Page 9: of Maritime Reporter Magazine (October 1989)

Read this page in Pdf, Flash or Html5 edition of October 1989 Maritime Reporter Magazine

face with MMS's SPIM and PMS systems being installed at Del

Monte's operation office in Hamil- ton, as well as at an additional shore office expanded to support a ware- house system. Working together, these systems will provide full in- ventory and maintenance manage- ment control for the Del Monte fleet of vessels.

AESA is also constructing five 580,000-cubic-foot reefers for Del

Monte. These vessels will each have an overall length of 520 feet, breadth of 77 feet, and draft of 30 feet. Like the smaller reefers, these five vessels will each be powered by a single AESA-built MAN B&W

Diesel 6L60MC engine.

For free color literature detailing the shipbuilding and ship-repairing services of the shipyards of AESA,

Circle 12 on Reader Service Card

MARKISCHES WERK HALVER

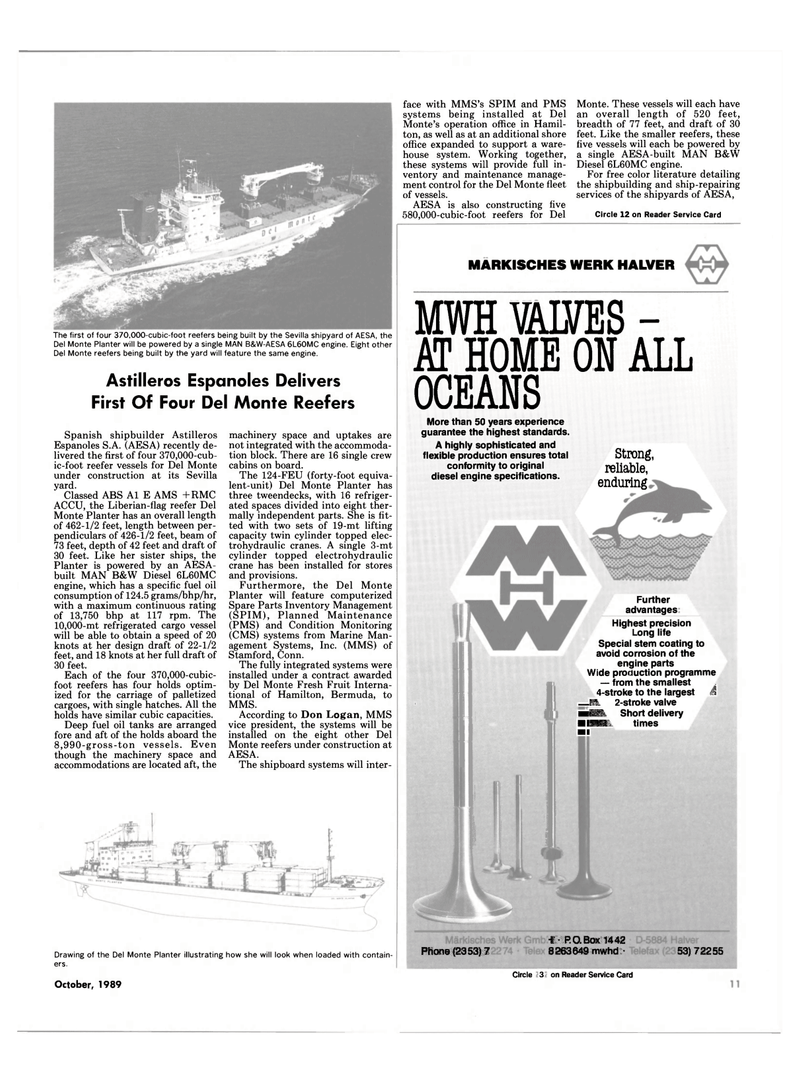

The first of four 370,000-cubic-foot reefers being built by the Sevilla shipyard of AESA, the

Del Monte Planter will be powered by a single MAN B&W-AESA 6L60MC engine. Eight other

Del Monte reefers being built by the yard will feature the same engine.

Astilleros Espanoles Delivers

First Of Four Del Monte Reefers

Spanish shipbuilder Astilleros

Espanoles S.A. (AESA) recently de- livered the first of four 370,000-cub- ic-foot reefer vessels for Del Monte under construction at its Sevilla yard.

Classed ABS A1 E AMS +RMC

ACCU, the Liberian-flag reefer Del

Monte Planter has an overall length of 462-1/2 feet, length between per- pendiculars of 426-1/2 feet, beam of 73 feet, depth of 42 feet and draft of 30 feet. Like her sister ships, the

Planter is powered by an AESA- built MAN B&W Diesel 6L60MC engine, which has a specific fuel oil consumption of 124.5 grams/bhp/hr, with a maximum continuous rating of 13,750 bhp at 117 rpm. The 10,000-mt refrigerated cargo vessel will be able to obtain a speed of 20 knots at her design draft of 22-1/2 feet, and 18 knots at her full draft of 30 feet.

Each of the four 370,000-cubic- foot reefers has four holds optim- ized for the carriage of palletized cargoes, with single hatches. All the holds have similar cubic capacities.

Deep fuel oil tanks are arranged fore and aft of the holds aboard the 8,990-gross-ton vessels. Even though the machinery space and accommodations are located aft, the machinery space and uptakes are not integrated with the accommoda- tion block. There are 16 single crew cabins on board.

The 124-FEU (forty-foot equiva- lent-unit) Del Monte Planter has three tweendecks, with 16 refriger- ated spaces divided into eight ther- mally independent parts. She is fit- ted with two sets of 19-mt lifting capacity twin cylinder topped elec- trohydraulic cranes. A single 3-mt cylinder topped electrohydraulic crane has been installed for stores and provisions.

Furthermore, the Del Monte

Planter will feature computerized

Spare Parts Inventory Management (SPIM), Planned Maintenance (PMS) and Condition Monitoring (CMS) systems from Marine Man- agement Systems, Inc. (MMS) of

Stamford, Conn.

The fully integrated systems were installed under a contract awarded by Del Monte Fresh Fruit Interna- tional of Hamilton, Bermuda, to

MMS.

According to Don Logan, MMS vice president, the systems will be installed on the eight other Del

Monte reefers under construction at

AESA.

The shipboard systems will inter-

Drawing of the Del Monte Planter illustrating how she will look when loaded with contain- ers.

October, 1989 11

Further advantages

Highest precision

Long life

Special stem coating to avoid corrosion of the engine parts

Wide production programme — from the smallest , 4-stroke to the largest J _ 2-stroke valve •r Short delivery •I times • I : -i • P.O.Box 1442 8263649 mwhd • Phone (2353) 7 53) 72255

Circle 163 on Reader Service Card

MWHmiVES-AT HOME ON ALL

OCEANS

More than 50 years experience guarantee the highest standards.

A highly sophisticated and flexible production ensures total conformity to original diesel engine specifications.

Strong, reliable, enduring

8

8

10

10