Page 5: of Maritime Reporter Magazine (February 1992)

Read this page in Pdf, Flash or Html5 edition of February 1992 Maritime Reporter Magazine

Circle Seal Offers Brochure

On Line Of Pressure And

Back Pressure Regulators

Circle Seal Controls, Inc. of Ana- heim, Calif., is offering an eight- page condensed brochure that pro- vides technical data and specifica- tions on Circle Seal Controls' stan- dard line of pressure and back pres- sure regulators.

Circle Seal regulators are avail- able with outlet ranges up to 10,000 psi in 1/4-inch to 1/2-inch pipe sizes.

The regulators come in a variety of configurations to meet different ap- plication requirements.

Circle Seal Controls maintains a staff of highly qualified engineers, designers, and technicians plus out- standing production, assembly and testing facilities. Quality Control standards that meet or exceed the rigid requirements dictated by com- mercial industrial and marine cus- tomers have always been the prime consideration of Circle Seal Con- trols.

For further information regard- ing special regulator configurations,

Circle 82 on Reader Service Card

KHI To Invest $15.5 Million Yearly

To Automate Yard

Japanese shipbuilder Kawasaki

Heavy Industries (KHI) is expected to invest $15.5 million annually over the next four fiscal years in its

Sakaide Works, developing it into one of the most highly automated shipyards in the world.

Beginning in fiscal year 1992, which runs from April 1992 to

March 1993, and running through fiscal year 1995, KHI will introduce automatic steel cutting and process lines of section steels at the yard.

Additionally, the number of seven- shaft multi-joint welding robots for assembling of blocks for hulls will be doubled to 12. The additional robots will not only shorten work- ing time, but also reduce the num- ber of workers needed, creating an automatic cutting line by combin- ing robots with belt conveyors.

Another improvement at the shipyard, which is engaged in the construction of VLCCs and LNG carriers, will include the addition of a steel conveyor and automatic arc welding machine at the indoor plant for handling the manufacture of components for the main assem- bling work after processing steel materials and subassemblingthem.

French Company Receives

Orders For New

Quadrimaran

A French team of engineers headed by Daniel Toilet of FC4

International has received orders for two 26-meter Quadrimarans, a new generation high-speed, plan- ing surface effect vessel design.

FC4's first commercial customer is a consortium of French banks,

February, 1992 7 lead by Credit Agricole, which or- dered two 26-meter Quadrimarans, for use in Martinique for delivery in

June 1992.

A 190-foot vessel capable of speeds in excess of 70 knots is currently under construction at the company's yard outside Marseilles in France.

After a year of promotional activities visiting Europe, the U.S. and Asia, the 1992 Summer Olympics in

Barcelona and the World's Fair in

Seville, the vessel will be launched in June 1992 and used as a 700- passenger ferry.

FC4's main development partners are Sollac S.A., the world's second largest steel producer, and Societe

General, a major French bank.

The company also recently an- nounced that it had entered into an agreement with a shipping syndi- cate for a 122-meter container ves- sel.

The Jonathan Corporation, a Nor- folk-based engineering company which owns shipyards, is assisting

FC4 International S.A. in establish- ing the Quadrimaran concept on the

U.S. market.

The Baltimore Steam Packet

Company, Williamsburg, Va., is mar- keting the vessel in the U.S.

