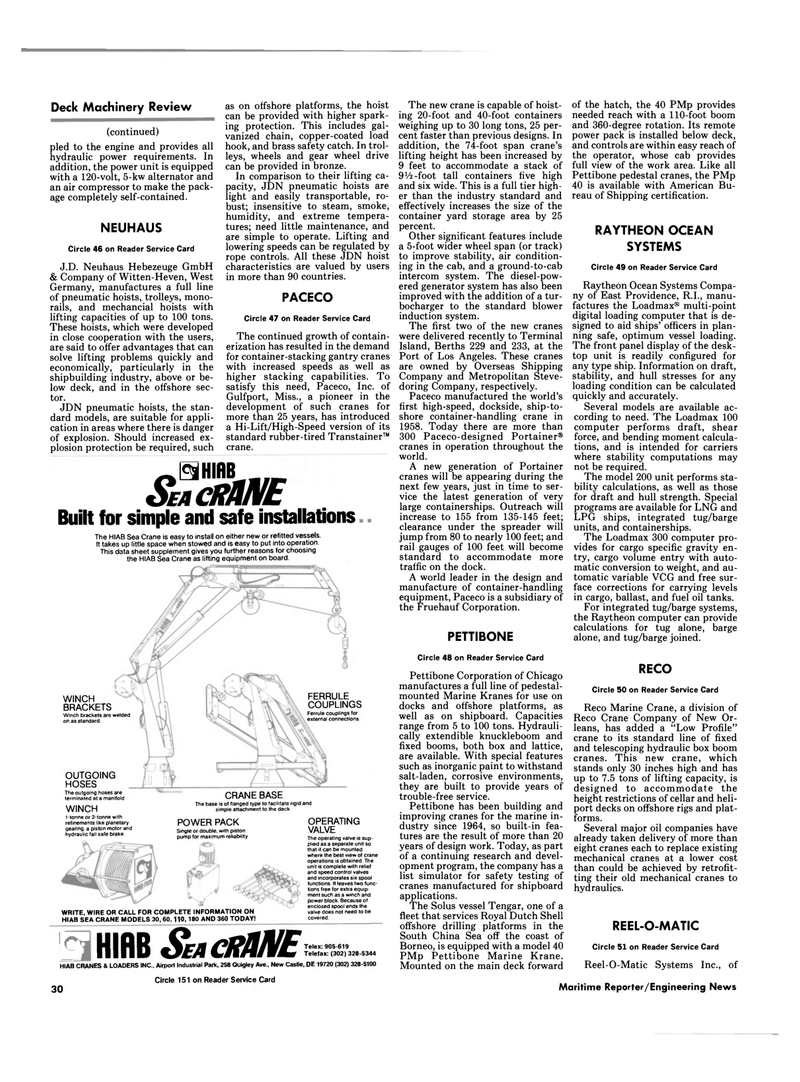

SEA CRANE

Built for simple and safe installations

The HIAB Sea Crane is easy to install on either new or refitted vessels.

It takes up little space when stowed and is easy to put into operation.

This data sheet supplement gives you further reasons for choosing the HIAB Sea Crane as lifting equipment on board.

WINCH

BRACKETS

Winch brackets are welded on as standard.

OUTGOING

HOSES

The outgoing hoses are terminated at a manifold.

FERRULE

COUPLINGS

Ferrule couplings for external connections.

WINCH

CRANE BASE

The base is of flanged type to facilitate rigid and simple attachment to the deck. 1-tonne or 2-tonne with refinements like planetary gearing, a piston motor and hydraulic fail safe brake.

POWER PACK

Single or double, with piston pump for maximum reliability

WRITE, WIRE OR CALL FOR COMPLETE INFORMATION ON

HIAB SEA CRANE MODELS 30, 60, 110,180 AND 360 TODAY!

OPERATING

VALVE

The operating valve is sup- plied as a separate unit so that it can be mounted where the best view of crane operations is obtained. The unit is complete with relief and speed control valves and incorporates six spool functions. It leaves two func- tions free for extra equip- ment such as a winch and power block. Because of enclosed spool ends the valve does not need to be covered.

E" HIAB SEA CRANE Telex: 905-619 Telefax: (302) 328-5344

HIAB CRANES & LOADERS INC., Airport Industrial Park, 258 Quigley Ave., New Castle, DE 19720 (302) 328-5100

The new crane is capable of hoist- ing 20-foot and 40-foot containers weighing up to 30 long tons, 25 per- cent faster than previous designs. In addition, the 74-foot span crane's lifting height has been increased by 9 feet to accommodate a stack of 9 V2 -foot tall containers five high and six wide. This is a full tier high- er than the industry standard and effectively increases the size of the container yard storage area by 25 percent.

