Page 11: of Maritime Reporter Magazine (December 1986)

Read this page in Pdf, Flash or Html5 edition of December 1986 Maritime Reporter Magazine

to include a dual-pressure type ex- haust gas economizer for the turbo- generator and general service. A waste heat recovery system utilizes energy from the scavenging air cool- ers and the cylinder cooling water.

The turbo compound system, com- prising BBC gas turbine, Renk re- duction gear and automatic clutch, contributes to reduction of fuel oil consumption. The freshwater cool- ing is based on a HDW scoop and central cooler.

Highly advanced automation sys- tems are installed in the vessel. The

Damatic control system supplied by

Valmet, consisting of double CPUs and CPRs and a multi-function key- board in the engine control room console, monitors and controls all essential functions with regard to the ship's operations, starters, gen- erator power management system; controllers for pressure, tempera- ture and level; ballast, bilge, and fuel piping systems control. An en- gine control system supplied Soren

T. Lingso allows maneuvering from bridge wing consoles. External re- mote monitoring CRTs and key- boards are arranged in the wheel- house, ship's control center, and en- gineers' cabins.

In order to obtain optimum hull form and a suitable type of propel- ler, various model tests were carried out at the Norwegian Marintek lab- oratory. As a result, a barge hull form with ellipsoidal bow was adopted to minimize resistance. For increased propulsion efficiency, a skewed propeller and spoilers of

Harmstorf design (hydrodynamic fins) were fitted to the vessel.

BIRKA PRINCESS

Valmet

Valmet Corporation's Helsinki

Shipyard in Finland this year deliv- ered its first passenger ship, the Bir- ka Princess, built for Birka Line Ab of Mariehamn, Finland.

Unlike the numerous passenger/ car ferries operating in the Baltic area, the Princess is a true cruise liner. She has only a small car deck at the stern that accommodates 50 private cars and six motor coaches, or 75 cars, with access via a side ramp.

The new liner has an overall length of 469 feet, beam of 81 feet, depth to Deck 11 of 100 feet, and draft of 18.4 feet. Main propulsion is provided by four Wartsila-Vasa die- sel engines with a total output of 23,600 bhp at 750 rpm, driving two

KaMeWa controllable-pitch, highly skewed propellers via Valmet/Renk reduction gears. Cruising speed is 18 knots.

The accommodations, which pro- vide for 1,500 passengers in 500 cab- ins, are of unusually high quality.

This was achieved by detail work, careful selection of materials, unique lighting systems, and other refinements. Passengers can view the impressive Stockholm archipel- ago and the Aland Sea through spe- cial panorama windows in the a-la- carte restaurant and dancing res- taurant aft, as well as in the cocktail lounge and one of the large confer- ence rooms forward.

The principal design considera- tions for the Birka Princess were economical operation, safety, easy maintenance, and a high level of automation. Machinery is con- trolled by Valmet's Damatic ship automation system. The company's other units are also well represented among the suppliers; the Tampere

Works provided the six passenger and service elevators, and the reduc- tion gears were supplied by the

Rautpohja Works.

In cooperation with the Finnish company Rakennusvalmiste Oy,

Valmet developed a totally new cab- (continued)

