Page 65: of Maritime Reporter Magazine (December 1993)

Read this page in Pdf, Flash or Html5 edition of December 1993 Maritime Reporter Magazine

Inexa Profit Bulb Flat Technology: To Fight

Corrosion, Ease Maintenance And Conversion

Company's bulb flats to be featured on Kvaerner-built LNG tankers

Hitachi Zosen Delivers Variety Of New

Vessels

The Inexa Profil bulb flat line was expanded to include the Jumbo Bulb Flat, a product touted by the manufacturer as an ideal reinforcement solu- tion for the lower side sections of double-hulled tankers and carriers.

The bulb flat line is a compact, rounded-edge design which reportedly simplifies maintenance and rust prevention. The bulb flat allows easy access for all types of surface preparation, and features no sharp corners which reportedly can prove difficult to reach. Up to the introduction of the Jumbo Bulb Flat, the one serious drawback to the bulb flat line was that it was only available in sizes up to 430mm. But the Jumbo is available in sizes from 400mm to 650mm, a dramatic exten- sion in the bulb flat range. The profile is, as are all smaller bulb flats, rust resistant. Shotblasting, coating, inspection and cleaning are all simpli- fied, and the surface area is reportedly smaller than a comparable T-section or angle—a fact which can help lower production and mainte- nance costs.

While the bulb flat design is widely accepted now in ship design overseas, according to Karl-

David Sundberg, the company's president,

Inexa Profil has an interested marketing eye pointed at the U.S. market, and the expected new business as traditional defense companies cap- ture commercial business. "We are excited about what goes on here, this market is very interesting for us," Mr. Sundberg said. "U.S. yards must capitalize on the latest design trends to make the leap to commercial, and we can help them as we provide the technol- ogy and experience to make them proficient."

Finishing touches being made to one of Inexa Profil's new jumbo bulb flats; seen here in the largest 650mm size.

Expanding Product Lines

To further enhance its business, Inexa ac- quired the former Rockment A/S of Denmark.

The new name for the company is Inexa Panel, and it offers a complete TNF (Thermal insula- tion, Noise reduction and Fire protection) brand range of wall, ceiling and floor panels. Inexa

Panel has been a market leader for 20 years, and the TNF brand is an industry standard. Among its accomplishments: the pioneered use of "softcore" panels with the installation of TNF on the Golden Odyssey in 1974.

The contract for delivery of shipbuilding sections from Inexa Profil is signed in Lulea on October 28, by purchasing manager Jorma

Joikinen, Kvaerner Masa Yards in Turku (left), and Inexa's managing director Christer Olson. The signing is supervised by Inexa Profil's chairman of the board Karl-David Sundberg (standing left) and

Kvaerner Masa Yard's manager Robert Stenius.

Inexa Wins Kvaerner Contract

Inexa was awarded a contract from the Finn- ish Kvaerner Masa-Yards to supply bulb flats as stiffening elements for the four LNG ships to be built by Kvaerner Masa-Yards shipyard in Turku for Abu Dhabi National Oil Co. "The fact that we have been able to secure the complete order for bulb sections for this prestigious project in the face of strong international competition strength- ens our position as a world leading supplier of shipbuilding sections," said Inexa's Christer

Olson.

For free information on Inexa Profil's Bulb

Flat line of products,

Circle 30 on Reader Service Card

For free information on Inexa Panel's TNF panel line,

Circle 31 on Reader Service Card

Rowland Becomes Chairman Of

AAPA'S U.S. Delegation

Charles M. Rowland, executive director of the Canaveral Port Authority, was officially in- stalled as chairman of the U.S. Delegation of the

American Association of Port Authorities (AAPA), at its 82nd Annual Convention held recently in

Halifax, Nova Scotia.

Mr. Rowland has served as executive direc- tor of the Canaveral Port Authority since March 1980.

The AAPA is an alliance of 120 seaports in 17 nations of the Western Hemisphere. The organi- zation promotes the common interests of ports and provides leadership on trade, transporta- tion, environmental and other issues related to port development and operations.

