Page 41: of Maritime Reporter Magazine (January 1991)

Read this page in Pdf, Flash or Html5 edition of January 1991 Maritime Reporter Magazine

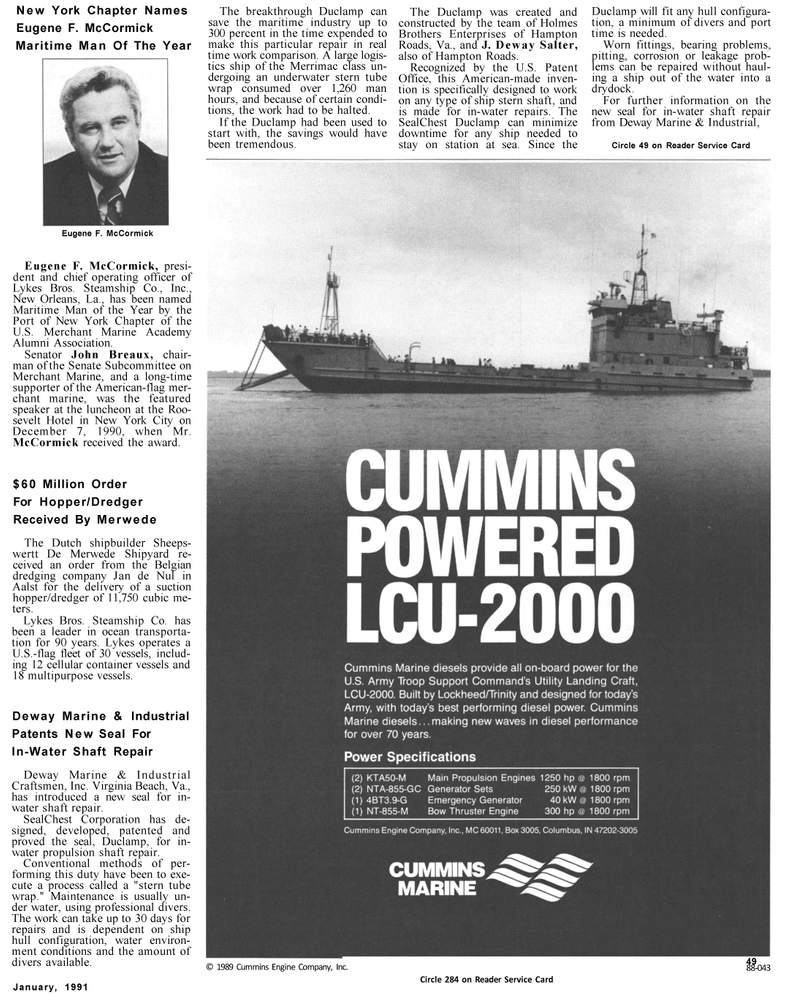

New York Chapter Names

Eugene F. McCormick

Maritime Man Of The Year

Eugene F. McCormick

Eugene F. McCormick, presi- dent and chief operating officer of

Lykes Bros. Steamship Co., Inc.,

New Orleans, La., has been named

Maritime Man of the Year by the

Port of New York Chapter of the

U.S. Merchant Marine Academy

Alumni Association.

Senator John Breaux, chair- man of the Senate Subcommittee on

Merchant Marine, and a long-time supporter of the American-flag mer- chant marine, was the featured speaker at the luncheon at the Roo- sevelt Hotel in New York City on

December 7, 1990, when Mr.

McCormick received the award. $60 Million Order

For Hopper/Dredger

Received By Merwede

The Dutch shipbuilder Sheeps- wertt De Merwede Shipyard re- ceived an order from the Belgian dredging company Jan de Nul in

Aalst for the delivery of a suction hopper/dredger of 11,750 cubic me- ters.

Lykes Bros. Steamship Co. has been a leader in ocean transporta- tion for 90 years. Lykes operates a

U.S.-flag fleet of 30 vessels, includ- ing 12 cellular container vessels and 18 multipurpose vessels.

Deway Marine & Industrial

Patents New Seal For

In-Water Shaft Repair

Deway Marine & Industrial

Craftsmen, Inc. Virginia Beach, Va., has introduced a new seal for in- water shaft repair.

SealChest Corporation has de- signed, developed, patented and proved the seal, Duclamp, for in- water propulsion shaft repair.

Conventional methods of per- forming this duty have been to exe- cute a process called a "stern tube wrap." Maintenance is usually un- der water, using professional divers.

The work can take up to 30 days for repairs and is dependent on ship hull configuration, water environ- ment conditions and the amount of divers available.

January, 1991

The breakthrough Duclamp can save the maritime industry up to 300 percent in the time expended to make this particular repair in real time work comparison. A large logis- tics ship of the Merrimac class un- dergoing an underwater stern tube wrap consumed over 1,260 man hours, and because of certain condi- tions, the work had to be halted.

If the Duclamp had been used to start with, the savings would have been tremendous.

The Duclamp was created and constructed by the team of Holmes

Brothers Enterprises of Hampton

Roads, Va., and J. Deway Salter, also of Hampton Roads.

Recognized by the U.S. Patent

Office, this American-made inven- tion is specifically designed to work on any type of ship stern shaft, and is made for in-water repairs. The

SealChest Duclamp can minimize downtime for any ship needed to stay on station at sea. Since the

Duclamp will fit any hull configura- tion, a minimum of divers and port time is needed.

Worn fittings, bearing problems, pitting, corrosion or leakage prob- lems can be repaired without haul- ing a ship out of the water into a drydock.

For further information on the new seal for in-water shaft repair from Deway Marine & Industrial,

Circle 49 on Reader Service Card © 1989 Cummins Engine Company, Inc.

Circle 284 on Reader Service Card 88-043 49

40

40

42

42