Page 12: of Maritime Reporter Magazine (June 1992)

Read this page in Pdf, Flash or Html5 edition of June 1992 Maritime Reporter Magazine

Propulsion Update

New Electric Propulsion Drive

Developed By ABB Stromberg,

Kvaerner Masa-Yards

Marketed For Offshore, Passenger, Icebreaking Vessels

Exceptional maneuverability, low noise and vibration levels, and flexible machinery layout are among the advantages reported to be offered by a new high-power azimuthing electric propulsion drive recently introduced in Fin- land.

Jointly developed by Kvaerner

Masa-Yards (KMY), Finland's larg- est shipbuilder, and ABB Stromberg

Drives (ABB), the world's leading supplier of electric AC propulsion and power plants for ships, the new propulsion system is called the

Azipod.

Unveiled at an international press conference at the KMY Arctic

Research Center (MARC) at

Toukola, just outside of Helsinki, the Azipod is an electric propulsion system self-contained within a pod, incorporating an air-cooled electric motor which directly drives a fixed- pitch propeller. The AC synchro- nous motor located inside the pod is controlled by a cycloconverter, with full torque available in either direc- tion over a speed range of 0 to 200 rpm.

Inherent in the system's design is the elimination of a long tailshaft, since the shaft is actually located within the pod. This increases the space available in the vessel for cargo or passengers, while offering the ship designer more flexibility in arrang- ing the engines. Additionally, the use of rudders, transverse stern thrusters, CP propellers and reduc- tion gears are not required with the

Azipod system.

Rotating through a full 360 de- grees, the Azipod, which will be avail- able in power ranges up to 20 MW, is able to provide maximum thrust in ahead, astern, or to the side. Accord- ing to KMY and ABB, both members

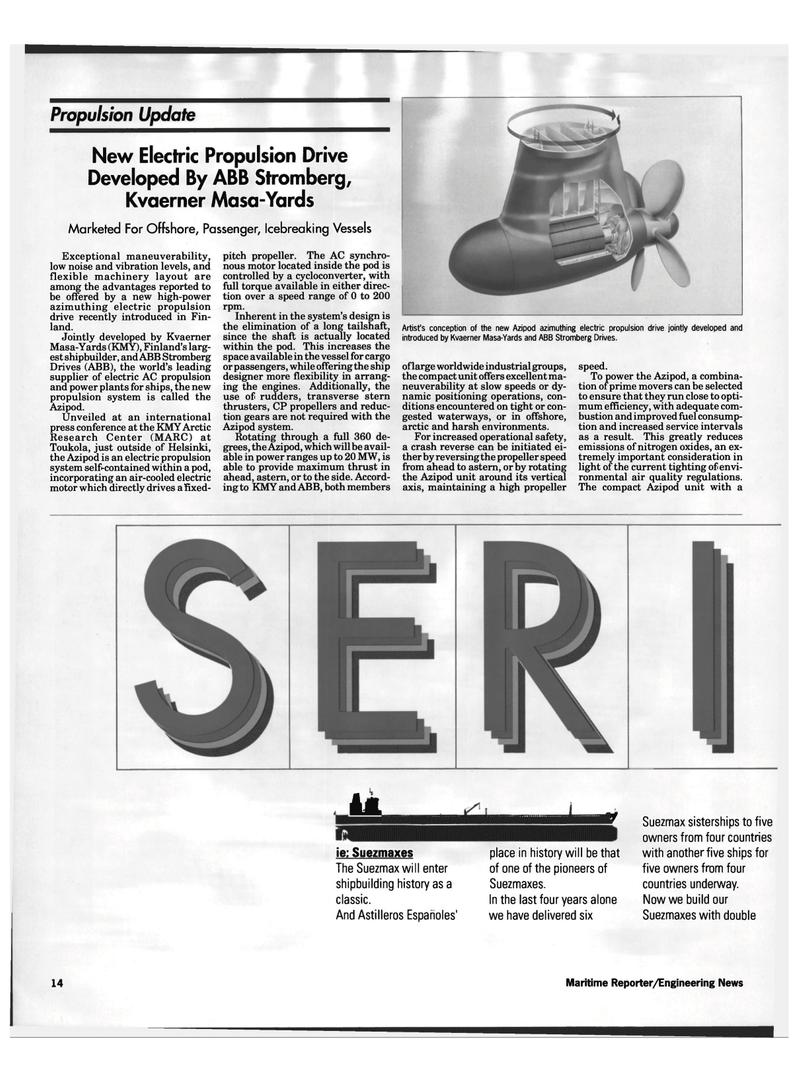

Artist's conception of the new Azipod azimuthing electric propulsion drive jointly developed and introduced by Kvaerner Masa-Yards and ABB Stromberg Drives. of large worldwide industrial groups, the compact unit offers excellent ma- neuverability at slow speeds or dy- namic positioning operations, con- ditions encountered on tight or con- gested waterways, or in offshore, arctic and harsh environments.

For increased operational safety, a crash reverse can be initiated ei- ther by reversing the propeller speed from ahead to astern, or by rotating the Azipod unit around its vertical axis, maintaining a high propeller speed.

To power the Azipod, a combina- tion of prime movers can be selected to ensure that they run close to opti- mum efficiency, with adequate com- bustion and improved fuel consump- tion and increased service intervals as a result. This greatly reduces emissions of nitrogen oxides, an ex- tremely important consideration in light of the current tighting of envi- ronmental air quality regulations.

The compact Azipod unit with a it tf ie: Suezmaxes

The Suezmax will enter shipbuilding history as a classic.

And Astilleros Espanoles' place in history will be that of one of the pioneers of

Suezmaxes.

In the last four years alone we have delivered six

Suezmax sisterships to five owners from four countries with another five ships for five owners from four countries underway.

Now we build our

Suezmaxes with double 14 Maritime Reporter/Engineering News

11

11

13

13