Other significant features include a 5-foot wider wheel span (or track) to improve stability, air condition- ing in the cab, and a ground-to-cab intercom system. The diesel-pow- ered generator system has also been improved with the addition of a tur- bocharger to the standard blower induction system.

The first two of the new cranes were delivered recently to Terminal

Island, Berths 229 and 233, at the

Port of Los Angeles. These cranes are owned by Overseas Shipping

Company and Metropolitan Steve- doring Company, respectively.

Paceco manufactured the world's first high-speed, dockside, ship-to- shore container-handling crane in 1958. Today there are more than 300 Paceco-designed Portainer® cranes in operation throughout the world.

A new generation of Portainer cranes will be appearing during the next few years, just in time to ser- vice the latest generation of very large containerships. Outreach will increase to 155 from 135-145 feet; clearance under the spreader will jump from 80 to nearly 100 feet; and rail gauges of 100 feet will become standard to accommodate more traffic on the dock.

A world leader in the design and manufacture of container-handling equipment, Paceco is a subsidiary of the Fruehauf Corporation.

PETTIBONE

Circle 48 on Reader Service Card

Pettibone Corporation of Chicago manufactures a full line of pedestal- mounted Marine Kranes for use on docks and offshore platforms, as well as on shipboard. Capacities range from 5 to 100 tons. Hydrauli- cally extendible knuckleboom and fixed booms, both box and lattice, are available. With special features such as inorganic paint to withstand salt-laden, corrosive environments, they are built to provide years of trouble-free service.

Pettibone has been building and improving cranes for the marine in- dustry since 1964, so built-in fea- tures are the result of more than 20 years of design work. Today, as part of a continuing research and devel- opment program, the company has a list simulator for safety testing of cranes manufactured for shipboard applications.

The Solus vessel Tengar, one of a fleet that services Royal Dutch Shell offshore drilling platforms in the

South China Sea off the coast of

Borneo, is equipped with a model 40

PMp Pettibone Marine Krane.

Mounted on the main deck forward of the hatch, the 40 PMp provides needed reach with a 110-foot boom and 360-degree rotation. Its remote power pack is installed below deck, and controls are within easy reach of the operator, whose cab provides full view of the work area. Like all

Pettibone pedestal cranes, the PMp 40 is available with American Bu- reau of Shipping certification.

RAYTHEON OCEAN

SYSTEMS

Circle 49 on Reader Service Card

Raytheon Ocean Systems Compa- ny of East Providence, R.I., manu- factures the Loadmax® multi-point digital loading computer that is de- signed to aid ships' officers in plan- ning safe, optimum vessel loading.

The front panel display of the desk- top unit is readily configured for any type ship. Information on draft, stability, and hull stresses for any loading condition can be calculated quickly and accurately.

Several models are available ac- cording to need. The Loadmax 100 computer performs draft, shear force, and bending moment calcula- tions, and is intended for carriers where stability computations may not be required.

The model 200 unit performs sta- bility calculations, as well as those for draft and hull strength. Special programs are available for LNG and

LPG ships, integrated tug/barge units, and containerships.

The Loadmax 300 computer pro- vides for cargo specific gravity en- try, cargo volume entry with auto- matic conversion to weight, and au- tomatic variable VCG and free sur- face corrections for carrying levels in cargo, ballast, and fuel oil tanks.

For integrated tug/barge systems, the Raytheon computer can provide calculations for tug alone, barge alone, and tug/barge joined.

RECO

Circle 50 on Reader Service Card

Reco Marine Crane, a division of

Reco Crane Company of New Or- leans, has added a "Low Profile" crane to its standard line of fixed and telescoping hydraulic box boom cranes. This new crane, which stands only 30 inches high and has up to 7.5 tons of lifting capacity, is designed to accommodate the height restrictions of cellar and heli- port decks on offshore rigs and plat- forms.

Several major oil companies have already taken delivery of more than eight cranes each to replace existing mechanical cranes at a lower cost than could be achieved by retrofit- ting their old mechanical cranes to hydraulics.

REEL-O-MATIC

Circle 51 on Reader Service Card

Reel-O-Matic Systems Inc., of 30

Circle 151 on Reader Service Card

Maritime Reporter/Engineering News

27

27

29

29