Page 9: of Maritime Reporter Magazine (March 1988)

Read this page in Pdf, Flash or Html5 edition of March 1988 Maritime Reporter Magazine

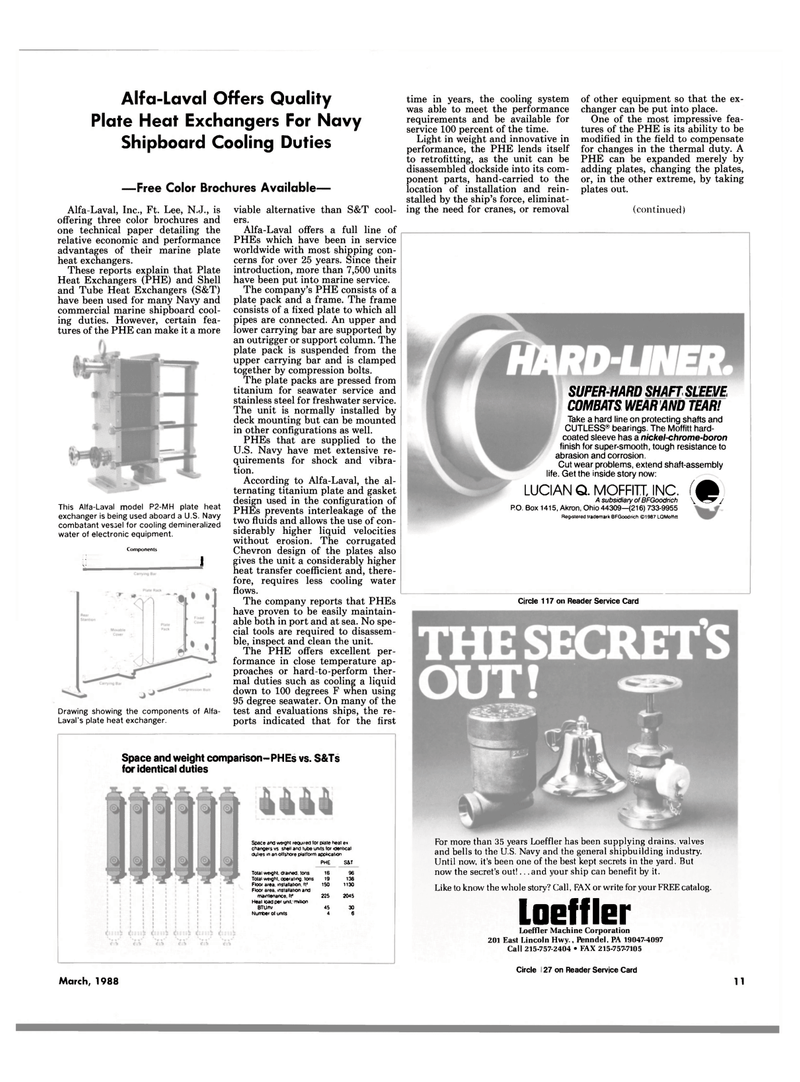

Space and weight comparison-PHEs vs. S&Ts for identical duties

Space and wetgni requited lor plate neat e« changers vs shell and tuOe units tea identical duties in an onshore piattorm application

PHE SAT

Total weight, drained, tons IS %

Total weight, operating, tons 19 136

Floor area, installation, it' 150 1130

Floor area, installation and maintenance. If 225 2045

Heal load per unit. mitlion

BTUrhr 45 30

Number pt units 4 6

For more than 35 years Loeffler has been supplying drains, valves and bells to the U.S. Navy and the general shipbuilding industry.

Until now, it's been one of the best kept secrets in the yard. But now the secret's out!... and your ship can benefit by it.

Like to know the whole story? Call, FAX or write for your FREE catalog. Loeffler

Loeffler Machine Corporation 201 East Lincoln Hwy., Penndel, PA 19047-4097

Call 215-757-2404 • FAX 215-757-7105

Alfa-Laval Offers Quality

Plate Heat Exchangers For Navy

Shipboard Cooling Duties time in years, the cooling system was able to meet the performance requirements and be available for service 100 percent of the time.

Light in weight and innovative in performance, the PHE lends itself to retrofitting, as the unit can be disassembled dockside into its com- ponent parts, hand-carried to the location of installation and rein- stalled by the ship's force, eliminat- ing the need for cranes, or removal of other equipment so that the ex- changer can be put into place.

One of the most impressive fea- tures of the PHE is its ability to be modified in the field to compensate for changes in the thermal duty. A

PHE can be expanded merely by adding plates, changing the plates, or, in the other extreme, by taking plates out. (continued) —Free Color Brochures Available—

Circle 117 on Reader Service Card viable alternative than S&T cool- ers.

Alfa-Laval offers a full line of

PHEs which have been in service worldwide with most shipping con- cerns for over 25 years. Since their introduction, more than 7,500 units have been put into marine service.

The company's PHE consists of a plate pack and a frame. The frame consists of a fixed plate to which all pipes are connected. An upper and lower carrying bar are supported by an outrigger or support column. The plate pack is suspended from the upper carrying bar and is clamped together by compression bolts.

The plate packs are pressed from titanium for seawater service and stainless steel for freshwater service.

The unit is normally installed by deck mounting but can be mounted in other configurations as well.

PHEs that are supplied to the

U.S. Navy have met extensive re- quirements for shock and vibra- tion.

According to Alfa-Laval, the al- ternating titanium plate and gasket design used in the configuration of

PHEs prevents interleakage of the two fluids and allows the use of con- siderably higher liquid velocities without erosion. The corrugated

Chevron design of the plates also gives the unit a considerably higher heat transfer coefficient and, there- fore, requires less cooling water flows.

The company reports that PHEs have proven to be easily maintain- able both in port and at sea. No spe- cial tools are required to disassem- ble, inspect and clean the unit.

The PHE offers excellent per- formance in close temperature ap- proaches or hard-to-perform ther- mal duties such as cooling a liquid down to 100 degrees F when using 95 degree seawater. On many of the test and evaluations ships, the re- ports indicated that for the first

Alfa-Laval, Inc., Ft. Lee, N.J., is offering three color brochures and one technical paper detailing the relative economic and performance advantages of their marine plate heat exchangers.

These reports explain that Plate

Heat Exchangers (PHE) and Shell and Tube Heat Exchangers (S&T) have been used for many Navy and commercial marine shipboard cool- ing duties. However, certain fea- tures of the PHE can make it a more

This Alfa-Laval model P2-MH plate heat exchanger is being used aboard a U.S. Navy combatant vessel for cooling demineralized water of electronic equipment.

Components i I

Drawing showing the components of Alfa-

Laval's plate heat exchanger.

SUPER-HARD SHAFT SLEEVE

COMBATS WEAR AND TEAR!

Take a hard line on protecting shafts and

CUTLESS® bearings. The Moffitt hard- coated sleeve has a nickel-chrome-boron finish for super-smooth, tough resistance to abrasion and corrosion.

Cut wear problems, extend shaft-assembly life. Get the inside story now:

LUCIAN Q. MOFFITT, INC. A

A subsidiary of BFGoodrich \^^^ J

P.O. Box 1415, Akron, Ohio 44309—(216) 733-9955

Registered trademark BFGoodrich ©1987 LQMotfitt

March, 1988

Circle 287 on Reader Service Card 11

8

8

10

10