Page 35: of Maritime Reporter Magazine (July 1989)

Read this page in Pdf, Flash or Html5 edition of July 1989 Maritime Reporter Magazine

CHEVRON

Circle 40 on Reader Service Card

Chevron has recently introduced

Chevron DELO Marine Oil 477 for the inland marine trade class. It is marketed as Chevron DELO 6170

Oil for customers on the western and eastern seaboard.

Chevron's DELO Marine Oil 477 (DELO 6170 Oil) is test proven, demonstrating superior results in the field for today's new generation high-performance diesel engines.

This product is designed especially for use in engines for towboat ser- vice where some current lubricants may have limited performance and is compounded to a high alkalinity level, measuring 17 TBN (Total

Base Number) by ASTM Method

D-2896.

New engine designs require im- proved oxidation and viscosity con- trol for operating demands of fuel efficient engines with higher com- bustion pressures and tempera- tures. Increased alkalinity reserve is required for corrosive wear protec- tion and especially for operations requiring extended drain intervals.

DELO Marine Oil 477 (DELO 6170 Oil) was field tested in marine and locomotive service in GE and

EMD engines with full approval from these engine manufacturers.

Field testing demonstrated in- creased oxidation and viscosity con- trol compared to typical Generation 4 lubricants. This increased oil con- trol can allow increased drain inter- vals for GE engines and due to increased drain intervals, the added alkalinity reserve also provides the ability to extend drain intervals.

This superior oxidation stability and viscosity control was also demonstrated in EMD engines modified to run at higher operating temperatures to increase efficiency.

Chevron DELO Marine Oil 477 (DELO 6179 Oil) provides an op- timized engine oil formulation for today's service requirements for in- dustrial engine design in marine towboat and ferry service.

EXXON

Circle 103 on Reader Service Card

Diesel lubricants will continue the tradition of meeting the chal- lenge of future high performance diesel engines. However their mis- use, disregard of standard precau- tions and the pursuit of expedient solutions to operational or design problems, all invariably result in costly inefficiencies. This is the theme of a paper presented at the 18th CIMAC Congress in Tianjin,

PRC this June.

Higher wear occurs within cylin- ders because of poor combustion that can severely over-heat metal surfaces and produce excessive de- posits. Superior quality lubricants are of little use in such circum- stances and can not make up for inadequate fuel injection when this results in impingement of unburnt fuel on cylinder liners, which washes away the oil film.

Adequate oil supply to the sliding surfaces must be ensured at all times. Monetary savings achieves through reduction of oil consump- tion are illusory when, longer term, they result in reduced cylinder liner life and increased maintenance costs. Over-lubrication should also be avoided because of its economic and technical drawbacks. In es- sence, the lubricant supply should be dictated by what the engine real- ly needs for proper operation.

Over-cooling, either through in- correct design or operation, should be avoided since it causes excessive corrosive wear. Higher alkalinity lu- bricants are generally able to con- trol higher corrosive wear but are an expedient rather than an efficient solution. Adjustments and modifi- cations to engine design and opera- tion can reduce wear rates to the same low levels afforded by consid- erably higher alkalinity, hence high- er cost lubricants.

Good care of lubricants is also a source of savings. For instance, if continuous water-washing of the lu- bricant through a faulty solenoid valve in the centrifuging system goes undetected, the alkalinity of the lubricant would be affected. The control of wear and cleanliness of the engine would be impaired and an expensive renewal of the oil change may be needed.

In conclusion, incorrect use of lu- bricants is ineffient and essentially a disservice to the shipping indus- try.

Reprints of the Exxon paper "Marine Diesel Lubricants: Uses and Abuses," are available on re- quest from Exxon Company Inter- national, 200 Park Avenue, Florham

Park, NJ 07928.

MOBIL

Circle 104 on Reader Service Card

Mobil Oil Corporation announced in 1989 the introduction of a new marine diesel engine lubricant prod- uct line—Mobilmar. Mobilmar die- sel engine oils are formulated specif- ically for diesel engines used in ma- rine applications. These new oils provide superior wear protection, excellent soot and high temperature deposit control, excellent alkalinity retention, and storage stability.

Added features to these new Mobil marine lubricants are: excellent water separation characteristics and corrosion protection. Mobilmar 100

Series Oils have been designed to give optimum performance in Ma- rine applications of Detroit Diesel engines, while providing good diesel performance in fleets with mixed engines; including Caterpillar en- gines. Mobilmar 300 Series Oils have been designed to give optimum performance in Caterpillar marine applications and meet the quality characteristics needed for the Cat- erpillar 3600 Series and 3500 Series engines.

In keeping with this approach to marine diesel engine lubrication,

Mobil has also enhanced Mobilgard 450 oil to assure optimum non-zinc performance in EMD engines. Mo- bilgard 450 provides optimum per- formance for EMD engines, as well as all auxiliary and main marine engines requiring a CD-type diesel engine oil.

