Page 38: of Maritime Reporter Magazine (June 1992)

Read this page in Pdf, Flash or Html5 edition of June 1992 Maritime Reporter Magazine

Ship Repair & Maintenance

Over $3.5 billion is requested for ship repair and maintenance in the proposed FY 1993 budget (see Table 5). Ship Depot Level Repair funding decreases in FY 1993, as previously deferred maintenance and Desert

Storm-related maintenance is com- pleted during FY 1992. FY 1993 fund- ing supports 10 overhauls, includ- ing an extensive COH for the air- craft carrier USS John F. Kennedy (CV-67), the overhaul of the ballistic missile submarine USS Ohio (SSBN- 726) and the refueling overhaul of two Los Angeles Class submarines.

Research & Development

Over $8.5 billion has been re- quested for Research, Development,

Testing & Evaluation (RDT&E).

Program funding for the contin- ued development of the electric drive has been proposed at $99.2 million, a significant increase over FY 1992's funding of $39.3 million.

Support Equipment

The appropriation requestof $5.86 billion in FY 1993 will fund the pro- curement of ship support equipment, communications and electronics equipment, aviation support equip- ment, ordnance support equipment, civil engineering, supply and com- mand support equipment, and spares and repair parts. Table 6 shows details.

The FY 1993 program includes

Ships Support Equipment budgeted at $1.39 billion. Items procured in this budget activity include propul- sion, safety and pollution control equipment, as well as design efforts associated with the modernization of Navy platforms.

Communication and electronics equipment is budgeted at $2.13 bil- lion in FY 1993. This Budget Activ- ity funds the procurement and in- stallation of the latest communica- tion systems such as the SHF Satcom ship terminal, as well as the im- provement of current weapon sys- tems.

Overall, the Navy market, albeit a smaller one, is still very lucrative.

Combined with expenditures from other military and governmental sectors, the Naval marine market should exceed $30 billion in FY 1993 (see May issue of MARITIME RE-

PORTER for details).

