Page 48: of Maritime Reporter Magazine (June 1989)

Read this page in Pdf, Flash or Html5 edition of June 1989 Maritime Reporter Magazine

ABS/Passenger Sub Industry

SUBMARINE COMPARISON TABLE components and sections and hy- drostatic testing of the main pres- sure hull, piping systems, gas stor- age systems, and ballast tanks; per- forming detailed inspections of crit- ical hull sections in the manufactur- ing process; verifying the installa- tion and testing of mechanical and electrical systems; checking safety equipment; and verifying the imple- mentation of quality assurance pro- cedures during the fabrication of acrylic viewports.

The technical requirements used by ABS to review acrylic viewpoint designs are based on criteria in the

ANSI/ASME (American National

Standards Institute/American So- ciety of Mechanical Engineers) pub- lication "Pressure Vessels for Hu- man Occupancy." These criteria were originally developed primarily by Dr. Jerry Stachiw working with the U.S. Navy. Dr. Stachiw's work consisted of analytic studies and extensive testing to establish the suitability of using acrylics for flat and curved viewpoints on sub- mersibles.

ABS-classed submersibles em- ploy redundant ballast and trim, life-support, propulsion, and electri- cal systems to ensure the safety of passengers. ABS Rules require that submersibles carry at least a 72- hour reserve supply of oxygen and an equal carbon-dioxide-removal capability for a full complement of crew and passengers.

Propulsion systems—usually all electric—have sufficient redundan- cy to ensure safe operation. All

ABS-classed tourist submersibles are equipped with active and pas- sive firefighting systems.

Submerged tourist subs have the capability of maintaining constant contact with a support vessel via dual-frequency telephones. On the surface, subs use VHF marine-band radios.

Submersibles built to meet the stringent requirements of ABS

Rules are listed in the ABS Record as Al Manned Submersible. Na- tional administrations, lending in- stitutions, and insurers normally re- quire an Al classification or an equivalent rating before permitting a tourist submersible to operate.

During their operating life, ABS- classed submersibles undergo an- nual surveys and special surveys every three years to ensure that all significant systems are properly maintained.

In addition to its own rules, ABS works closely with—and in some cases on the behalf of—the U.S.

Coast Guard and the maritime agencies of Greece, Panama, and the

Bahamas among others. These agencies stipulate crew require- ments and oversee operating proce- dures.

New Developments

Maintaining its exemplary safety record while improving the total ex- perience for passengers are the twin goals of the tourist-sub industry.

One example of this is the continu- ing development of acrylic viewing windows—a critical technical design element of tourist subs. These plas- tic windows must maintain pressure integrity and still provide a crystal- clear view to passengers. One build- er— Hyco Technologies Corp.,

North Vancouver, B.C., Canada, is developing an entire submersible hull composed of acrylic cylinders, which would give sightseers a wra- paround view. ABS is working with