The Mobilgard series of marine engine oils includes Mobilgard 570, a quality marine diesel engine cylin- der oil formulated to provide out- standing performance in high-out- put crosshead engines with brake mean effective pressures (BMEP) of 14 to 17 bar. These highly loaded crosshead diesels operate on heavy fuel oil With high sulfur content in order to reduce operating costs.

Concurrently, advances in engine thermodynamics have permitted decreases in specific fuel consump- (continued)

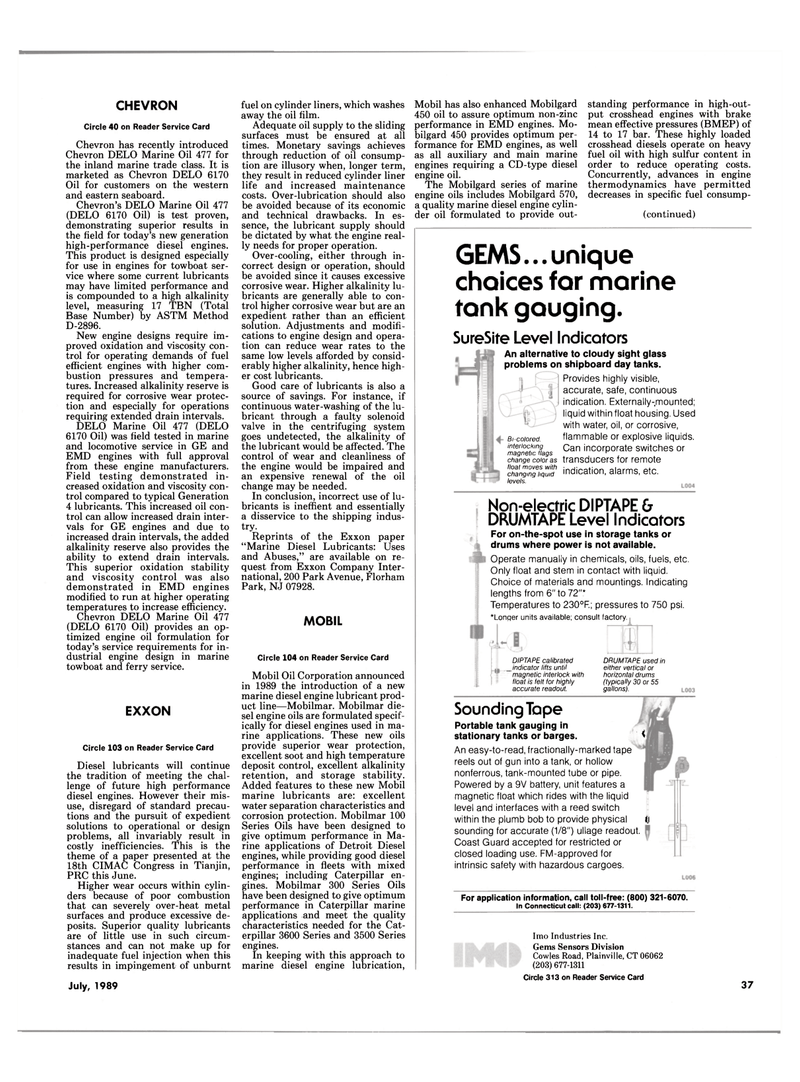

GEMS... unique choices for marine tonk gouging.

SureSite Level Indicators

Non-electric DIPTAPE b DRUMTAPE Level Indicators

For on-the-spot use in storage tanks or drums where power is not available.

Operate manually in chemicals, oils, fuels, etc.

Only float and stem in contact with liquid.

Choice of materials and mountings. Indicating lengths from 6" to 72"*

Temperatures to 230°F.; pressures to 750 psi. 'Longer units available; consult factory.

DIPTAPE calibrated _indicator lilts until magnetic interlock with float is felt for highly accurate readout.

L

DRUMTAPE used in either vertical or horizontal drums (typically 30 or 55 gallons).

Sounding Tape

July, 1989

Portable tank gauging in stationary tanks or barges. <

An easy-to-read, fractionally-marked tape reels out of gun into a tank, or hollow nonferrous, tank-mounted tube or pipe.

Powered by a 9V battery, unit features a magnetic float which rides with the liquid level and interfaces with a reed switch within the plumb bob to provide physical fl sounding for accurate (1/8") ullage readout.

Coast Guard accepted for restricted or closed loading use. FM-approved for intrinsic safety with hazardous cargoes.

For application information, call toll-free: (800) 321-6070.

In Connecticut call: (203) 677-1311.

Imo Industries Inc.

Gems Sensors Division

Cowles Road, Plainville, CT 06062 (203) 677-1311

Circle 313 on Reader Service Card 37

An alternative to cloudy sight glass problems on shipboard day tanks.

Bi-colored. interlocking magnetic flags change color as float moves with changing liquid levels.

Provides highly visible, accurate, safe, continuous indication. Externally-,mounted; liquid within float housing. Used with water, oil, or corrosive, flammable or explosive liquids.

Can incorporate switches or transducers for remote indication, alarms, etc.

34

34

36

36