CITYVARVET HAS THE

CHRISTMAS SPIRIT

Main engines (4) . . . . Wartsila-Vasa

Reduction gears (2) Valmet

Propellers (2) . . KaMeWa

Machinery control system . . . Valmet

Steering gear . . Tenfjord

Bow thruster . . KaMeWa

Stern tubes . . . .... Centromor

Auxiliary diesels . . . Wartsila-Vasa

Generators . . . . Kymi-Stromberg

Anchors .... Hollandse Constructie

Chains . . Ljusne Katting

Shaft seals .... HDW

Sewage disposal plant .... Deerberg

Vacuum toilets . . . Evac-Wartsila

Boilers, mooring winches .... . . Rauma-Repola

Air conditioning system .... Nordish Ventilator

Reefer plant for

AC system . . . .Stal Refrigeration

Air compressors . . . . .Hamworthy

Separators, heat exchangers Alfa-Laval

Valves . . .Wouter Witzel

Centrifugal pumps Maskinfabriken Iron

Oil pumps .... IMO

Lube oil filters . . . . . .Boll & Kirch

Couplings .... Vulkan

Elevators ... Valmet

December, 1986

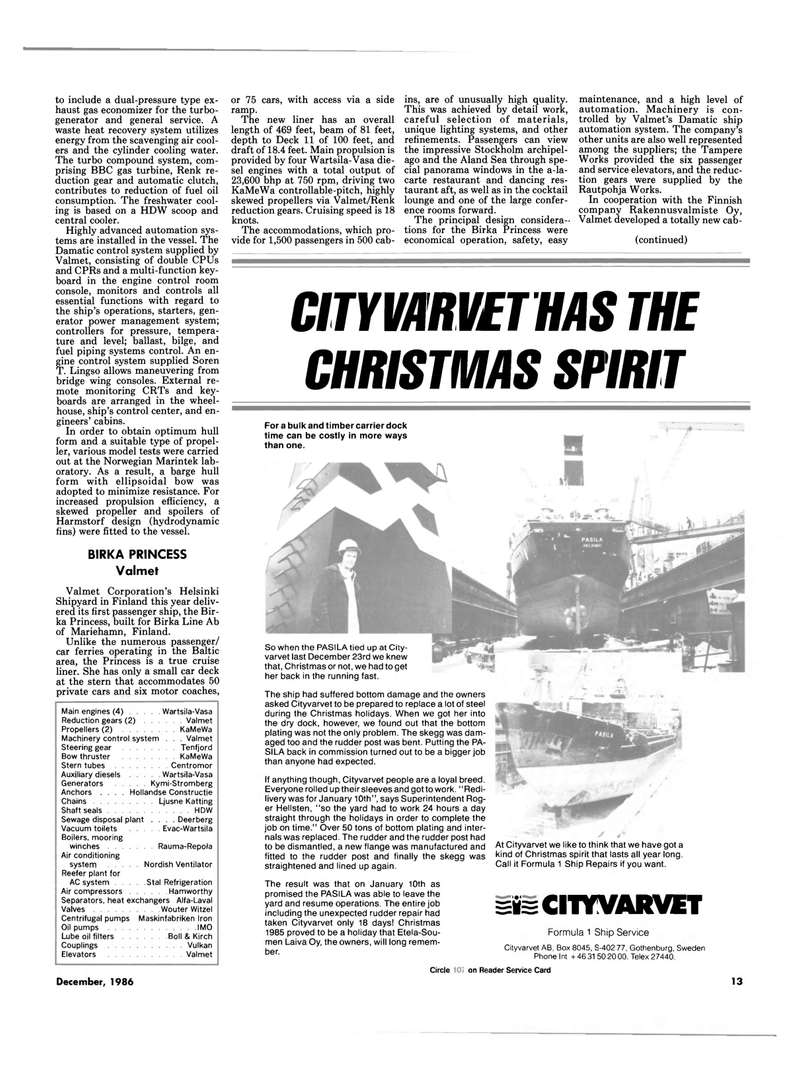

The result was that on January 10th as promised the PASILA was able to leave the yard and resume operations. The entire job including the unexpected rudder repair had taken Cityvarvet only 18 days! Christmas 1985 proved to be a holiday that Etela-Sou- men Laiva Oy, the owners, will long remem- ber. sis CITYVARVET

Formula 1 Ship Service

Cityvarvet AB, Box 8045, S-402 77, Gothenburg, Sweden

Phone Int +46 31 502000. Telex 27440.

Circle 345 on Reader Service Card 13

For a bulk and timber carrier dock time can be costly in more ways than one.

If anything though, Cityvarvet people are a loyal breed.

Everyone rolled up their sleeves and got to work. "Redi- livery was for January 10th", says Superintendent Rog- er Hellsten, "so the yard had to work 24 hours a day straight through the holidays in order to complete the job on time." Over 50 tons of bottom plating and inter- nals was replaced. The rudder and the rudder post had to be dismantled, a new flange was manufactured and fitted to the rudder post and finally the skegg was straightened and lined up again.

The ship had suffered bottom damage and the owners asked Cityvarvet to be prepared to replace a lot of steel during the Christmas holidays. When we got her into the dry dock, however, we found out that the bottom plating was not the only problem. The skegg was dam- aged too and the rudder post was bent. Putting the PA-

SILA back in commission turned out to be a bigger job than anyone had expected.

At Cityvarvet we like to think that we have got a kind of Christmas spirit that lasts all year long.

Call it Formula 1 Ship Repairs if you want.

So when the PASILA tied up at City- varvet last December 23rd we knew that, Christmas or not, we had to get her back in the running fast.

10

10

12

12