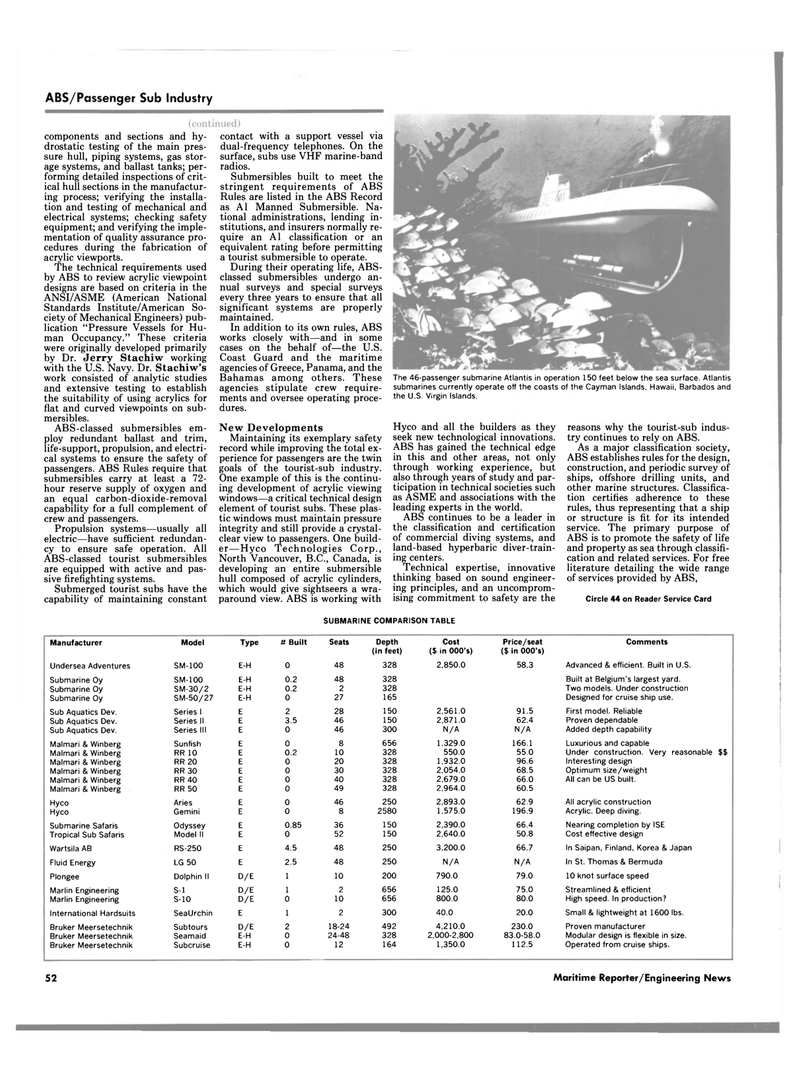

The 46-passenger submarine Atlantis in operation 150 feet below the sea surface. Atlantis submarines currently operate off the coasts of the Cayman Islands, Hawaii, Barbados and the U.S. Virgin Islands.

Hyco and all the builders as they seek new technological innovations.

ABS has gained the technical edge in this and other areas, not only through working experience, but also through years of study and par- ticipation in technical societies such as ASME and associations with the leading experts in the world.

ABS continues to be a leader in the classification and certification of commercial diving systems, and land-based hyperbaric diver-train- ing centers.

Technical expertise, innovative thinking based on sound engineer- ing principles, and an uncomprom- ising commitment to safety are the reasons why the tourist-sub indus- try continues to rely on ABS.

As a major classification society,

ABS establishes rules for the design, construction, and periodic survey of ships, offshore drilling units, and other marine structures. Classifica- tion certifies adherence to these rules, thus representing that a ship or structure is fit for its intended service. The primary purpose of

ABS is to promote the safety of life and property as sea through classifi- cation and related services. For free literature detailing the wide range of services provided by ABS,

Circle 44 on Reader Service Card

Manufacturer Model Type # Built Seats Depth Cost Price/seat Comments (in feet) ($ in 000's) ($ in 000's)

Undersea Adventures SM-100 E-H 0 48 328 2,850.0 58.3 Advanced & efficient. Built in U.S.

Submarine Oy SM-100 E-H 0.2 48 328 Built at Belgium's largest yard.

Submarine Oy SM-30/2 E-H 0.2 2 328 Two models. Under construction

Submarine Oy SM-50/27 E-H 0 27 165 Designed for cruise ship use.

Sub Aquatics Dev. Series 1 E 2 28 150 2,561.0 91.5 First model. Reliable

Sub Aquatics Dev. Series II E 3.5 46 150 2,871.0 62.4 Proven dependable

Sub Aquatics Dev. Series III E 0 46 300 N/A N/A Added depth capability

Malmari & Winberg Sunfish E 0 8 656 1,329.0 166.1 Luxurious and capable

Malmari & Winberg RR 10 E 0.2 10 328 550.0 55.0 Under construction. Very reasonable $$

Malmari & Winberg RR 20 E 0 20 328 1,932.0 96.6 Interesting design

Malmari & Winberg RR 30 E 0 30 328 2,054.0 68.5 Optimum size/weight

Malmari & Winberg RR 40 E 0 40 328 2,679.0 66.0 All can be US built.

Malmari & Winberg RR 50 E 0 49 328 2,964.0 60.5

Hyco Aries E 0 46 250 2,893.0 62.9 All acrylic construction

Hyco Gemini E 0 8 2580 1,575.0 196.9 Acrylic. Deep diving.

Submarine Safaris Odyssey E 0.85 36 150 2,390.0 66.4 Nearing completion by ISE

Tropical Sub Safaris Model II E 0 52 150 2,640.0 50.8 Cost effective design

Wartsila AB RS-250 E 4.5 48 250 3,200.0 66.7 In Saipan, Finland, Korea & Japan

Fluid Energy LG 50 E 2.5 48 250 N/A N/A In St. Thomas & Bermuda

Plongee Dolphin II D/E 1 10 200 790.0 79.0 10 knot surface speed

Marlin Engineering S-l D/E 1 2 656 125.0 75.0 Streamlined & efficient

Marlin Engineering S-10 D/E 0 10 656 800.0 80.0 High speed. In production?

International Hardsuits SeaUrchin E 1 2 300 40.0 20.0 Small & lightweight at 1600 lbs.

Bruker Meersetechnik Subtours D/E 2 18-24 492 4,210.0 230.0 Proven manufacturer

Bruker Meersetechnik Seamaid E-H 0 24-48 328 2,000-2,800 83.0-58.0 Modular design is flexible in size.

Bruker Meersetechnik Subcruise E-H 0 12 164 1,350.0 112.5 Operated from cruise ships. 52 Maritime Reporter/Engineering News

47

47

49

49