Page 50: of Maritime Reporter Magazine (February 1988)

Read this page in Pdf, Flash or Html5 edition of February 1988 Maritime Reporter Magazine

American Bureau Of Shipping—

A "Class Act' For Over 125 Years

In 1860, John D. Jones, president of the Atlantic Mutual Insurance

Company, led a group of New York

City marine insurance companies in forming a not-for-profit, benevolent purpose society to promote the safe- ty of life at sea. This evolved into the American Bureau of Shipping which developed the procedure of rating the structural and mechani- cal fitness of ships called classifica- tion.

The promotion of the safety of life and property through classification has remained the central focus of

ABS ever since. While this focus is unchanged, the knowledge, experi- ence and resources of ABS have grown. In recognition of this ad- vancement, the activities of ABS have evolved from strictly ship clas- sification into related areas. Today,

ABS and its subsidiaries of the ABS

Group of Companies, Inc. provide certification, inspection, analysis, quality assurance, and ship classifi- cation service to marine, offshore, government and industrial sectors on a worldwide basis.

The first ABS rules, those for

Building and Classing Wooden

Vessels, were published in 1870.

Since that time, ABS rules have kept pace with the developments in the shipbuilding industry, with

Rules for Building and Classing

Iron Vessels published in 1877; and

Rules for Building and Classing

Steel Vessels in 1890. These latter standards have been updated and published annually ever since.

The first half of the 1940s was a time of unprecedented growth for

ABS. From the start of World War

II through 1945, a total of 5,171

Liberty Ships, Victory Ships, T-2 tankers and various other type ves- sels were built to ABS classification as part of the Maritime Commis- sion's Wartime Shipbuilding Pro- gram. This set the stage for ABS's emergence as an international or- ganization. Following the war, ABS representation expanded through- out the world, as the government sold hundreds of ABS class surplus vessels to allies who had lost a large portion of their fleets. Today, ABS has nearly 850 exclusive surveyors and engineers stationed in 168 loca- tions around the world, on call 24- hours-a-day.

The late 1950s and early 1960s marked a significant transition peri- od for ABS and for the shipbuilding industry—a technological transi- tion. Up until that time, the primary criterion by which a ship could be classed was by comparison with sim- ilar ships proven successful in ser- vice. However, advancements in ma- rine design made it evident that a means for analyzing innovative structures was needed.

ABS responded in 1965 by partic- ipating with the University of Ari- zona and Chevron Shipping Compa- ny in a research project to develop a finite element system of programs, known as DAISY, for a computer- aided analysis of any type of vessel structure.

By the early 1970s, computer- aided finite element analysis en- abled ABS to class a number of innovative ship types—large self- propelled LNG carriers, pure con- tainer and barge carriers, very large crude carriers, floating industrial units, rigidly integrated tug-barge combinations, and mobile offshore drilling units.

Also, with the innovations of the 1960s, there arose a need for classifi- cation standards for application to special purpose vessels whose unique structural or mechanical fea- tures were not comprehensively cov- ered by the ABS rules for steel ves- sels. Therefore, ABS published guides covering the construction and classification of nuclear ships, underwater systems and vehicles and mobile drilling units. As the years went on, ABS special rules and guides have been published to fit the needs of the marine and off- shore industry, and in 1987, its 125th year, ABS published 21 dif- ferent guides, including the Guide for Building and Classing Offshore

Racing Yachts, and 16 different rules.

In 1970, ABS Worldwide Techni- cal Services, Inc. (ABSTECH) was formed as a wholly owned subsid- iary of ABS to provide certification, inspection, analysis and quality as- surance services to the marine sec- tor for functions above and beyond those traditionally performed and also to related nonclassification ser- vices in the industrial sector.

In 1978, ABS commenced classifi- cation and certification services with site specific structures of vari- ous types including single point moorings, hydrocarbon production and processing structures, floating production storage offloading units, and steel and concrete caisson drill- ing units and concrete islands.

As the 1970s moved on to the 1980s, ABS activity with all types of vessels continued to increase, but its work with the offshore sector grew the fastest. ABS had been involved with mobile offshore drilling units (MODUs) since their inception in the Gulf of Mexico some 25 years earlier. About two-thirds of the world's MODUs are ABS classed.

Late in 1981 and early 1982, the

U.S. Coast Guard signed a two-year

Memorandum of Understanding with ABS under the terms which the Coast Guard agreed to accept

ABS plan review and inspection of various hull and machinery items for construction of U.S.-flag vessels built to ABS class and USCG certi- fication requirements. As exten- sions of this Memorandum in early 1982 the Coast Guard also agreed to accept ABS admeasurement and tonnage certification of their be- half.

The 1980s saw the continued ex- pansion of their services. ABS ser- vices encompassed such areas as marine hydrodynamics, seakeeping, stability, mooring analysis, finite element structural mechanics and structural dynamics, vibration and noise prediction and prevention, and fatigue analysis. In another area survey methods were developed by

ABS during this time to replace tra- ditional ones. Typical of this is the comprehensive preventive mainte- nance program based on condition monitoring using such techniques as vibration analysis, lubrication oil analysis, and other more sophisti- cated techniques to determine the operational conditions of a particu- lar machinery item.

