Page 72: of Maritime Reporter Magazine (November 1988)

Read this page in Pdf, Flash or Html5 edition of November 1988 Maritime Reporter Magazine

Employee Buyout Helps

Seattle Yard Emerge

From Bankruptcy

In one of the largest union-led buyouts in recent years, over 400 union and non-union shipyard workers became the owners of Seat- tle-based tug and barge builder WFI

Industries, helping the company to emerge from bankruptcy. The firm will now be known as Unimar Inter- national.

Donald Liddle, former presi- dent of the Inlandboatmen's Union, became chairman and chief execu- tive officer of Unimar International.

Mr. Liddle, head of one of the 12 unions involved in the buyout, was instrumental in arranging the help of Drexel Burnham Lambert, the investment banking firm, to formu- late a buyout plan.

Under the reorganization plan,

Unimar will have two operating sub- sidiaries—United Marine Ship- building, Inc. and United Marine

Tug and Barge Inc. Richard

Woeck, former owner of WFI, will head United Marine Shipbuilding, while Michael Woeck, will run

United Marine Tug & Barge.

Employees will own 73 percent of the common stock of Unimar through an employee stock owner-

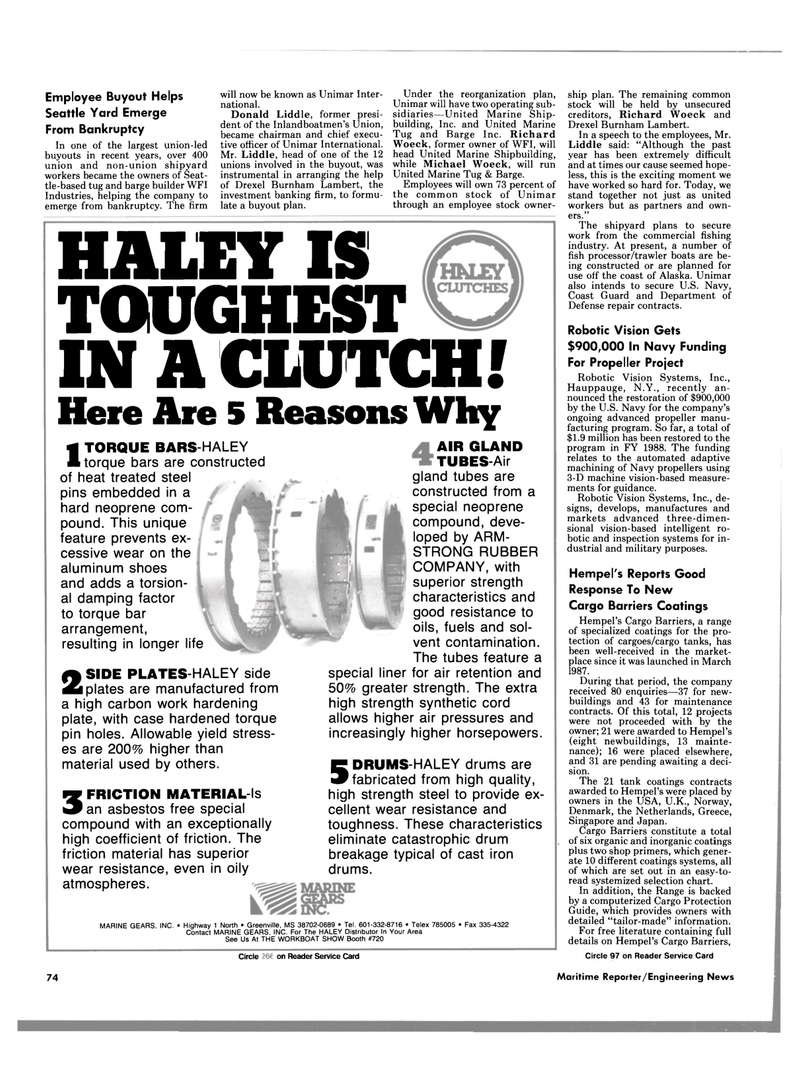

HALEY IS TOUGHEST

IN A CLUTCH!

