Page 92: of Maritime Reporter Magazine (June 1992)

Read this page in Pdf, Flash or Html5 edition of June 1992 Maritime Reporter Magazine

Phase I Of Oceaneering

Production Systems

EWT JIP Completed

Phase I of Oceaneering Produc- tion Systems' extended well test joint industry project (EWT JIP) has been completed. Companies supporting the project were Marathon Oil, Arco,

BP Exploration, Elf, Mobil Research and Development Corporation, and

Shell Offshore. Subcontractors sup- porting the project were ABB Vetco

Gray, Aker Omega Marine, FSSL,

Mustang Engineering and

Wellstream. The primary goal of

Phase I was to determine the techni- cal and economic feasibility of de- signing and building a vessel ca- pable of testing hydrocarbon forma- tions in very deep water in the Gulf of Mexico.

Some of the tasks investigated during the project included develop- ment of the EWT design basis; de- termination of vessel configuration as well as comparison of new build versus conversion; station-keeping methods; process plant design; methods of utilizing associated gas in lieu of flaring; design of flowlines and risers; design of subsea produc- tion systems; and investigation of suitable downhole instrumentation methods.

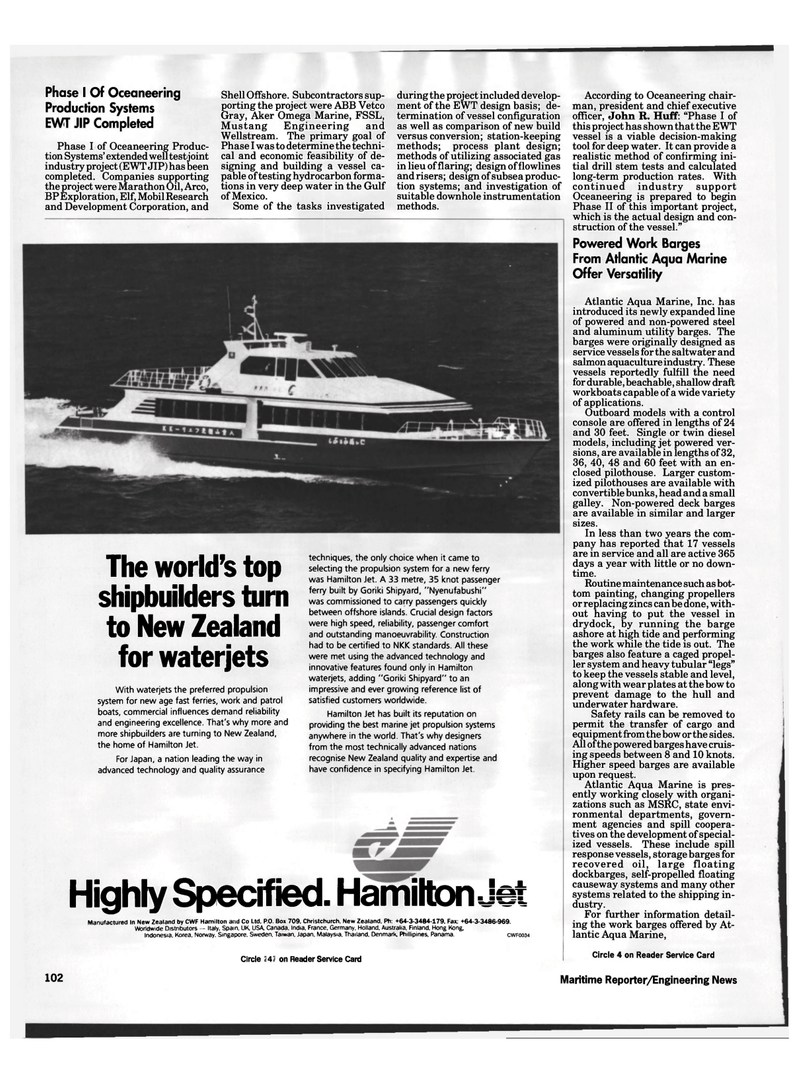

The world's top shipbuilders turn to New Zealand for waterjets

With waterjets the preferred propulsion system for new age fast ferries, work and patrol boats, commercial influences demand reliability and engineering excellence. That's why more and more shipbuilders are turning to New Zealand, the home of Hamilton Jet.