During the same period, ABS also developed synchronized surveys in order to help owners time various classification surveys and those re- quired by international marine safe- ty conventions so that they would coincide to the maximum extent possible. Other survey procedures were offered such as underwater in- spection, voyage surveys, and tail- shaft monitoring in lieu of with- drawal. During this period, ABS de- veloped its quality assurance system of programs for individual, batch, and mass produced products, as well as manufacturing processes. These services have become well accepted and by the beginning of 1986, al- most 1,000 manufacturers were en- rolled in the various ABS quality assurance and related programs.

In 1983, a new division of

ABSTECH, called ABS Boiler Ma- rine and Insurance Company, was formed to carry out examinations of boilers, pressure vessels and pres- sure-related equipment according to

ASME code. Additionally, that same year a second ABSTECH divi- sion, ABS Oil Testing Services, Inc., was formed to complete tests of bunker fuels and lubricating oils used in main onboard propulsion and machinery systems and power generation and industrial plants.

To better fit everyday use of the

ABS rules with computer technolo- gy, in 1985 ABS instituted the EA-

GLE system of computer programs.

This system is available to ship- yards, designers and other outside users as well as ABS and has great potential benefit to all by affording substantial time and cost saving by accelerating the ABS plan review process in addition to eliminating duplication of effort. By the end of 1986, EAGLE contained several of the ABS rules and the aim is to include all of the computer pro- grams for ABS rules in its vocabu- lary and also computer programs for a wide spectrum of related functions such as hull girder strength, ship hydrostatics, structural frame anal- ysis and stability.

The 125th year of ABS, cele- brated last year, saw the enactment of an important new business ap- proach. ABS intensified its activi- ties in nonmarine and nonclassifica- tion work as well as concentrated on its basic classification business. For this purpose the ABS organization was reorganized into three groups— the American Bureau of Shipping, which will continue classification and statutory work; ABS World- wide Technical Services, Inc. (ABSTECH), which will continue and intensify marine and industrial advisory services; and ABS Govern- ment Services Business Unit (GSBU), which will provide non- classification marine services to gov- ernment agencies worldwide.

For free literature containing de- tailed information on the full range

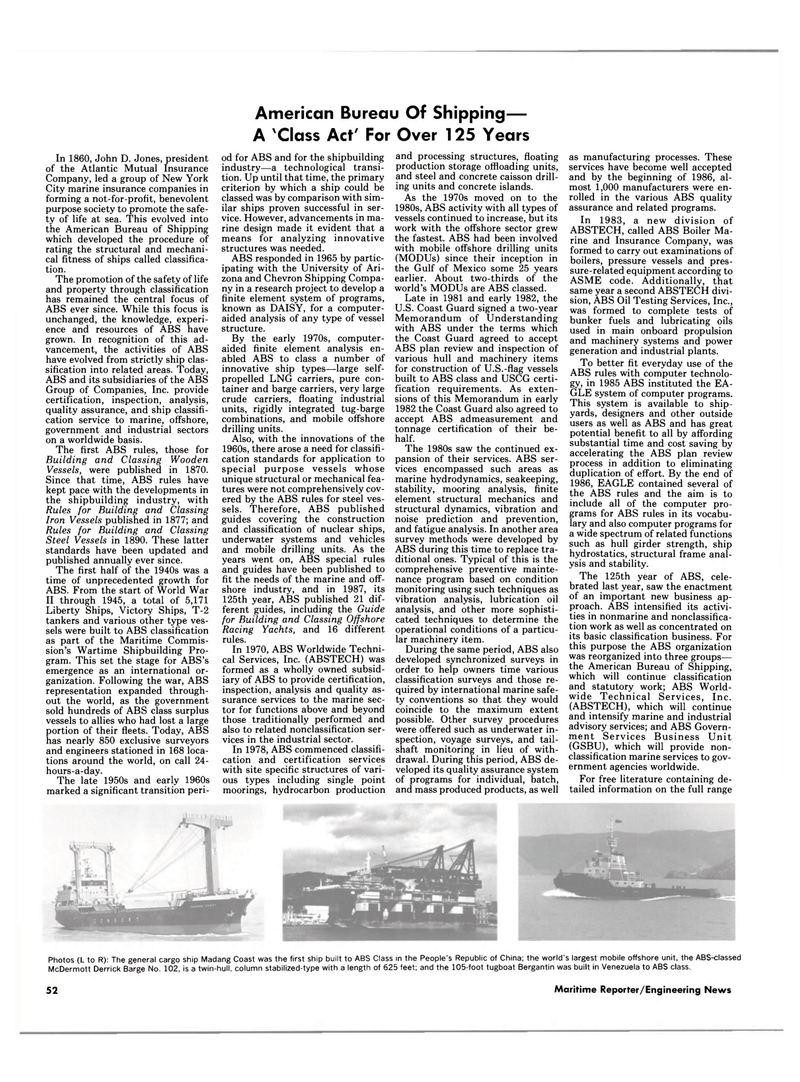

Photos (L to R): The general cargo ship Madang Coast was the first ship built to ABS Class in the People's Republic of China; the world's largest mobile offshore unit, the ABS-classed

McDermott Derrick Barge No. 102, is a twin-hull, column stabilized-type with a length of 625 feet; and the 105-foot tugboat Bergantin was built in Venezuela to ABS class. 52 Maritime Reporter/Engineering News

49

49

51

51