Page 2nd Cover: of Maritime Reporter Magazine (September 1992)

Read this page in Pdf, Flash or Html5 edition of September 1992 Maritime Reporter Magazine

ON LAND

Documented case histories available for ACS separators now working at electric generating plants, refineries and chemical plants.

AT SEA

Because of their proven high speed and high efficiency, ACS oil-water separators were chosen for use aboard all 16

MSRC vessels recently built to respond to spills in U.S. coast waters.

ACS Industries., Separations Technology Group 14208 Industry Road • Houston, Texas 77053

Telephone (713) 434-0934 or (800) 231-0077

Telefax (713) 433-6201

Established in 1939 | INDUSTRIES, INC.

Land and INDUSTRIES, INC.

Oil-wate separators MM for environmental treatment of industrial wastewater and marine skimmer discharge

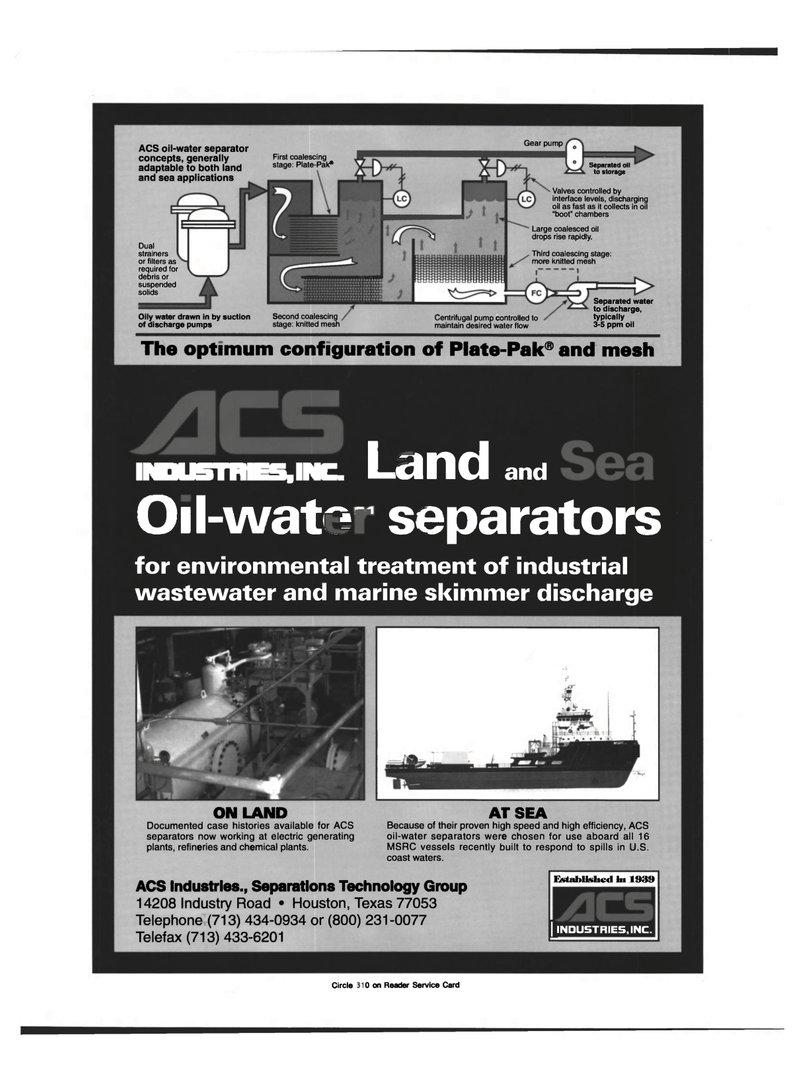

The optimum configuration of Plate-Pak® and mesh

ACS oil-water separator concepts, generally adaptable to both land and sea applications

Gear pump

First coalescing stage: Plate-Pak® Separated oil to storage

Valves controlled by interface levels, discharging oil as fast as it collects in oil "boot" chambers

Large coalesced oil drops rise rapidly.

Third coalescing stage: more knitted mesh

Second coalescing stage: knitted mesh

Centrifugal pump controlled to maintain desired water flow

Separated water to discharge, typically 3-5 ppm oil

Dual strainers or filters as required for debris or suspended solids

Oily water drawn in by suction of discharge pumps

Circle 200 on Reader Service Card ^Signal

Cover

Cover

1

1