Page 55: of Maritime Reporter Magazine (November 1988)

Read this page in Pdf, Flash or Html5 edition of November 1988 Maritime Reporter Magazine

use on Navy combatant vessels; the first stored-energy, spring-charged breakers for naval vessels; the first use of glass reinforced polyester for insulation and support material in

Navy switchgear; and a three-pole

DC circuit breaker for low magnetic signature application.

In 1988, SPD introduced the Xac- tron 102, which provides a new level of reliability for Navy combatants, and paves the way for a whole new generation of circuit breaker tech- nology.

The Xactron 102 offers a combi- nation of shock and vibration resist- ance, reduced temperature sensitiv- ity and protection selectivity. The

Xactron 102 is interchangeable with

Navy-type thermal-magnetic 100a- mp breakers now in use.

The key to the development of the Xactron 102 is the application of a simplified electronic circuit which meets the demanding size restric- tions of the 100-amp casing.

According to SPD, the integration of electronic controls also leads to a significant reduction in moving parts, which provides for increased reliability over thermal-magnetic breakers.

The development of Xactron 102 comes on the heels of another im- portant breakthrough for SPD—an advanced new computerized all-cell battery monitoring system for use oon diesel and nuclear-powered submarines and other critical bat- tery power situations.

The advanced BMS-100 system offers a combination of functional and cost efficiency never before available in MIL-SPEC battery monitoring systems for submarine use, where precise measurement of power status is critical.

Key elements in the advanced system are a unique new digital transponder probe amd proprietary computer software to provide a new standard in data acquisition, pre- dictive capability, reliability and ease of operation.

Responding to increased world- wide demand for its products, SPD has expanded its international mar- keting and technical staff and added to its role of distributors around the world.

In 1988, SPD experienced a major breakthrough in the international market when the firm was con- tracted to develop a special design version of its new all-cell battery monitoring system for Canada's De- partment of National Defense.

In addition, SPD is working close- ly with the Norwegian Navy on the application of new advances in elec- tronic circuit breaker design on their fleet.

SPD now has distributors and representatives in 15 countries around the world.

With a concentrated focus on serving the naval market and a strong capital position, SPD has mounted an aggressive acquisitions program,

The acquisition of Brown Boveri's

Naval Switchgear Division in June 1988, adds significantly to SPD's total systems capabilities, solidify- ing its position as the nation's larg- est developer and producer of elec- trical distribution and protection systems for naval ships.

Additional capacity to produce high-quality switchgear also en- hances SPD's cost efficiency and provides additional opportunities to diversify.

Furthermore, the addition of re- pair and overhaul installations in

San Diego, Calif., and Groton,

Conn., established the framework for a nationwide complex to provide on-site services at primary U.S.

Navy homeports.

Other SPD repair and overhaul installations are in Philadelphia,

Pa., and Virginia Beach, Va.

For free literature fully detailing

SPD's circuit breakers and electri- cal systems protection equipment

Circle 14 on Reader Service Card

HAL Acquires

Wind Star Sail Cruises

Holland America Line (HAL), which already had a 50 percent share in Wind Star Sail Cruises, recently took full control of the pas- senger line by purchasing the re- maining 50 percent share of the company.

With the purchase, HAL acquires full control over three 148-passen- ger sailing ships—the Wind Star,

Wind Song and Wind Spirit—which operate in the Caribbean and the

Pacific. Combined with its own fleet, HAL will now be able to offer over 5,000 passenger berths.

And because the Towmaster also re- duces rudder torque and makes more efficient use of propeller thrust, vessel operation is easier and less fatiguing.

The Michigan Wheel Towmaster Nozzle/

Rudder System. It's proven its ability to increase maneuverability and overall operating efficiency in over 100 applica- tions. To learn how it can do the same for you, contact Michigan Wheel for complete facts and the name of the distributor nearest to you.