For Japan, a nation leading the way in advanced technology and quality assurance techniques, the only choice when it came to selecting the propulsion system for a new ferry was Hamilton Jet. A 33 metre, 35 knot passenger ferry built by Goriki Shipyard, "Nyenufabushi" was commissioned to carry passengers quickly between offshore islands. Crucial design factors were high speed, reliability, passenger comfort and outstanding manoeuvrability. Construction had to be certified to NKK standards. All these were met using the advanced technology and innovative features found only in Hamilton waterjets, adding "Goriki Shipyard" to an impressive and ever growing reference list of satisfied customers worldwide.

Hamilton Jet has built its reputation on providing the best marine jet propulsion systems anywhere in the world. That's why designers from the most technically advanced nations recognise New Zealand quality and expertise and have confidence in specifying Hamilton Jet.

Highly Specified. Hamilton Jet

Manufactured In New Zealand by CWF Hamilton and Co Ltd. P.O. Box 709. Christchurch. New Zealand. Pti: +64-3-3484-179. Fax: +64-3-3486-969. \Atorldwide Distributors — Italy, Spain. UK, USA. Canada. India. France. Germany, Holland. Australia, Finland, Hong Kong,

Indonesia. Korea. Norway. Singapore. Sweden. Taiwan. Japan. Malaysia, Thailand, Denmark. Ptiillipines, Panama. CWF0034

Circle 349 on Reader Service Card

According to Oceaneering chair- man, president and chief executive officer, John R. Huff: "Phase I of this proj ect has shown that the EWT vessel is a viable decision-making tool for deep water. It can provide a realistic method of confirming ini- tial drill stem tests and calculated long-term production rates. With continued industry support

Oceaneering is prepared to begin

Phase II of this important project, which is the actual design and con- struction of the vessel."

Powered Work Barges

From Atlantic Aqua Marine

Offer Versatility

Atlantic Aqua Marine, Inc. has introduced its newly expanded line of powered and non-powered steel and aluminum utility barges. The barges were originally designed as service vessels for the saltwater and salmon aquaculture industry. These vessels reportedly fulfill the need for durable, beachable, shallow draft workboats capable of a wide variety of applications.

Outboard models with a control console are offered in lengths of 24 and 30 feet. Single or twin diesel models, including jet powered ver- sions, are available in lengths of 32, 36, 40, 48 and 60 feet with an en- closed pilothouse. Larger custom- ized pilothouses are available with convertible bunks, head and a small galley. Non-powered deck barges are available in similar and larger sizes.

In less than two years the com- pany has reported that 17 vessels are in service and all are active 365 days a year with little or no down- time.

Routine maintenance such as bot- tom painting, changing propellers or replacing zincs can be done, with- out having to put the vessel in drydock, by running the barge ashore at high tide and performing the work while the tide is out. The barges also feature a caged propel- ler system and heavy tubular "legs" to keep the vessels stable and level, along with wear plates at the bow to prevent damage to the hull and underwater hardware.

Safety rails can be removed to permit the transfer of cargo and equipment from the bow or the sides.

All of the powered barges have cruis- ing speeds between 8 and 10 knots.

Higher speed barges are available upon request.

Atlantic Aqua Marine is pres- ently working closely with organi- zations such as MSRC, state envi- ronmental departments, govern- ment agencies and spill coopera- tives on the development of special- ized vessels. These include spill response vessels, storage barges for recovered oil, large floating dockbarges, self-propelled floating causeway systems and many other systems related to the shipping in- dustry.

For further information detail- ing the work barges offered by At- lantic Aqua Marine,

Circle 4 on Reader Service Card 102 Maritime Reporter/Engineering News

91

91

93

93