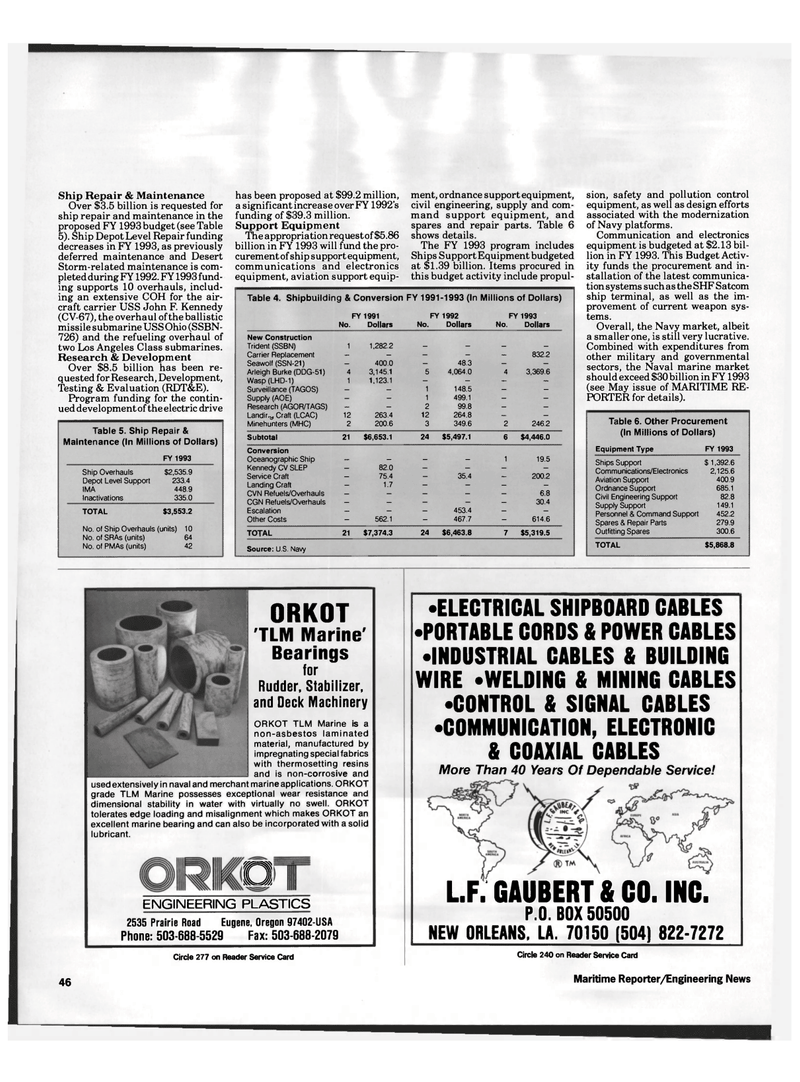

Table 5. Ship Repair &

Maintenance (In Millions of Dollars)

FY 1993

Ship Overhauls $2,535.9

Depot Level Support 233.4

IMA 448.9

Inactivations 335.0

TOTAL $3,553.2

No. of Ship Overhauls (units) 10

No. of SRAs (units) 64

No. of PMAs (units) 42

Table 4. Shipbuilding & Conversion FY 1991-1993 (In Millions of Dollars)

FY 1991 FY 1992 FY 1993

No. Dollars No. Dollars No. Dollars

New Construction

Trident (SSBN) 1 1,282.2 - - - -

Carrier Replacement — — — - — 832.2

Seawolf (SSN-21) - 400.0 — 48.3 — —

Arleigh Burke (DDG-51) 4 3,145.1 5 4,064.0 4 3,369.6

Wasp (LHD-1) 1 1,123.1 — — — —

Surveillance (TAGOS) — — 1 148.5 — —

Supply (AOE) - - 1 499.1 - —

Research (AGOR/TAGS) - — 2 99.8 - —

Landir.a Craft (LCAC) 12 263.4 12 264.8 — —

Minehunters (MHC) 2 200.6 3 349.6 2 246.2

Subtotal 21 $6,653.1 24 $5,497.1 6 $4,446.0

Conversion

Oceanographic Ship - - - - 1 19.5

Kennedy CV SLEP — 82.0 — — — —

Service Craft — 75.4 — 35.4 — 200.2

Landing Craft - 1.7 • — - — -

CVN Refuels/Overhauls — — — — — 6.8

CGN Refuels/Overhauls — — — — — 30.4

Escalation — — — 453.4 — —

Other Costs - 562.1 - 467.7 - 614.6

TOTAL 21 $7,374.3 24 $6,463.8 7 $5,319.5

Source: U.S. Navy

Table 6. Other Procurement (In Millions of Dollars)

Equipment Type FY 1993

Ships Support $ 1,392.6

Communications/Electronics 2,125.6

Aviation Support 400.9

Ordnance Support 685.1

Civil Engineering Support 82.8

Supply Support 149.1

Personnel & Command Support 452.2

Spares & Repair Parts 279.9

Outfitting Spares 300.6

TOTAL $5,868.8

Q

ENGINEERING PLASTICS 2535 Prairie Road Eugene, Oregon 97402-USA

Phone: 503-688-5529 Fax: 503-688-2079

Circle 277 on Reader Service Card •ELECTRICAL SHIPBOARD CABLES •PORTABLE CORDS & POWER CABLES •INDUSTRIAL CABLES & BUILDING

WIRE *WELDING & MINING CABLES •CONTROL & SIGNAL CABLES •COMMUNICATION, ELECTRONIC & COAXIAL CABLES

More Than 40 Years Of Dependable Service!

L.F. GAUBERT & CO. INC.

P.O. BOX 50500

NEW ORLEANS, LA. 70150 (504) 822-7272

Circle 240 on Reader Service Card

ORKOT 'TLM Marine'

Bearings for

Rudder, Stabilizer, and Deck Machinery

ORKOT TLM Marine is a non-asbestos laminated material, manufactured by impregnating special fabrics with thermosetting resins and is non-corrosive and used extensively in naval and merchant marine applications. ORKOT grade TLM Marine possesses exceptional wear resistance and dimensional stability in water with virtually no swell. ORKOT tolerates edge loading and misalignment which makes ORKOT an excellent marine bearing and can also be incorporated with a solid lubricant. 46 Maritime Reporter/Engineering News

37

37

39

39