Page 29: of Maritime Reporter Magazine (October 1988)

Read this page in Pdf, Flash or Html5 edition of October 1988 Maritime Reporter Magazine

final outfitting at McDermott Ship- yard before she goes in service in the

Gulf of Mexico.

A self-propelled dynamically po- sitioned monohull vessel, DB 50 is designed for worldwide operation in a variety of marine construction roles. She is 495 feet long and 151 feet wide with a depth from keel to main deck of 41 feet. Four 3,000-hp electrically driven azimuthing, con- trollable-pitch thrusters provide propulsion, mooring assistance and full dynamic positioning. Dynamic positioning is controlled by a GEC

Uni-Control Duplex DP System rated for all modes of construction work, including DP diving opera- tions. A GEC Tams 80 mooring sys- tem monitors position and anchor lines and has computer-assisted thruster control. She can reach speeds of 11 knots.

The ship's main revolving crane is a Clyde Model 80-262-49-33. Its components include a fully active computerized motion suppression and heel compensation system. The crane has a 344.5-foot boom with the main block at 262.5 feet. It is mounted on an 80-foot diameter tub at the centerline aft of the vessel. At full revolving, it has a rated capacity of 3,527 short tons at 82 feet. Her slewing capacity over the stern is 4,189 short tons at a 100-foot radius.

The Clyde crane has a fixed rating over the stern of 4,400 short tons at 121-foot radius.

Five 2,700-kw, 6,600-V, three- phase, 60-cycle alternators powered by Allen Model S37 diesel engines provide ample electrical power to the entire vessel.

The vessel's mooring system is composed of eight 26,460-pound

Delta Flipper anchors, each with 7,710 feet of 3-inch diameter 6 x 36

IWRCIPS wire rope on eight single- drum Hagglund anchor hoists. Pow- er for the hoists is provided by four 225-kw electrohydraulic units.

The firefighting capacity of the

DB 50 consists of four fire monitors located on the main crane mast.

Each monitor is capable of sending a 7,900 gpm stream of seawater to a point 500 feet away to a maximum height of 230 feet. The ability to provide such a great volume of water, coupled with the mobility supplied by the dynamic positioning system, allows the DB 50 to furnish excellent firefighting capability to the Gulf of Mexico.

For pile driving, the vessel is out-

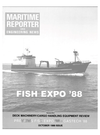

The self-propelled McDermott Derrick Barge 50, reportedly the world's largest monohull crane vessel, has a Clyde main crane with a lifting capacity of 4,400 tons. With a whip hook, the crane's maximum height is 400 feet—the approximate equivalent of a 40-story build-

World's Largest Monohull Crane Ship

To Be Outfitted At McDermott Yard

The world's largest monohull Construction's new Derrick Barge crane vessel, McDermott Marine 50, has arrived in New Orleans for

TZelia&ie

MARINE WAVEGUIDE COMPONENTS

X-LX-3cm Also: 10cm 90° E-PLANE BEND

SX-998

H-PLANE BEND m

SX-1001, LX-1001 90° H-PLANE BEND

SX-999 0 RING KIT o o

SX-1002, LX-1002

WAVEGUIDE PRESSURE GAGE

SX-1005, LX-1005

DECK FLANGE

SX-1008, LX-1008 90 E-PLANE BEND

SX-1000, LX 1000 90° TWIST

SX-1003, LX-1003

FLEXIBLE WAVEGUIDE

SX-1006, LX-1006

ROTARY JOINTS DECK GLAND ASSEMBLY WAVEGUIDE FLANGES

SX-1011

SX-LX TRANSITION 9 '» r^4

SX-1004

WAVEGUIDE STANDOFFS

SX-1007, LX-1007

SX 1013, LX-1013 SX-1015, LX-1015

ALL COMPONENTS IN STOCK

SPACE MACHINE & ENGINEERING CORP. 2346 16th AVENUE NORTH ST. PETERSBURG, FLORIDA 33713 TELE: (813) 323-2221

FAX: (813) 323-2376 TELEX: 556-289

WILDEN AIR OPERATED

DOUBLE DIAPHRAGM PUMPS offer • No Electrical Connections • Abrasion Resistant • Self priming • Submersible • Variable volume and pressure • Portable • Simple Clamp band construction • Write for free literature and prices

In

Water. one stands alone

It also stands up to chemicals, grout, resin, oil, glue and low density powders.

The heart of the Wilden air-oper- ated double diaphragm pump is its unique air valve which shifts the air supply to both dia- phragms alternately with com- plete reliability under all condi- tions of head and flow.

Up to 90% solids and over 250' heads are no problem for the

WILDEN PUMP. Our double diaphragm design cuts velocity in pump to half total discharge velocity. The most abrasive slur- ries are handled with ease since there are no seals and no metal to metal contact.

Volume is infinitely variable by controlling air flow to pump, from a few gallons per minute to over 14,000 gallons per hour. No pressure relief valve is required and the pump can run dry inde- finitely.

Wilden pumps are available with wetted parts in aluminum, cast iron, stainless steel, and Hastel- loy C. Non-wetted parts in alu- minum or cast iron. Elastomers in Neoprene, Buna N, Nordel,

Viton®, and Teflon®.

WILDEN PUMP & ENGINEERING CO. 22069 VAN BUREN ST., P.O. BOX 845, COLTON. CALIFORNIA 92324 / (714) 783-0621 / TELEX 676-452 31

Circle 275 on Reader Service Card Circle 225 on Reader Service Card Circle 159 on Reader Service Card

Maritime Reporter/Engineering News

28

28

30

30