Here Are 5 Reasons Why 1TORQUE BARS-HALEY torque bars are constructed of heat treated steel pins embedded in a hard neoprene com- pound. This unique feature prevents ex- cessive wear on the aluminum shoes and adds a torsion- al damping factor to torque bar arrangement, resulting in longer life 2SIDE PLATES-HALEY side plates are manufactured from a high carbon work hardening plate, with case hardened torque pin holes. Allowable yield stress- es are 200% higher than material used by others. 3FRICTION MATERIAL-IS an asbestos free special compound with an exceptionally high coefficient of friction. The friction material has superior wear resistance, even in oily atmospheres.

AIR GLAND

TUBES Air gland tubes are constructed from a special neoprene compound, deve- loped by ARM-

STRONG RUBBER

COMPANY, with superior strength characteristics and good resistance to oils, fuels and sol- vent contamination.

The tubes feature a special liner for air retention and 50% greater strength. The extra high strength synthetic cord allows higher air pressures and increasingly higher horsepowers. 5DRUMS-HALEY drums are fabricated from high quality, high strength steel to provide ex- cellent wear resistance and toughness. These characteristics eliminate catastrophic drum breakage typical of cast iron drums.

MARINE GEARS INC • Highway 1 North • Greenville, MS 38702-0689 • Tel. 601-332-8716 • Telex 785005 • Fax 335-4322

Contact MARINE GEARS, INC. For The HALEY Distributor In Your Area

See Us At THE WORKBOAT SHOW Booth #720

Circle 183 on Reader Service Card ship plan. The remaining common stock will be held by unsecured creditors, Richard Woeck and

Drexel Burnham Lambert.

In a speech to the employees, Mr.

Liddle said: "Although the past year has been extremely difficult and at times our cause seemed hope- less, this is the exciting moment we have worked so hard for. Today, we stand together not just as united workers but as partners and own- ers."

The shipyard plans to secure work from the commercial fishing industry. At present, a number of fish processor/trawler boats are be- ing constructed or are planned for use off the coast of Alaska. Unimar also intends to secure U.S. Navy,

Coast Guard and Department of

Defense repair contracts.

Robotic Vision Gets $900,000 In Navy Funding

For Propeller Project

Robotic Vision Systems, Inc.,

Hauppauge, N.Y., recently an- nounced the restoration of $900,000 by the U.S. Navy for the company's ongoing advanced propeller manu- facturing program. So far, a total of $1.9 million has been restored to the program in FY 1988. The funding relates to the automated adaptive machining of Navy propellers using 3-D machine vision-based measure- ments for guidance.

Robotic Vision Systems, Inc., de- signs, develops, manufactures and markets advanced three-dimen- sional vision-based intelligent ro- botic and inspection systems for in- dustrial and military purposes.

Hempel's Reports Good

Response To New

Cargo Barriers Coatings

Hempel's Cargo Barriers, a range of specialized coatings for the pro- tection of cargoes/cargo tanks, has been well-received in the market- place since it was launched in March 1987.

During that period, the company received 80 enquiries—37 for new- buildings and 43 for maintenance contracts. Of this total, 12 projects were not proceeded with by the owner; 21 were awarded to Hempel's (eight newbuildings, 13 mainte- nance); 16 were placed elsewhere, and 31 are pending awaiting a deci- sion.

The 21 tank coatings contracts awarded to Hempel's were placed by owners in the USA, U.K., Norway,

Denmark, the Netherlands, Greece,

Singapore and Japan.

Cargo Barriers constitute a total of six organic and inorganic coatings plus two shop primers, which gener- ate 10 different coatings systems, all of which are set out in an easy-to- read systemized selection chart.

In addition, the Range is backed by a computerized Cargo Protection

Guide, which provides owners with detailed "tailor-made" information.

For free literature containing full details on Hempel's Cargo Barriers,

Circle 97 on Reader Service Card 74 Maritime Reporter/Engineering News

71

71

73

73