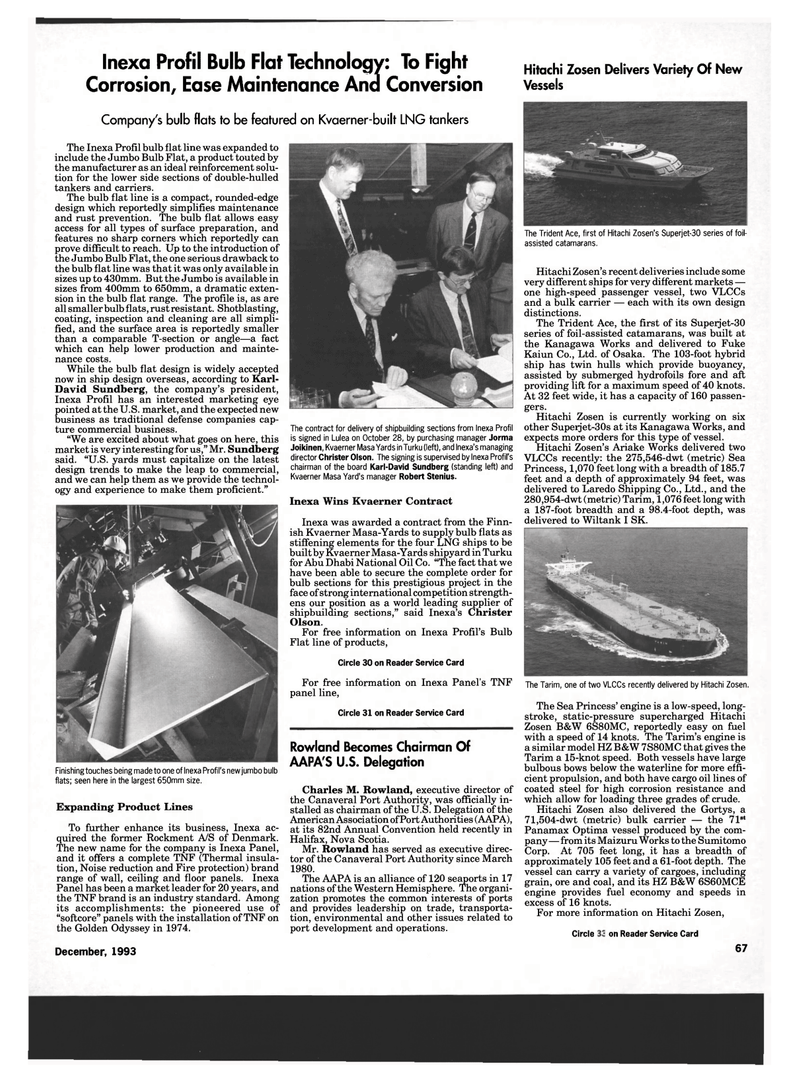

The Trident Ace, first of Hitachi Zosen's Superjet-30 series of foil- assisted catamarans.

Hitachi Zosen's recent deliveries include some very different ships for very different markets — one high-speed passenger vessel, two VLCCs and a bulk carrier — each with its own design distinctions.

The Trident Ace, the first of its Superjet-30 series of foil-assisted catamarans, was built at the Kanagawa Works and delivered to Fuke

Kaiun Co., Ltd. of Osaka. The 103-foot hybrid ship has twin hulls which provide buoyancy, assisted by submerged hydrofoils fore and aft providing lift for a maximum speed of 40 knots.

At 32 feet wide, it has a capacity of 160 passen- gers.

Hitachi Zosen is currently working on six other Superjet-30s at its Kanagawa Works, and expects more orders for this type of vessel.

Hitachi Zosen's Ariake Works delivered two

VLCCs recently: the 275,546-dwt (metric) Sea

Princess, 1,070 feet long with a breadth of 185.7 feet and a depth of approximately 94 feet, was delivered to Laredo Shipping Co., Ltd., and the 280,954-dwt (metric) Tarim, 1,076 feet long with a 187-foot breadth and a 98.4-foot depth, was delivered to Wiltank I SK.

The Tarim, one of two VLCCs recently delivered by Hitachi Zosen.

The Sea Princess' engine is a low-speed, long- stroke, static-pressure supercharged Hitachi

Zosen B&W 6S80MC, reportedly easy on fuel with a speed of 14 knots. The Tarim's engine is a similar model HZ B&W 7S80MC that gives the

Tarim a 15-knot speed. Both vessels have large bulbous bows below the waterline for more effi- cient propulsion, and both have cargo oil lines of coated steel for high corrosion resistance and which allow for loading three grades of crude.

Hitachi Zosen also delivered the Gortys, a 71,504-dwt (metric) bulk carrier — the 71st

Panamax Optima vessel produced by the com- pany —from its Maizuru Works to the Sumitomo

Corp. At 705 feet long, it has a breadth of approximately 105 feet and a 61-foot depth. The vessel can carry a variety of cargoes, including grain, ore and coal, and its HZ B&W 6S60MCE engine provides fuel economy and speeds in excess of 16 knots.

For more information on Hitachi Zosen,

Circle 276 on Reader Service Card

December, 1993 67

64

64

66

66