Page 28: of Maritime Reporter Magazine (January 1992)

Read this page in Pdf, Flash or Html5 edition of January 1992 Maritime Reporter Magazine

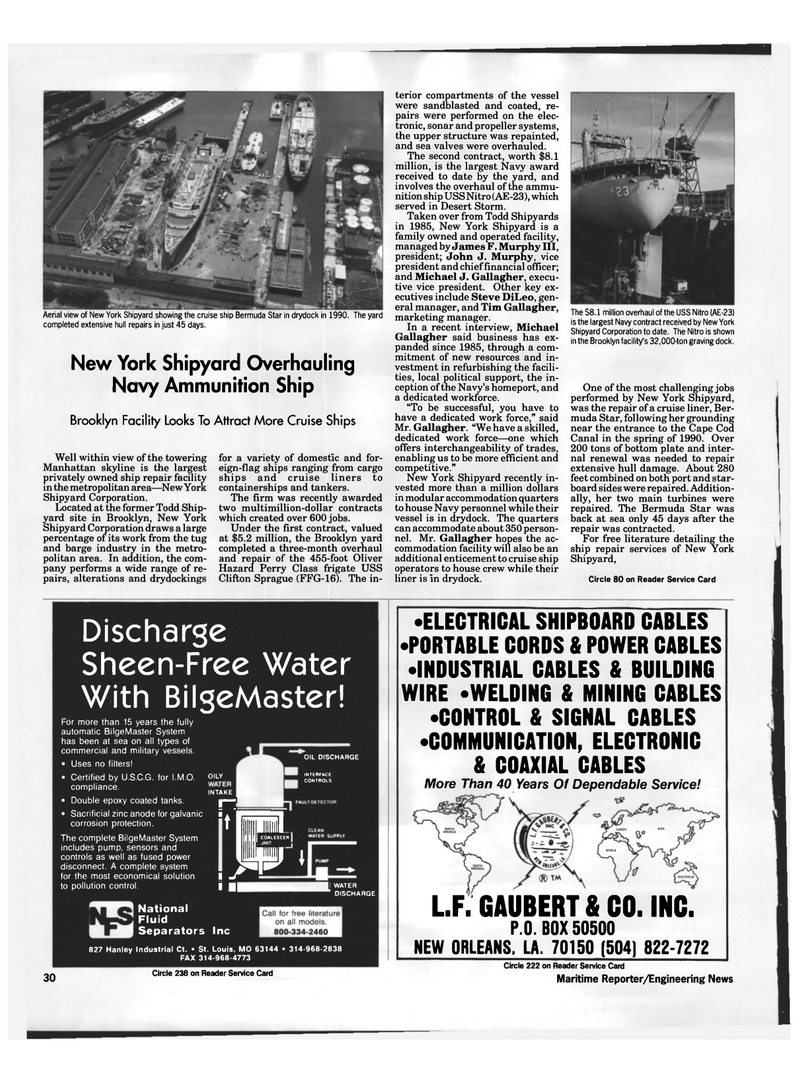

Aerial view of New York Shipyard showing the cruise ship Bermuda Star in drydock in 1990. The yard completed extensive hull repairs in just 45 days.

New York Shipyard Overhauling

Navy Ammunition Ship

Brooklyn Facility Looks To Attract More Cruise Ships

Well within view of the towering

Manhattan skyline is the largest privately owned ship repair facility in the metropolitan area—New York

Shipyard Corporation.

Located at the former Todd Ship- yard site in Brooklyn, New York

Shipyard Corporation draws a large percentage of its work from the tug and barge industry in the metro- politan area. In addition, the com- pany performs a wide range of re- pairs, alterations and dry dockings for a variety of domestic and for- eign-flag ships ranging from cargo ships and cruise liners to containerships and tankers.

The firm was recently awarded two multimillion-dollar contracts which created over 600 jobs.

Under the first contract, valued at $5.2 million, the Brooklyn yard completed a three-month overhaul and repair of the 455-foot Oliver

Hazard Perry Class frigate USS

Clifton Sprague (FFG-16). The in- terior compartments of the vessel were sandblasted and coated, re- pairs were performed on the elec- tronic, sonar and propeller systems, the upper structure was repainted, and sea valves were overhauled.

The second contract, worth $8.1 million, is the largest Navy award received to date by the yard, and involves the overhaul of the ammu- nition ship USS Nitro (AE-23), which served in Desert Storm.

Taken over from Todd Shipyards in 1985, New York Shipyard is a family owned and operated facility, managed by James F. Murphy III, president; John J. Murphy, vice president and chief financial officer; and Michael J. Gallagher, execu- tive vice president. Other key ex- ecutives include Steve DiLeo, gen- eral manager, and Tim Gallagher, marketing manager.

In a recent interview, Michael

Gallagher said business has ex- panded since 1985, through a com- mitment of new resources and in- vestment in refurbishing the facili- ties, local political support, the in- ception of the Navy's homeport, and a dedicated workforce. "To be successful, you have to have a dedicated work force," said

Mr. Gallagher. "We have a skilled, dedicated work force—one which offers interchangeability of trades, enabling us to be more efficient and competitive."

New York Shipyard recently in- vested more than a million dollars in modular accommodation quarters to house Navy personnel while their vessel is in drydock. The quarters can accommodate about 350 person- nel. Mr. Gallagher hopes the ac- commodation facility will also be an additional enticement to cruise ship operators to house crew while their liner is in drydock.

The $8.1 million overhaul of the USS Nitro (AE-23) is the largest Navy contract received by New York

Shipyard Corporation to date. The Nitro is shown in the Brooklyn facility's 32,000-ton graving dock.

One of the most challenging jobs performed by New York Shipyard, was the repair of a cruise liner, Ber- muda Star, following her grounding near the entrance to the Cape Cod

Canal in the spring of 1990. Over 200 tons of bottom plate and inter- nal renewal was needed to repair extensive hull damage. About 280 feet combined on both port and star- board sides were repaired. Addition- ally, her two main turbines were repaired. The Bermuda Star was back at sea only 45 days after the repair was contracted.

For free literature detailing the ship repair services of New York

Shipyard,

Circle 80 on Reader Service Card

Discharge Sheen-Free Water

With BilgeMaster!

For more than 15 years the fully automatic BilgeMaster System has been at sea on all types of commercial and military vessels. • Uses no filters! • Certified by U.S.C.G. for I.M.O. OILY compliance. INTAKE • Double epoxy coated tanks. p—• • Sacrificial zinc anode for galvanic * " corrosion protection.

The complete BilgeMaster System includes pump, sensors and controls as well as fused power disconnect. A complete system for the most economical solution J to pollution control. J|

OIL DISCHARGE

INTERFACE

CONTROLS •IPl.

IIMI co*lescer | Bp*

I WATER

DISCHARGE 30

National

Fluid

Separators Inc 827 Hanley Industrial Ct. • St. Louis, MO 63144 • 314-968-2838

FAX 314-968-4773

Circle 238 on Reader Service Card •ELECTRICAL SHIPBOARD CABLES •PORTABLE CORDS & POWER CABLES •INDUSTRIAL CABLES & BUILDING

WIRE *WELDING & MINING CABLES •CONTROL & SIGNAL CABLES •COMMUNICATION, ELECTRONIC & COAXIAL CABLES

More Than 40 Years Of Dependable Service!

L.F. GAUBERT & CO. INC.

P.O. BOX 50500

NEW ORLEANS, LA. 70150 (504) 822-7272

Circle 222 on Reader Service Card

Maritime Reporter/Engineering News

27

27

29

29