Page 24: of Maritime Reporter Magazine (May 1989)

Read this page in Pdf, Flash or Html5 edition of May 1989 Maritime Reporter Magazine

Service Marine (continued) over mechanical engine controls, supplied by MMC of Seattle.

Service Marine also has a second vessel under construction at its

Morgan City yard for Cruise Inter- national. Called the Spirit of Mount

Vernon, this 145-foot three-deck vessel will offer tour service to the

Mount Vernon home of George

Washington. The 400-passenger vessel will dock on the Potomac Riv- er in Washington, D.C., using the same facilities as the Spirit of

Washington. This vessel is set for a

June 1989 delivery.

Cruise International has become one of the largest operators of din- ner cruise ships in the country, grossing over $25 million annually.

In 1989, nine Spirit ships, located in eight different cities will employ over 1,200 people nationally, and will entertain nearly 1.3 million pas- sengers.

For free literature fully describing the facilities and capabilities of Ser- vice Marine,

Circle 3 on Reader Service Card

Selecting Machinery (continued from page 21) er plant. But what are the most effi- cient and most flexible solutions available?

There are two general trends in machinery concepts. Both point in the same direction but achieve their goals in slightly different ways: die- sel mechanical machinery; and die- sel electric machinery.

It is generally believed that die- sel-electric propulsion is the only way to reduce vibration levels on- board a cruise ship. But the latest development in medium speed die- sel engines have also made it possi- ble to put very large main engines on resilient mountings, thereby meeting the strictest comfort re- quirements. Wartsila Diesel has de- veloped this technology for its com- plete engine range, unit sizes from 700 to 19,500 bhp. It is possible for these to be directly mounted on the engine block without the need for a separate intermediate foundation.

This is possible because of the stur- dy design of the engine block. This drastically reduces the required height in the engine room and the weight of the installation.

There are basically two different ways to install a main engine resil- iency: under-critical mounting; and over-critical mounting.

The final selection depends most- ly on the requirements. The best isolation of the main engines is achieved by the over-critical mount- ing, although this mounting is a lit- tle more complex to achieve.

However, many of the most re- cent Wartsila Diesel cruise ship ref- erences are based on over-critically mounted main engines. This is the case with the Future Seas being built by Atlantique and the latest newbuildings for Birka Cruises and

Silja Line at Wartsila Marine Indus- tries.

Since a cruise ship has an ex- tremely wide speed range, there are huge demands on the flexibility of the machinery. A trial speed of 21 knots requires more than twice the output compared with a cruising speed of 16 knots. If the machinery is optimized for the trial speed con- dition, the machinery will be far from optimal at normal cruising speed, i.e., the speed where most of the fuel is burned. To solve such a dilemma, it is advantageous to have the machinery divided into at least four main engines. In this way there are a multitude of operating modes to choose from, depending on the cruising speed. It should be noted that contrary to the practice of may ship operators, there are operation modes where there is an advantage in having two engines in operation on one shaft and one engine on the other shaft. The energy loss coming from the counter rudder is only in the order of 2 to 3 percent, which can easily be won back with optimal engine loading.

In many types of ships there might be an advantage to produce all or part of the electricity onboard with shaft generators. Due to the huge electricity demand combined with a relatively low propulsion re- quirement on cruise ships it is usually advantageous to avoid shaft

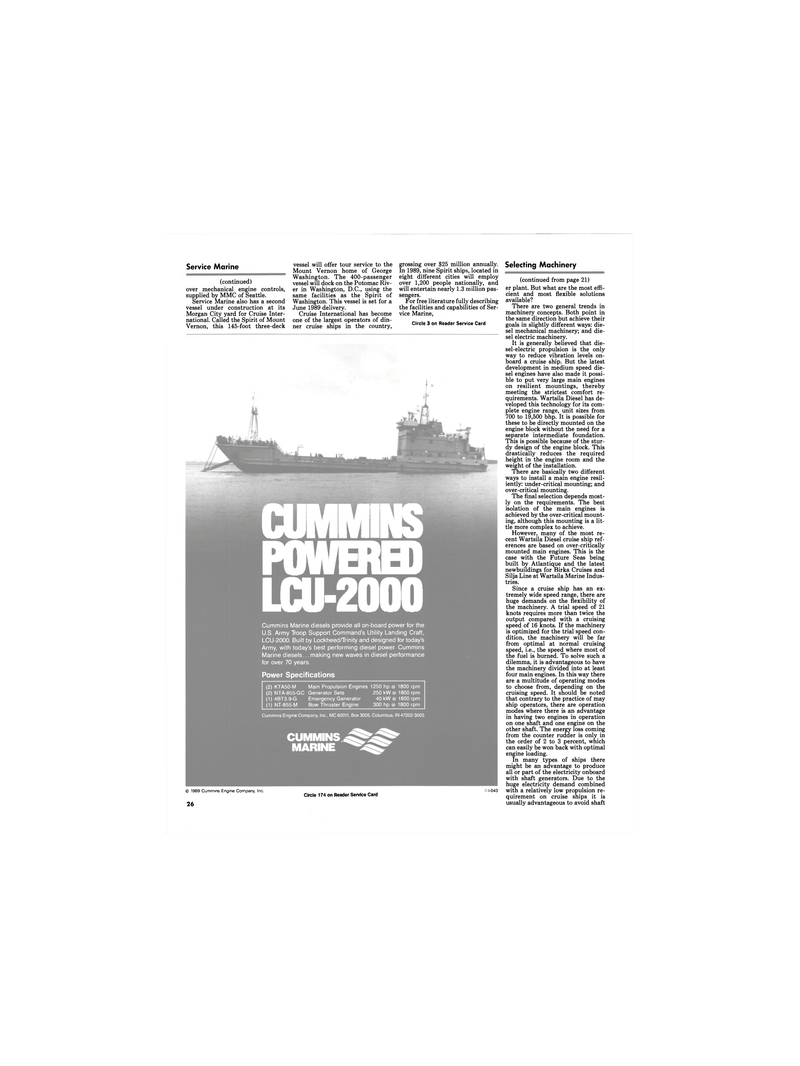

Cummins Marine diesels provide all on-board power for the

U.S. Army Troop Support Command's Utility Landing Craft,

LCU-2000. Built by Lockheed/Trinity and designed for today's

Army, with today's best performing diesel power. Cummins

Marine diesels...making new waves in diesel performance for over 70 years.

Power Specifications (2) KTA50-M Main Propulsion Engines 1250 hp @ 1800 rpm (2) NTA-855-GC Generator Sets 250 kW @ 1800 rpm (1) 4BT3.9-G Emergency Generator 40 kW @ 1800 rpm (1) NT-855-M Bow Thruster Engine 300 hp @ 1800 rpm

Cummins Engine Company, Inc., MC 60011, Box 3005, Columbus, IN 47202-3005

CUMMINS. © 1989 Cummins Engine Company, Inc. 26

Circle 174 on Reader Service Card 1-043

CUMMINS POWERED

LCU-2000

23

23

25

25