For free literature detailing the new Quadrimaran design,

Circle 23 on Reader Service Card

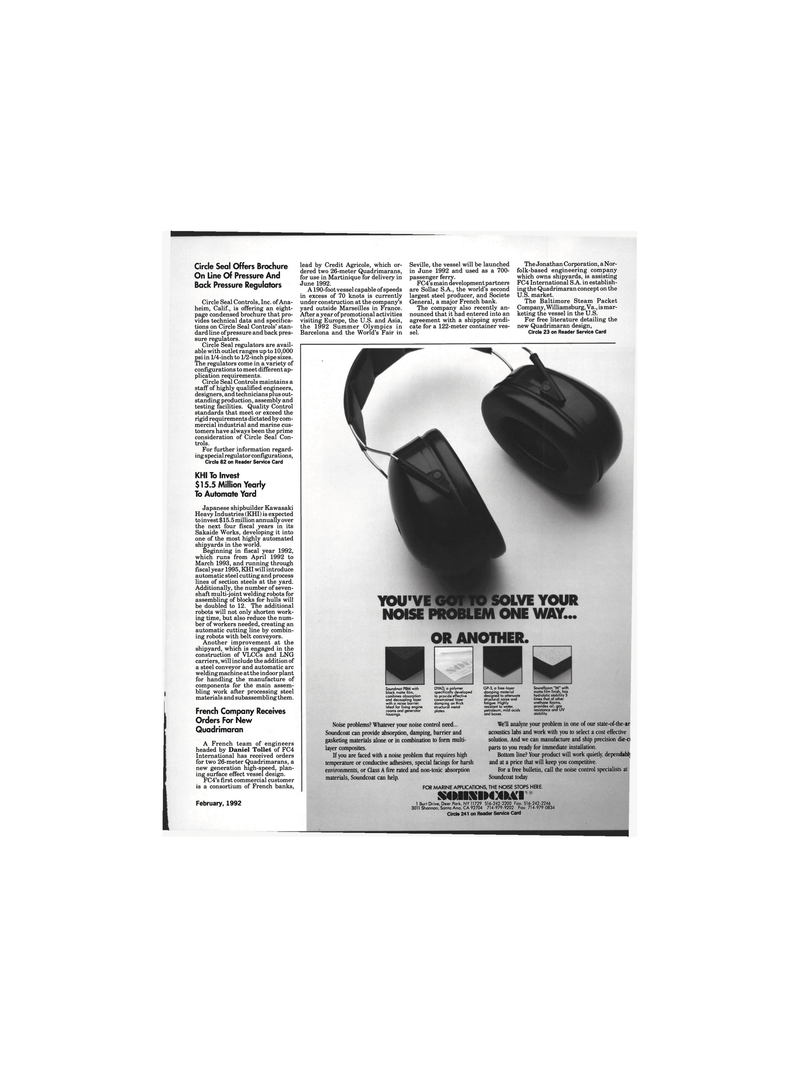

Soundmat PBM with black matte film, combines absorption and decoupling layer with a noise barrier.

Ideal for lining engine rooms and generator housings.

DYAD, a polymer specifically developed to provide effective constrained layer damping on thick structural metal plates.

GP-3, a free-layer damping material designed to attenuate structural noise and fatigue. Highly resistant to water, petroleum, mild acids and bases.

Soundfoam "M" with matte film finish, has hydrolvtic stability 5 times that of other urethane foams, provides oil, gas resistance and UV stability.

Noise problems? Whatever your noise control need...

Soundcoat can provide absorption, damping, barrier and gasketing materials alone or in combination to form multi- layer composites.

If you are faced with a noise problem that requires high temperature or conductive adhesives, special facings for harsh environments, or Class A fire rated and non-toxic absorption materials, Soundcoat can help.

We'll analyze your problem in one of our state-of-the-ar acoustics labs and work with you to select a cost effective solution. And we can manufacture and ship precision die-ci parts to you ready for immediate installation.

Bottom line? Your product will work quietly, dependably and at a price that will keep you competitive.

For a free bulletin, call the noise control specialists at

Soundcoat today.

FOR MARINE APPLICATIONS, THE NOISE STOPS HERE.

KOIISIICOA'I 1 Burt Drive, Deer Park, NY 11729 516-242-2200 Fax:516-242-2246 3011 Shannon, Santa Ana, CA 92704 714-979-9202 Fax: 714-979-0834

Circle 241 on Reader Service Card

4

4

6

6