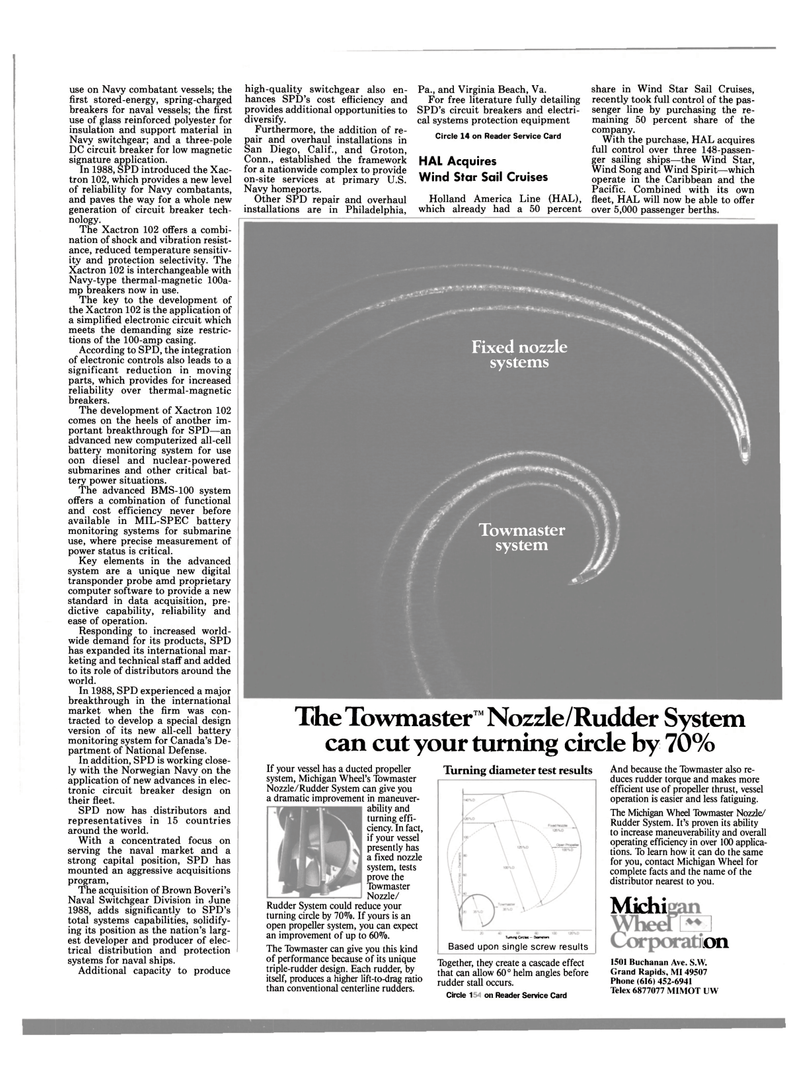

The Towmaster™ Nozzle/Rudder System can cut your turning circle by 70%

Turning diameter test results

Turning Circles — Diameters

The Towmaster can give you this kind of performance because of its unique triple-rudder design. Each rudder, by itself, produces a higher lift-to-drag ratio than conventional centerline rudders.

Based upon single screw results

Michi on

Together, they create a cascade effect that can allow 60° helm angles before rudder stall occurs. <• Circle 126 on Reader Service Card 1501 Buchanan Ave. S.W.

Grand Rapids, MI 49507

Phone (616) 452-6941

Telex 6877077 MIMOT UW

Fixed nozzle systems

Towmaster system

If your vessel has a ducted propeller system, Michigan Wheel's Towmaster

Nozzle/Rudder System can give you a dramatic improvement in maneuver- ability and turning effi- ciency. In fact, if your vessel presently has a fixed nozzle system, tests prove the

Towmaster

Nozzle/

Rudder System could reduce your turning circle by 70%. If yours is an open propeller system, you can expect an improvement of up to 60%.

54

54

56

56